6

1. Loosen mounting nut and adjust the chain tension by

turning the tensioner screw

2. Hold unit vertically, and tighten mounting nut

3. Move saw chain backwards on guide bar by hand. Saw

chain should move freely on guide bar if it is in proper

mesh with the sprocket. If saw chain is difficult to rotate or

binds on guide bar, it is too tight. Re-adjust if necessary.

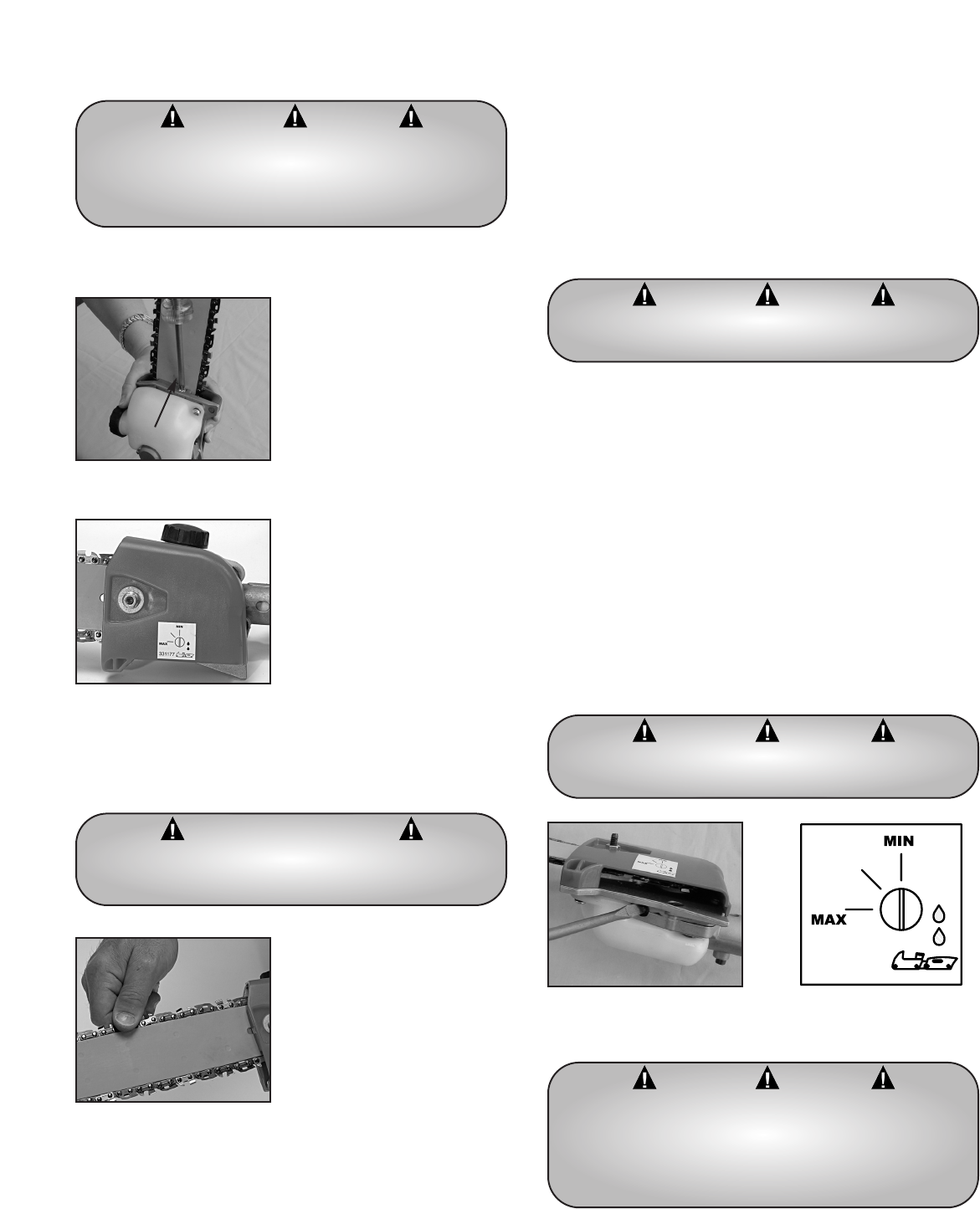

Adjusting saw chain tension

1. Power pruning mechanism is equipped with the automatic

oiling system that can be adjusted in the field. The saw

chain bar, and chain are lubricated when chain rotates. The

pump is set at the factory to a minimum flow rate.

2. Remove oil fill cap and fill reservoir with a quality, low

viscosity guide bar and saw chain oil. Tighten the cap

securely.

3. After starting the motor, run the chain at medium speed

and check the saw chain. Very little visible oil on the saw

chain will provide sufficient lubrication.

4. The oil tank will provide about 40 min. of cutting time

(when set to a minimum flow rate). Refill the oil tank as

needed.

5. A temporary increase in oil flow is recommended when

cutting hardwood or wood showing a large amount of sap.

This will speed oil consumption, and require more frequent

oil tank refills.

6. To adjust oil pump to max, the control screw must be

pressed in slightly prior to turning. Failure to do so

could damage the pump or screw.

7. Wipe debris from around the oil fill cap prior to re-filling

the oil reservoir.

Lubricating the guide bar and chain

WARNING DANGER

IT IS VERY IMPORTANT TO MAINTAIN THE

PROPER CHAIN TENSION. RAPID WEAR OF THE

GUIDE BAR OR THE CHAIN COMING OFF EASILY

CAN BE CAUSED BY IMPROPER TENSION.

WARNING DANGER

NEVER FILL THE OIL TANK OR ADJUST THE OIL

FLOW WHILE MOTOR IS RUNNING.

DISCONNECT POWER CORD FROM THE

POWER SOURCE FIRST.

WARNING DANGER

THE OIL FLOW RATE ADJUSTING SCREW HAS 3

INCREMENTAL SETTINGS.

WARNING DANGER

TO PREVENT PLASTIC DETERIORATION, DO NOT

USE SYNTHETIC OR SILICONE BASED OIL.

WARNING – DANGER

BE SURE UNIT IS UNPLUGGED BEFORE

MAKING ANY ADJUSTMENTS.