15

K. Transport

• Log splitter is equipped with two 10” dia. wheels to make it easy to move around.

• If you’d like to move your log splitter to different locations, secure the unit during transport to prevent damage or injury.

Always tighten the bleed screw to prevent oil spill.

WARNING

BEFORE PERFORMING ANY MAINTENANCE BE SURE THAT:

• LOG SPLITTER IS DISCONNECTED FROM POWER SOURCE.

• PUSHER PLATE IS FULLY RETRACTED (RETURNED TO THE LOWEST POSITION)

AND NO RESIDUAL HYDRAULIC ENERGY IS LEFT IN THE SYSTEM.

• OIL HAS COOLED.

L. Maintenance

Area Maintenance procedure Frequency

Inspect Hydraulic fluid level

Using an Adjustable Wrench, unscrew

the Dipstick.

Clean the Dipstick and inspect it to check

that the oil level is between the two notches

on the stem.

(See section G for instructions)

Before each use

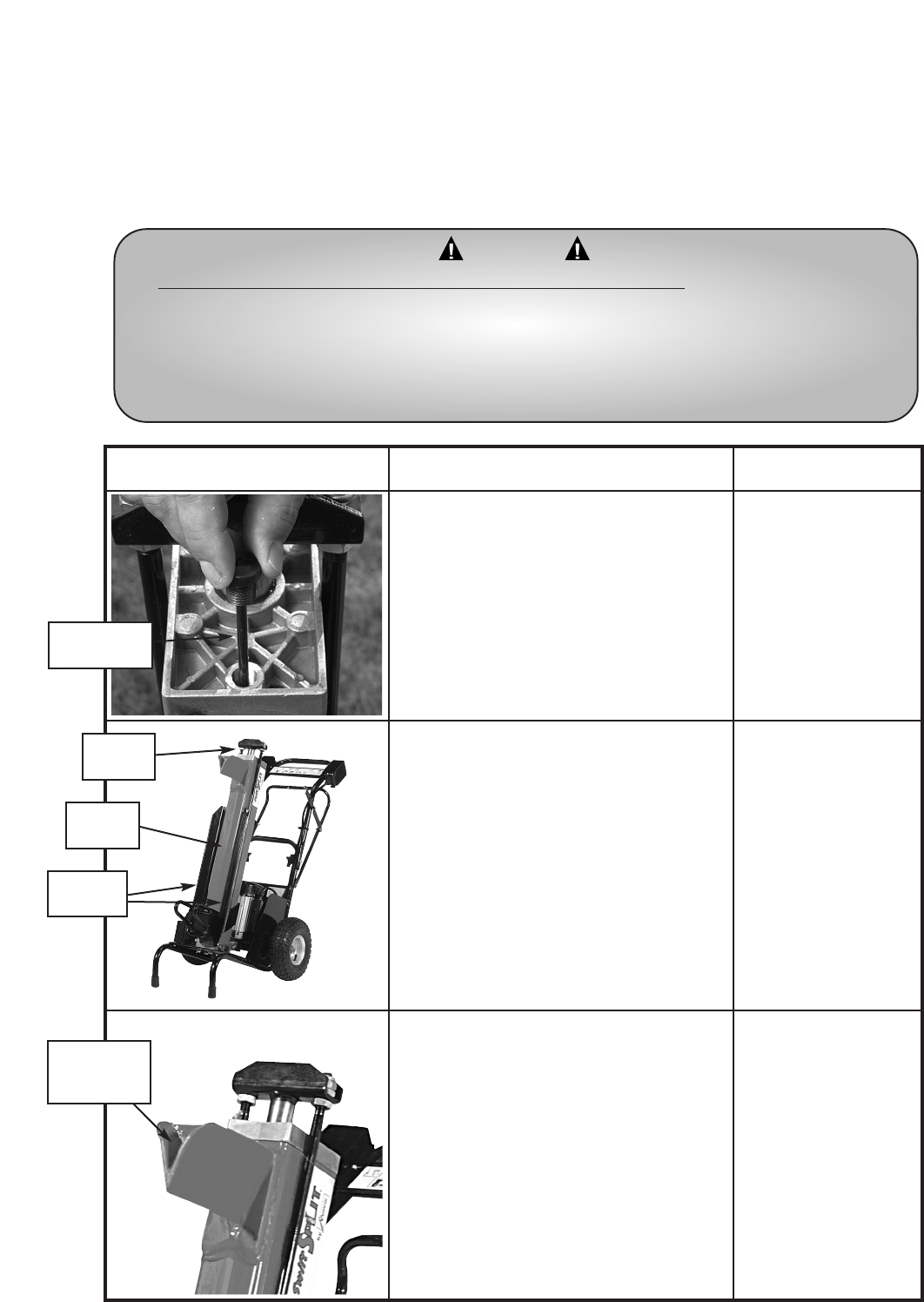

Inspect/Lubricate

Log Ram, Vertical Beam

and Guides

Use #2 Lithium Grease

Before each use

Inspect/Sharpen

Splitting Wedge

(See section J for sharpening instructions)

Before each use

DIPSTICK

RAM

GUIDES

BEAM

SPLITTING

WEDGE