13

IMPORTANT! DO NOT MIX FLUID BRANDS AND TYPES! DO NOT USE OTHER GRADE OILS.

WARNING

BEFORE PERFORMING ANY MAINTENANCE BE SURE THA

T

:

• LOG SPLITTER IS DISCONNECTED FROM THE POWER SOURCE.

• PUSHER PLATE IS FULLY RETRACTED (RETURNED TO THE LOWEST POSITION)

AND NO RESIDUAL HYDRAULIC ENERGY IS LEFT IN THE SYSTEM.

• OIL HAS COOLED.

• YOUR MACHINE IS CLEAN. DO NOT CONTAMINATE HYDRAULIC FLUID.

CONTAMINANTS OF HYDRAULIC FLUID INCLUDE SOLID PARTICLES, AIR, WATER

OR ANY OTHER MATTER THAT IMPAIRS THE FUNCTION OF THE FLUID.

CONTAMINATION ACCELERATES WEAR OF HYDRAULIC COMPONENTS.

I. How to change the hydraulic oil

Oil should be changed after every 100 hours of operation.

The drain port is located under the unit

Recommended Oil

Types:

Shell Tellus T22

Aral Vitam GF22

SP Energol HCP22

Mobil DTE11 or equivalent

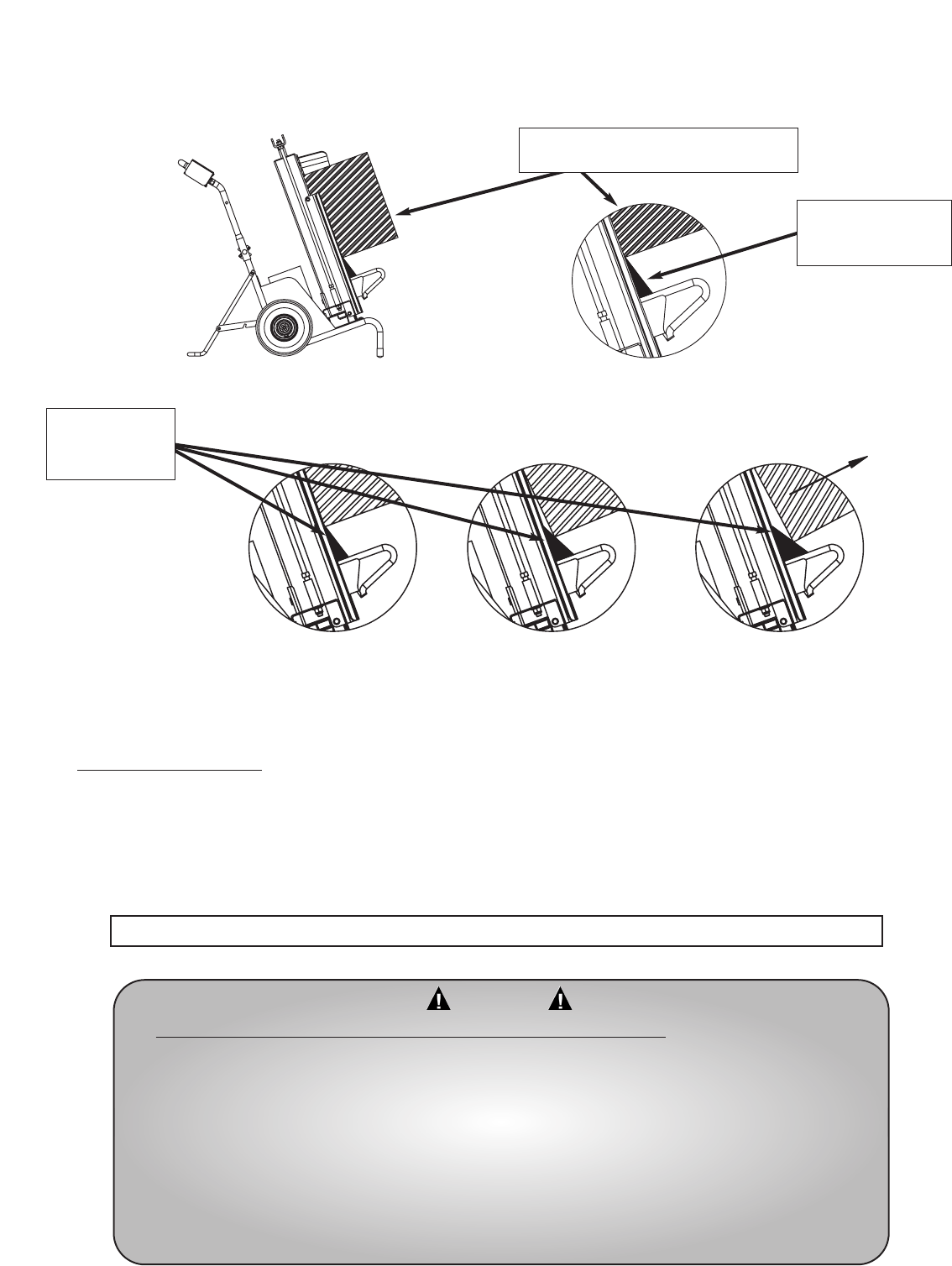

Wooden Wedge

Log is jammed on the wedge

Different size

wooden wedges

2. Place a piece of wood shaped as wedge under the jammed log and activate the pressure plate of the log splitter to push it up

and under the jammed log. Repeat this process using larger wooden wedges until the jammed log is released.