12

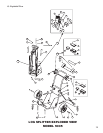

MAXIMUM LOG SIZE FOR THE SWIFT SPLIT IS 20” LONG X 12” DIA.

5. Place the log on the pressure plate of the machine. Be sure that the body of the log is lying firmly against the vertical beam

of the log splitter and the end of the log is well supported by the pressure plate. If the log tends to wobble, reposition it by

turning it. The supporting guides help to keep the log at the center or the log splitter.

• If the log moves away from the beam, retract the pressure plate and turn the log 90 degrees. Do not force the log on the

tip part of the blade; this can damage blade welds and the body of the machine.

6. While operating the log splitter, always be sure of a safe and secure operating position and stand inside of the

Operator Zone.

7. Activate pressure plate, by depressing both switches and keep holding them until split pieces of the log fall away. Then,

release them. This will cause the pressure plate to retract to its starting position.

8. When the job is finished and you are ready to store your log splitter, tighten the bleed screw to prevent oil leakage during

storage time.

WARNING

• NEVER REQUEST THE ASSISTANCE OF ANOTHER PERSON TO HELP YOU REMOVE

A JAMMED LOG!

• NEVER REMOVE LOG JAMMED ON THE SPLITTING WEDGE WITH YOUR HANDS!

• KEEP YOUR HANDS AND BODY PARTS AWAY FROM THE OPEN SPLITS AND

CRACKS IN THE LOG. THE WOOD CAN CLOSE IN SUDDENLY AND CAUSE INJURY.

• NEVER TRY TO REMOVE THE JAMMED LOG BY HITTING IT WITH A HAMMER OR

ANY OTHER OBJECT; THIS CAN DAMAGE THE HYDRAULIC PUMP COVER, MOTOR

COVER OR OTHER PARTS OF THE LOG SPLITTER.

H. Removal of logs jammed on the wedge

1. Release both switches and wait until pressure plate is fully retracted and returns in the lowest position.