18

RTA10 & RTA15 Series Rotary Tillers 311-252M

5/05/06

Land Pride

Section 4 Maintenance and Lubrication

Table of Contents

4. Inspect the clutch and ensure that the scribed

markings made on the clutch plates have changed

position. Slippage has not occurred if any two marks

on the friction disk and plate are still aligned. A clutch

that has not slipped must be disassembled to

separate the friction disk plates. See Clutch

Disassembly & Reassembly on page 19.

Refer to Figure 4-3 (View - B):

5. Turn all 4 nuts fully back if no two marks on the friction

disk and plate are still aligned. Clutch is ready for use.

6. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

Clutch Run-In With 8- Hex Head Socket Bolts

Figure 4-2

Clutch Run-In With 4 Tightening Nuts

Figure 4-3

Clutch Disassembly & Reassembly

Clutches With 8-Hex Head Socket Bolts

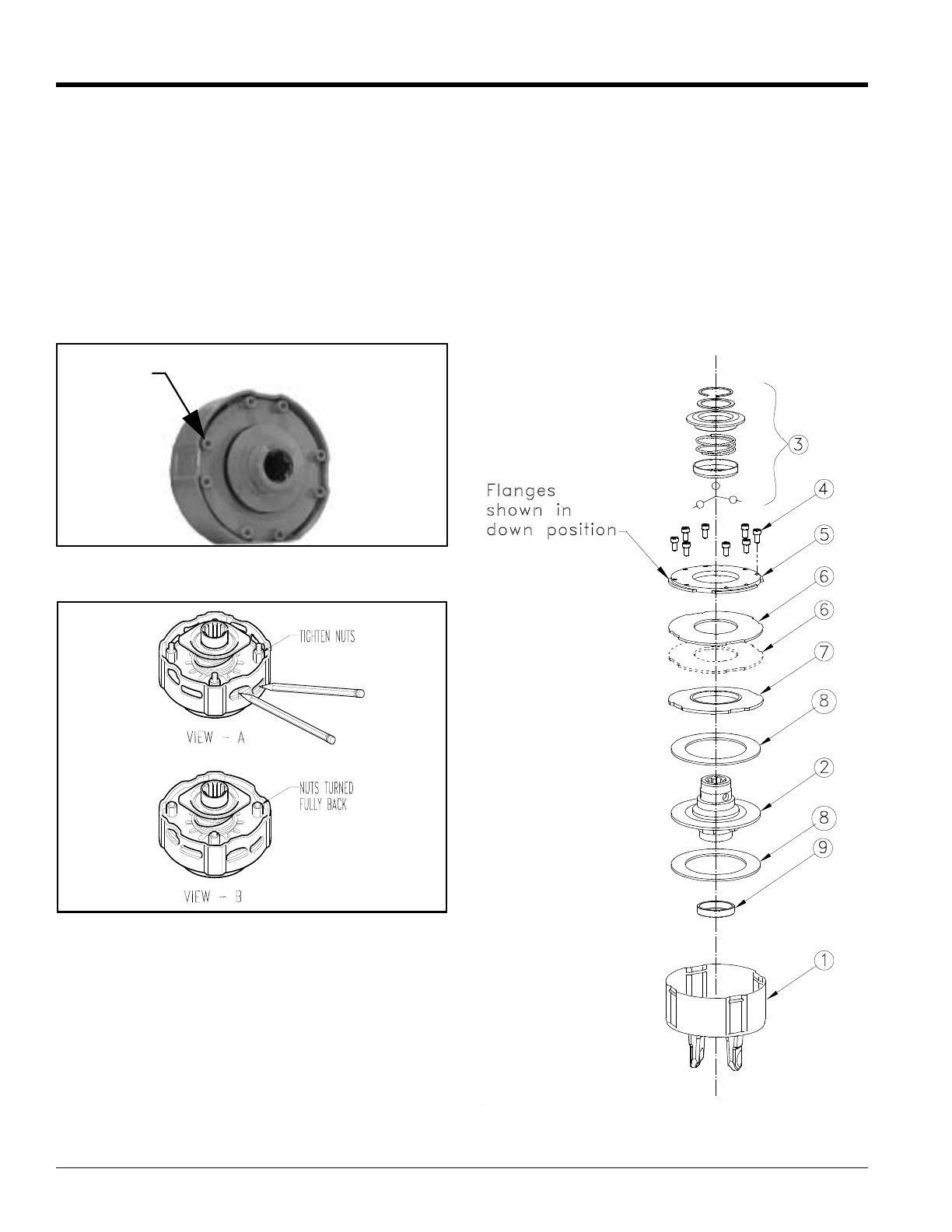

Refer to Figure 4-4

If the clutch run-in procedure, see Clutches With 8-Hex

Head Socket Bolts, indicated that one or more of the friction

disks did not slip, then the clutch must be disassembled to

separate the friction disks.

1. Rotate 8 hex head socket bolts (#4) all the way out to

free stop flange (#5).

2. Rotate stop flange (#5) and remove from housing (#1)

3. Remove the following inner components:

a. Spring kit (#6)

b. Pressure flange (#7)

c. 1st Friction Disc (#8)

d. Hub with flange and pull collar (#2 & #3)

e. 2nd Friction disc (#8)

f. Bearing (#9)

4. Inspect all components and replace to their original

position. Make certain stop flange (#5) is replaced

with its flanges down as shown.

5. Fully tighten all 8 hex head socket bolts (#4).

Clutch Assembly

Figure 4-4

Hex Head

Socket Bolts

21270

22171

21302