17

Section 5 Maintenance and Lubrication

7/14/08

RC45180 & RCM45180 Rotary Cutter 312-382M

Land Pride

Table of Contents

Section 5 Maintenance and Lubrication

Maintenance

Proper servicing and adjustment is the key to the long life

of any farm implement. With careful and systematic in-

spection, you can avoid costly maintenance, time and re-

pair.

For safety reasons, each maintenance operation must be

performed wiht tractor PTO disengaged, the cutter low-

ered completely to the ground or on safely supported

blocking, tractor engine shut off and ignition key removed.

1. After using your cutter for several hours, check all

bolts to be sure they are tight.

2. After transporting your cutter for several hours, check

all wheel lugs, bolts and nuts to be sure they are tight.

Always maintain proper air pressure in the tires.

Service Cutting Blades

1. Both blades on each dishpan should be sharpened at

the same angle as the original cutting edge and must

be replaced or reground at the same time to maintain

proper balance in the cutting unit.

IMPORTANT: Replace blades with genuine Land Pride

blades only. If one blade is to be replaced, the mating

blade {on the same carrier} must also be replaced.

2. Both blades on each dishpan should weigh the same af-

ter sharpening.

3. When replacing or sharpening the cutter blades, exam-

ine bolts and hardware for excessive wear and replace if

necessary.

a. Torque blade bolt lock nut to 450 ft. pounds. An ex-

tended cheater bar may be required to achieve

proper torque.

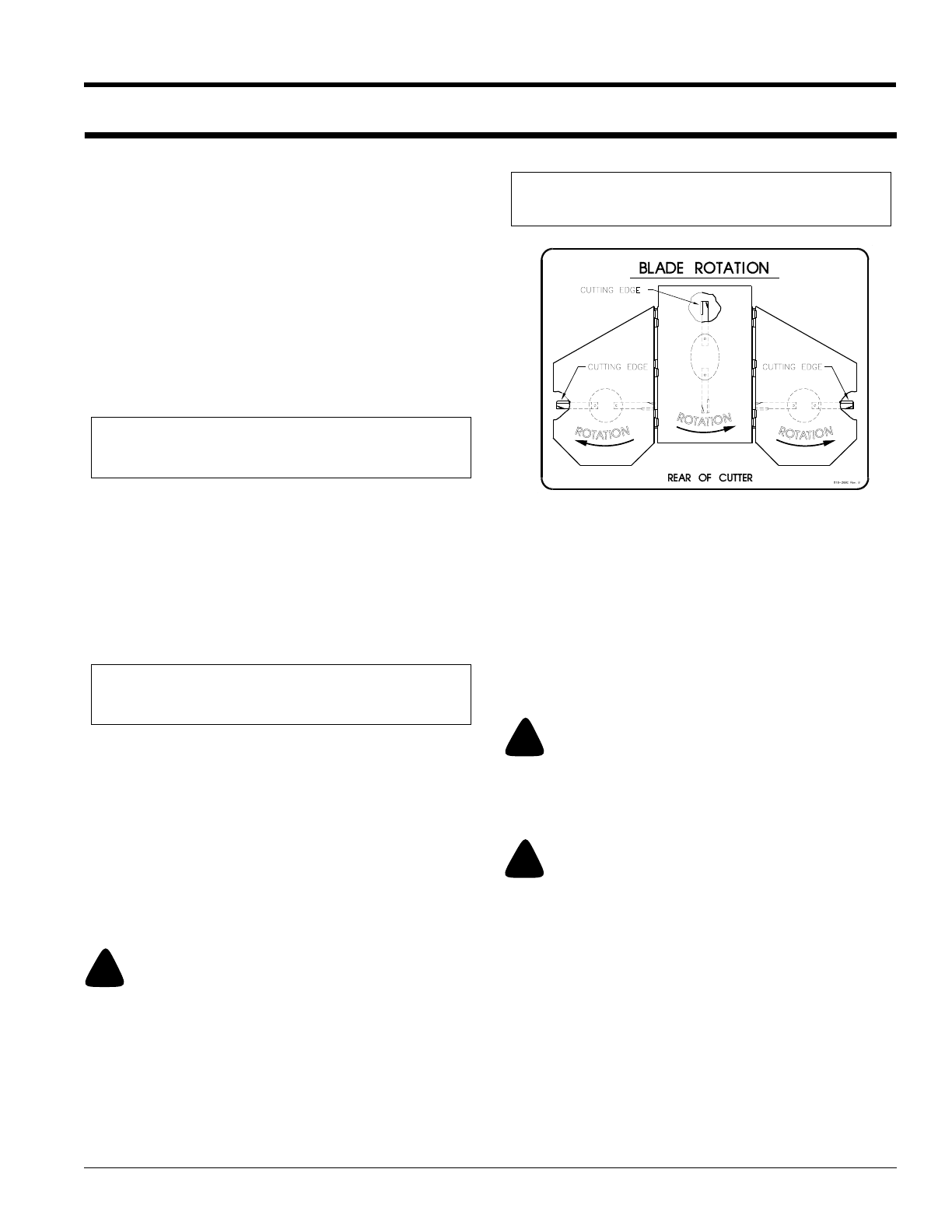

b. Carefully check the cutting edges of the blades in re-

lation to the blade carrier rotation diagram below to

ensure correct blade placement.

!

CAUTION!

Installation of the longer blades on the wing decks will cause an

immediate operating hazard.

NOTE: Check tightness of bolts periodically, using

the “Torque Values Chart” on 24 as a guide.

NOTE: Do not remove any more material than nec-

essary when sharpening blades.

4. Blade Dishpan Replacement:

Dishpan nut on gearbox output shafts should be torqued

to 450 foot/pounds and cotter pin installed in nut with legs

securely bent around nut.

Skid Shoe Service & Replacement

The center deck skid shoes should be checked periodical-

ly for wear and replaced is necessary. Order center deck

skid shoe Land Pride part #312-218H. No adjustment is

required.

!

CAUTION!

Skid shoe replacement must be done with the deck raised to the

transport position and securely blocked. Engage parking brake,

shut off tractor, remove key and disengage PTO before adjusting

or replacing these parts.

!

WARNING!

Excessive wear on skids may cause inadequate operation of cut-

ter and create a safety hazard!

The wing deck skid shoes should be checked periodically

for wear. Excessive leading edge wear can be repaired by

interchanging the LH wing skid with the RH wing skid. If

both leading edges have been worn down, order skid shoe

Land Pride part # 312-446H.

Skid Shoes

To replace center deck skid shoes:

Refer to Figure 5-2:

a. Attach skid shoe to cutter, using four 1/2" bolts

lock washers and hex nuts.

b. Repeat for opposite skid shoe.

NOTE: Blades for the wings & center deck are 25"

long, Note rotation as shown in Figure 5-1.

818-268C

Blade Rotation

Figure 5-1