10

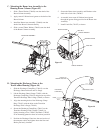

a) Turn off the engine and wait until all moving

parts have come to a complete stop.

b) Disconnect the spark plug wires from the spark

plugs on the engine.

c) Remove the Hose Assembly from the Inlet

Flange Assembly. With this removed, open the

Inlet Flapper and remove any debris that is

clogging the housing. CAUTION SHOULD BE

USED WHEN CLEARING DEBRIS FROM

INSIDE THE HOUSING. GLOVES SHOULD

BE WORN AS SHARP EDGES ON THE FAN,

THE TALON RING, OR IN THE DEBRIS

MAY BE PRESENT.

d) Remove the Discharge Chute from the

Transition Discharge Tube’s flange. With the

Chute removed, inspect the Transition

Discharge part of the housing and remove any

debris clogging this area. CAUTION SHOULD

BE USED WHEN CLEARING DEBRIS

FROM INSIDE THE HOUSING. GLOVES

SHOULD BE WORN AS SHARP EDGES ON

THE FAN, THE TALON RING, OR IN THE

DEBRIS MAY BE PRESENT.

e) Inspect the Discharge Chute for debris and

remove any debris clogging this area.

f) In order to re-assemble the removed parts,

please refer to the Assembly Instructions

found in this manual. After the unit is

re-assembled, reconnect the spark plug wires

and resume operation.

E. Re-filling the Gas Tank

1. If the unit was being operated, make sure the

engine has been turned “off” and is allowed to cool

off completely.

2. Once you have determined the engine is cool, fill the

tank with the proper fuel. Take extra caution when

filling the tank not to over-fill it. The fuel

recommendations are found in the Engine Oil and

Fuel section of this manual.

Transportation:

A. Preparing the TruckLoader Unit for

Transportation

1. Make sure the engine is off.

2. Disconnect the Carabiner (720487) from the hose band.

3. Attach the Carabiner to the chain link closest to the

Boom Arm Assembly.

4. Rotate the Boom Arm Assembly toward the vehicle to

allow the locking bosses on the Arm and Column to

line up. Once the bosses are aligned, insert the Linch

Pin (720437) through the hole and snap the ring over

the boss to secure.

5. Make sure the Chain Loop Assembly cannot make

contact with anything other than the Boom Arm

Assembly. If necessary, use a bungee cord to secure it.

6. Remove the Hose Assembly from the Inlet Flange

Assembly.

7. Close the Inlet Flapper and rotate the Flapper Retainer

(720257) to allow the Flapper to be secured by

tightening the knob.

8. Remove the Discharge Nozzle from the

TruckLoader Housing.

9. Secure all the removed TruckLoader parts in the bed

of the vehicle with the proper rope or hardware.

10. Before moving a trailer containing the TruckLoader

unit, be sure that everything is properly secured for

road travel and that safety towing chains are properly

attached to the vehicle.

Engine Oil and Fuel:

A. Oil Recommendations: using the proper type and

weight of oil in the crankcase is extremely important.

It is also important to check oil daily and change oil

regularly. Failure to use the correct oil, or using dirty

oil, causes premature engine wear and failure.

1. Oil Type: Use high quality detergent oil of API

(American Petroleum Institute) service class

SC; SH, SJ or higher. Select the viscosity based

on the air temperature at the time of operation

as shown in the following table.

NOTE: Using other than service class SG, SH, SJ or higher oil

or extending oil change intervals longer than recommended can

cause engine damage. A logo or symbol on oil containers

identifies the API service class and SAE viscosity grade.

B. Fuel Recommendations:

1. Fuel Type: For best results use only clean,

fresh, unleaded gasoline with a pump sticker

octane rating of 87 or higher. In countries using

the Research method, it should be 90-octane

minimum. Unleaded gasoline is recommended

as it leaves less combustion chamber deposits

and reduces harmful exhaust emissions.