14

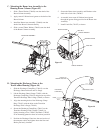

D. Heavy-Duty Air Cleaner

1. Every 250 hours of operation (more often under

extremely dusty or dirty conditions), replace the main

paper element and check inner element. Follow

these steps.

a) Unhook the two retaining clips and remove the

end cap from the air cleaner housing.

b) Pull the air cleaner element out of the housing.

See Removing Elements Figure.

c) After the main element is removed, check the

condition of the inner element. It should be

replaced whenever it appears dirty, typically

every other time the main element is replaced.

Clean the area around the base of the inner

element before removing it, so dirt does not get

into the engine.

d) Do not wash the paper element and inner

element or use pressurized air, this will damage

the elements. Replace dirty, bent or damaged

elements with new genuine Kohler elements as

required. Handle new elements carefully; do not

use if the sealing surfaces are bent or damaged.

e) Check all parts for wear, cracks or damage.

Replace any damaged components.

f) Install the new inner element, Kohler Part No.

25 083 04-S followed by the outer element,

Kohler Part No. 25 083 01-S. Slide each fully

into place in the air cleaner housing.

g) Reinstall the end cap so the dust ejector valve is

down and secure with the two retaining clips.

See Heavy-Duty Air Cleaner Assembly

Figure.

E. Spark Plug

1. Every 200 hours of operation, remove the spark

plugs, check condition, and reset the gap or replace

with new plugs as necessary. The standard spark

plug is a Champion@ RC12YC (Kohler Part No.

12 132 02-S). A high-performance spark plug,

Champion@ Premium Gold 2071 (used on Pro

Series engines, Kohler Part No. 12 132 06-S) is also

available. Equivalent alternate brand plugs can also

be used.

a) Before removing the spark plug, clean the area

around the base of the plug to keep dirt and

debris out of the engine.

b) Remove the plug and check its condition.

Replace the plug if worn or reuse is

questionable. NOTE: Do not clean the spark

plug in a machine using abrasive grit. Some grit

could remain in the spark plug and enter the

engine causing extensive wear and damage.

c) Check the gap using a wire feeler gauge. Adjust

the gap to 0,76 mm (0.030 in,) by carefully

bending the ground electrode.

d) Reinstall the spark plug into the cylinder head.

Torque the spark plug to 24.4-29J N-m

(18-22 ft. lb,). 4. Reinstall the spark plug into

the cylinder head. Torque the spark plug to

24.4-29J N-m(18-22 ft. lb,).

Removing Elements Figure

Heavy-Duty Air Cleaner

Assembly Figure