9

G

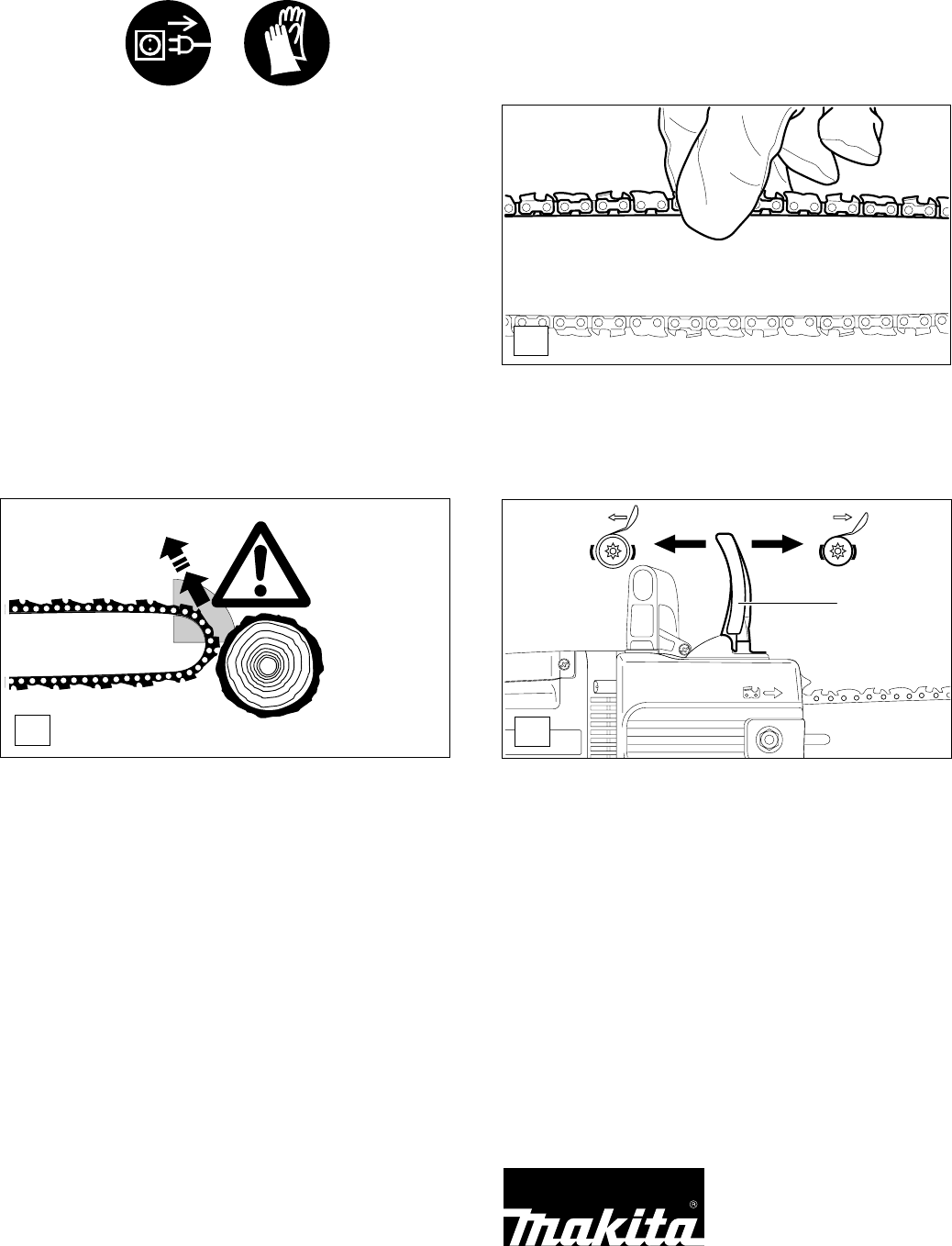

The chain has the proper tension when it lies against the

bottom edge of the guide bar and can be easily pulled by hand

about 5 mm (a little under 1/4") up from the guide bar.

Check the chain tension frequently - new chains tend to get

longer during use!

When checking the chain tension the motor must be switched

off and the power supply plug pulled out.

HINT:

Use 2 or 3 saw chains alternately for even wear of the chains,

sprocket and guide bar running surfaces.

In order to guarantee a uniform wear of the groove in the bar the

bar should be turned over whenever replacing the chain.

Checking the chain tension

11

12

The UC 3000, UC 3500 and UC 4000 comes with an inertial

chain brake as standard equipment. The chain brake engages

automatically in case of kickback, which is caused by the tip

contacting wood while the saw is running (see "SAFETY

PRECAUTIONS", page 5).

The chain will stop within a fraction of a second.

Chain brake

H

Engaging the chain brake (braking)

In case of kickback the chain brake is engaged automatically

by inertial motion of the hand guard (I/11).

To engage the chain brake manually, simply push the hand

guard (I/11) forward (towards the tip of the saw) with your left

hand (arrow 1).

Releasing the chain brake

Pull the hand guard (I/11) towards you (arrow 2) until you feel

it catch. The brake is now released.

Note:

When the chain brake is actuated the power supply to the motor

will be cut off. Testing of the chain brake is described on page

12.

I

Chain brake maintenance

The chain brake is a very important safety feature, and like

any other part it is subject to a certain amount of wear.

Regular inspection and maintenance is important for your

personal safety, and can be properly performed only by a

MAKITA service center.

SERVICE