DA7000 SERIES GENERATORS • OPERATION AND PARTS MANUAL — REV. #5 (01/20/11) — PAGE 33

MAINTENANCE

Maintenance

Perform the scheduled maintenance procedures as defi ned

by Table 8 and below:

Engine Oil

Every 100 hours: Change engine oil after the fi rst 50 hours

of operation and 100 hours thereafter. Always check the

crankcase oil level prior to each use, or when the fuel tank

is fi lled. Insuffi cient oil may cause severe engine damage.

Make sure generator is level when checking oil level. The

oil level must be between the two notches on the dipstick

as shown in Figure 8.

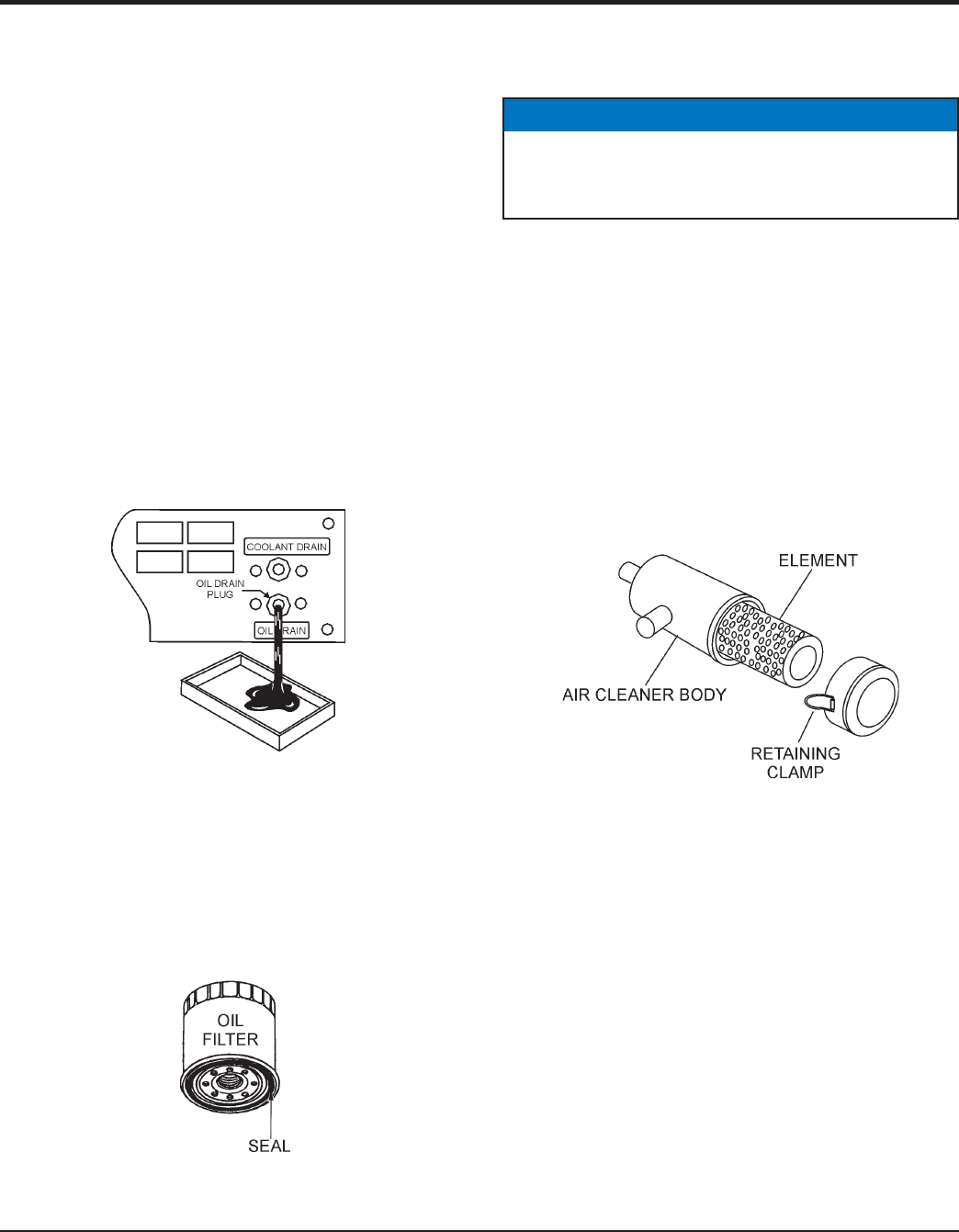

1. Remove engine oil drain plug located at the bottom of

the generator enclosure (Figure 29) and drain oil from

crankcase.For best results drain oil while engine is

warm. Reinstall oil drain plug, and add engine oil as

specifi ed in Table 5. Crankcase oil capacity is 2.64 qts.

(2.5 liters).

Figure 29. Engine Oil Drain Plug

Oil Filter Cartridge

Every 200 hours: Replace the engine oil fi lter cartridge

after every 200 hours of operation.

1. Clean oil fi lter mounting base, and coat oil fi lter seal

(Figure 30) with clean engine oil.

Figure 30. Oil Filter Cartridge

2. Screw on new oil fi lter by hand until seal contacts the

fi lter mounting base. Install drain bolt with sealing

washer and hand tighten.

3. Replace engine oil with recommended type oil as listed

in Table 5. For engine oil capacity, see Table 2 (engine

specifi cations). Fill to upper limit as shown in Figure 8.

Engine Air Cleaner

Every 50 hours: The air cleaner employed on the

KUBOTA Z482 series engines is a dry type, NEVER

apply oil to it. If generator is used in severe dusty areas

service air cleaner element more frequently.

1. Release the air cleaner retaining clamps (Figure 31)

and remove the air cleaner element.

Figure 31. Air Cleaner

2. Wipe the inside of the air cleaner with a clamp cloth and

remove all dust and debris that may have accumulated

inside air cleaner body.

3. Tap the edge of element lightly to allow heavy dust

build-up to fall off.

4. Tap the paper fi lter element (Figure 31) several times on

a hard surface to remove dirt, or blow compressed air

[not exceeding 99 psi (686 kPa, 2.1 kgf/cm2)] through

the fi lter element from from the inside while turning

the element. NEVER brush off dirt. Brushing will force

dirt into the fi bers.

5. Replace the fi lter element once a year or every six

cleanings or if it is excessively dirty

NOTICE

When installing the oil fi lter, coat rubber seal with a

small amount of lubricant (motor oil). DO NOT over-

tighten cartridge. Hand tighten only.