25

Fig. 59

Spring

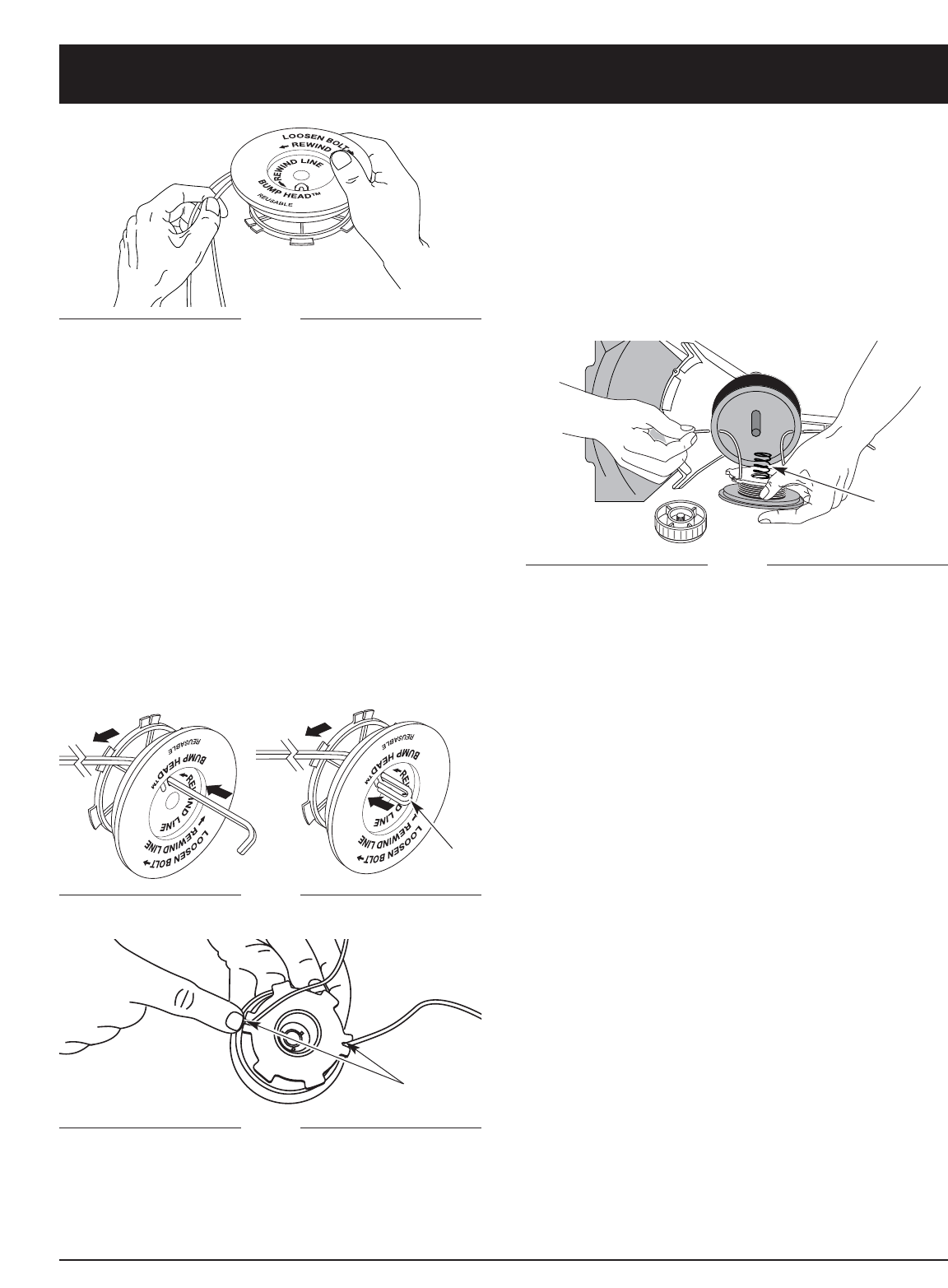

13. Insert the ends of the line through the eyelets in the

outer spool and place inner reel with spring inside the

outer spool (Fig. 59). Push the inner reel and outer

spool together. While holding the inner reel and outer

spool, grasp the ends and pull firmly to release the

line from the holding slots in the reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

14. Hold the inner reel in place and install the bump knob

by turning counterclockwise. Tighten securely.

MAINTENANCE AND REPAIR INSTRUCTIONS

Installing a Prewound Wheel

1. Hold the outer spool with one hand and unscrew the

bump knob clockwise (Fig. 51). Inspect the bolt inside

the bump knob to make sure it moves freely. Replace

the bump knob if damaged.

2. Remove the old inner reel from the outer spool

(Fig. 51).

3. Remove the spring from the old inner reel

(Fig. 51).

4. Place the spring in the new inner reel.

NOTE:The spring must be assembled on the inner reel

before reassembling the cutting attachment.

5. Insert the ends of the line through the eyelets in the

outer spool (Fig. 59).

6. Place the new inner reel inside the outer spool. Push the

inner reel and outer spool together. While holding the

inner reel and outer spool, grasp the ends and pull firmly

to release the line from the holding slots in the spool.

7. Hold the inner reel in place and install the bump knob

by turning counterclockwise. Tighten securely.

Fig. 58

SplitLine™ Installation

8. Take approximately 2.5 m (8 feet) of new trimming

line. Insert one end of the line through one of the two

holes in the inner reel (Fig. 57). Pull the line through

the inner reel until only about 4 inches is left out.

9. Insert the end of the line into the open hole in the

inner reel and pull the line tight to make the loop as

small as possible (Fig. 57).

10. Before winding, split the line back about 6 inches.

11. Wind the line in tight even layers in the direction

indicated on the inner reel.

NOTE: Failure to wind the line in the direction indicated will

cause the cutting attachment to operate incorrectly.

12. Insert the ends of the line into the two holding slots

(Fig. 58).

Fig. 57

Fig. 56

Loop

Holding Slots