28

Section 6: Maintenance & Lubrication

SB1051, SB1064, SB1574, & SB2584 with S/N 881640- Snow Blowers 370-027M

10/08/14

Table of Contents

General Maintenance Information

Proper servicing and adjustment is the key to the long life

of any implement. With careful inspection and routine

maintenance, you can avoid costly downtime and repair.

Check all bolts after using unit for several hours to be

sure

they are tight. Replace any worn, damaged, or

illegible safety labels by obtaining new labels from your

Land Pride dealer.

The parts on your Snow Blower have been specially

designed and should only be replaced with genuine Land

Pride parts. Do not alter the Snow Blower in a way which

will adversely affect its performance.

Tractor Maintenance

One of the most important things you can do to prevent

hydraulic system problems is ensure that your tractor's

reservoir remains free of dirt and contamination.

Use a clean cloth to wipe hose ends before attaching

them to your tractor. Replace your tractor’shydraulicfilter

element at the prescribed intervals. These simple

maintenances will go a long way to prevent occurrence of

control valve and hydraulic cylinder problems.

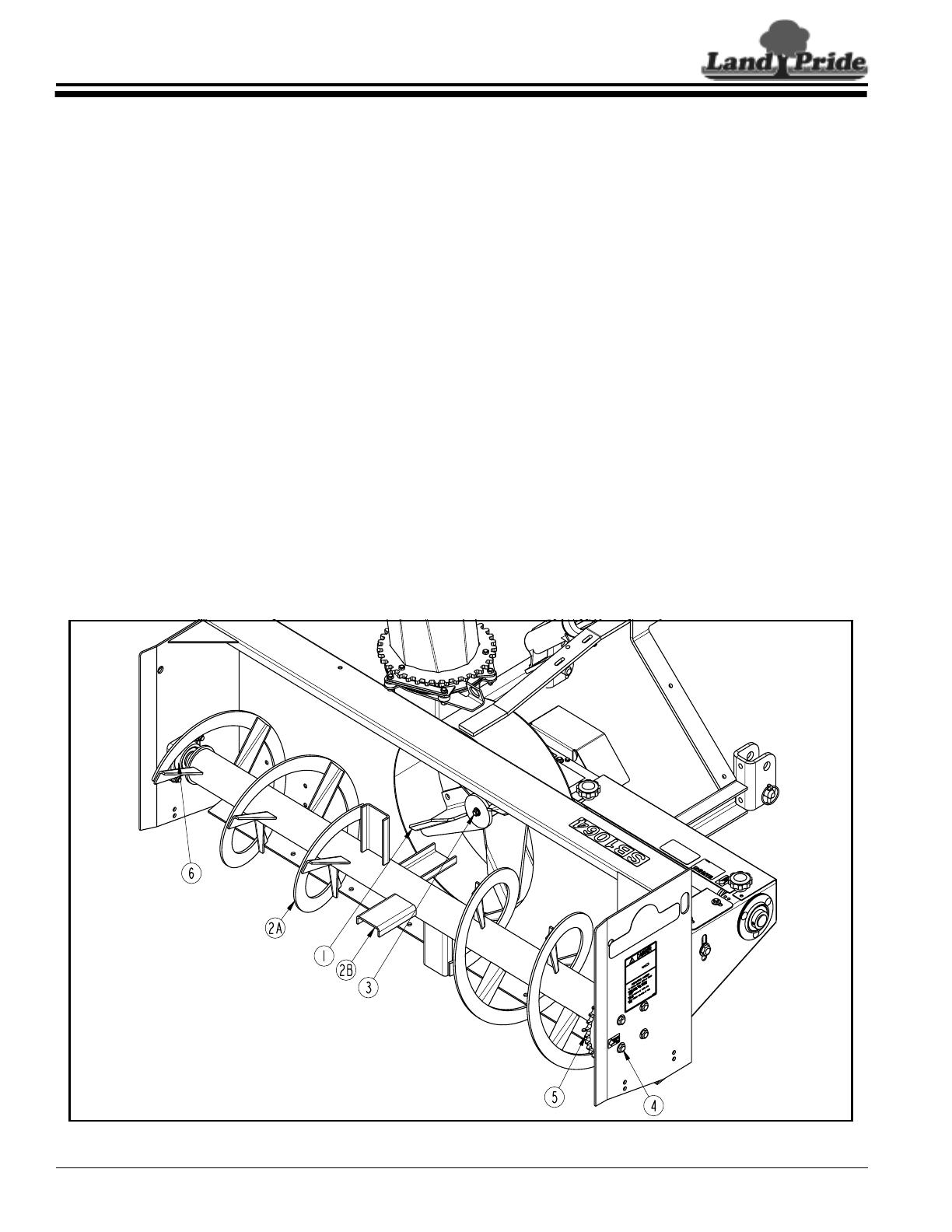

Auger & Impeller Inspection

Refer to Figure 6-1:

1. Check 3/8"-16 GR5 Impeller bolt (#3) for tightness,

Make certain it is torqued tight.

2. Check impellers (#1) for wear, structural cracks, and

breakage. Repair or replace impeller before it

causes structural damage to Snow Blower housing.

3. Check forbent impellers (#1) that are making contact

or are about to make contact with Snow Blower

housing. Repair or replace impeller before it causes

structural damage to Snow Blower housing.

4. Check augerflighting (#2A) and auger paddles (#2B)

for wear, structural cracks, bending, and breakage.

Repair or replace auger before components break-

off and are sent into the impeller or through the air.

5. Check end bearings (#6) for wear. Replace bearings

that are worn excessively.

6. Lubricate bearings as required. See lubrication

schedule for “Auger Flange Bearings” on page 33.

7. Check bearing mounting bolts (#4) for tightness.

Make certain they are tightened to the correct torque.

8. Check roller chain and sprocket (#5) for wear and

chain tightness. Replace chain and/or sprocket if

they are worn excessively. See “Roller Chain Take-

up” instructions on page 22.

Section 6: Maintenance & Lubrication

Auger & Impeller Inspection

Figure 6-1

33295