8

Section 1 Assembly and Setup

RC45180 & RCM45180 Rotary Cutter 312-382M 7/14/08

Land Pride

Table of Contents

Section 1 Assembly and Setup

Tractor Requirements

This cutter is designed for tractors with a minimum PTO

horsepower rating of 50 HP and maximum of 150 HP.

!

CAUTION!

Do not over speed PTO or machine damage may result. This

cutter is designed to be used with a tractor using a 540 or

1,000 rpm rear PTO but not both.

Specifically, each cutter is equipped for only one mode of

operation. Do not attempt to operate a 540 PTO cutter

with a 1,000 RPM PTO tractor. Do not operate a 1000

RPM PTO cutter with a 540 PTO tractor. Note that many

tractors provide both 540 and 1,000 RPM PTO modes.

Check your tractors manual to determine your exact con-

figuration.

Before You Start

Read and understand the owners manual for your cutter. A

basic understanding of how it works will aid in the assem-

bly and setup of your cutter.

Before attempting to assemble the cutter use the following

as a check list. Having all the needed parts and equipment

readily at hand will speed up your assembly task and will

make the job as safe as possible.

❑ Check for fasteners and pins that were shipped with the

cutter. Note: All hardware coming from the factory has

been installed in the location where it will be used. If a part

or fastener is temporarily removed for assembly reasons,

remember where it goes. Keep the parts separated.

❑ If a pin, bolt or other part has been removed, and you

are unsure where it is used, use the parts section to iden-

tify it. Be sure the part gets used in the correct location. By

double checking while you assemble, you will decrease

the chance of using a bolt incorrectly that may be needed

later.

❑ Have a fork lift or loader along with chains and safety

stands that are sized for the job ready for the assembly

task.

❑ Have a minimum of 2 people at hand while assembling

the cutter.

❑ Check to see all nuts are tightened. See “Torque Val-

ues Chart” page 24 for additional torque specifications.

Dealer Cutter

Assembly & Preparations

This cutter has been partially assembled at the factory.

The hitch & both wing axles will need to be assembled.

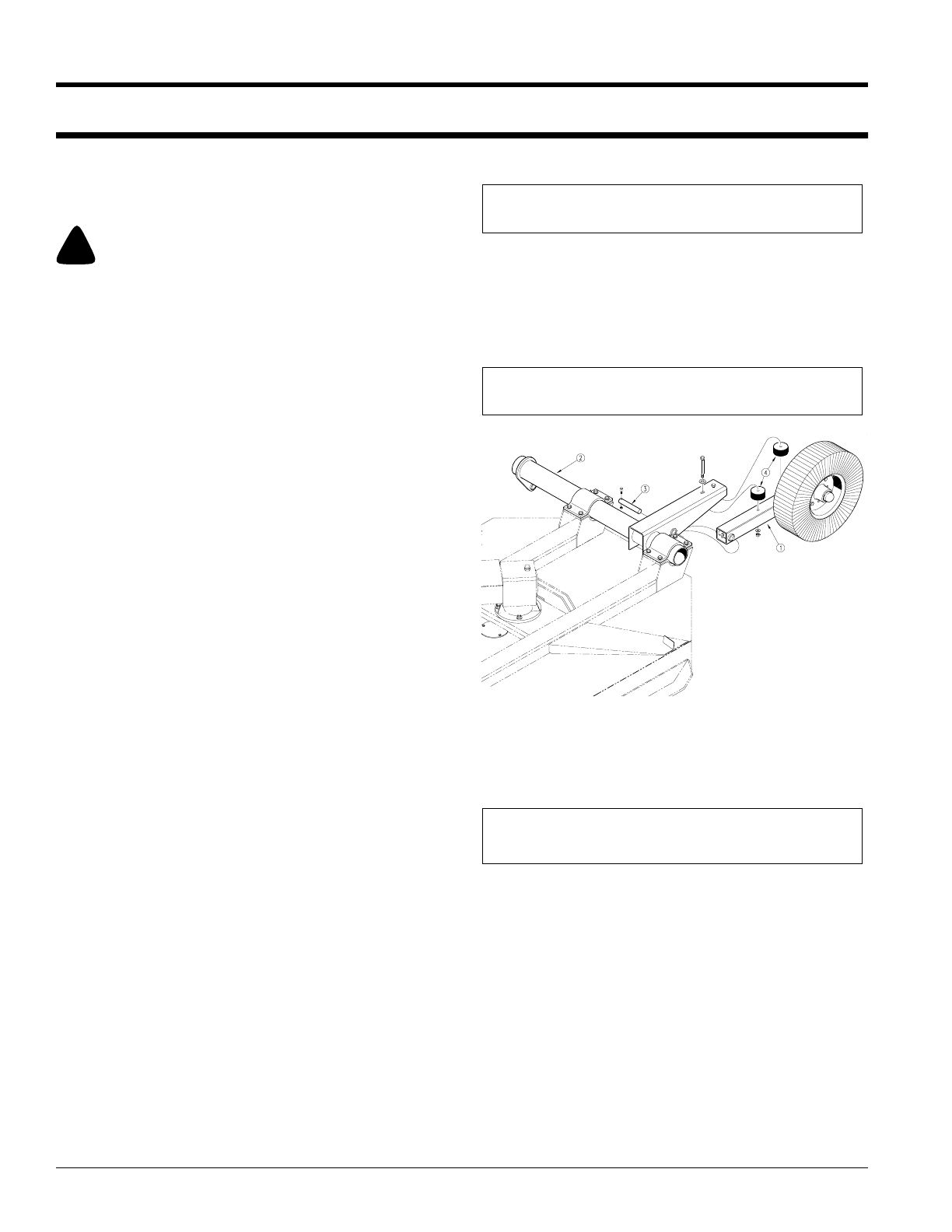

Left & Right Wing Axle Assembly

Refer to Figure 1-1:

1. Assemble axle tube arm assembly (#1) with tire to

wing axle (#2), using axle mount pin (#3) with hard-

ware. Install rubber bumpers (#4) with hardware.

2. Grease points marked by arrows as noted in "Main

tenance & Lubrication" section page 19.

Hitch Assembly

Refer to Figure 1-2:

1. Insert main hitch rear mount bushings (#2) into hitch

pivot. Install the main hitch (#1) to the forward hitch

plates. Secure with 1" x 8" hex bolt (#3) and 1" flat

washers and Nylock nut. Nut should be located to-

ward the inside as shown.

2. Install both leveling rods (#4) through the respective

trunnion pivot of the hitch. Secure the leveling rod to

the hitch with the leveling tube weldment (#6) and a 7/

8" hex nut (#8). Note: The leveling tube weldment

should be screwed onto the leveling rod about 3" as a

preliminary adjustment. Final adjustment should not

be made until the cutter is attached to the tractor.

NOTE: Hardware bag should be banded to unit.

NOTE: Make sure nuts & bolts are tight.

Wing Axle Assembly

Figure 1-1

13869

NOTE: Do not tighten hardware until assembly is

complete.