TP-6804 12/11 65Section 5 Scheduled Maintenance

5.7 Battery

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Battery electrolyte is a diluted sulfuric acid. Battery acid

can cause severe injury or death. Battery acid can cause

blindness and burn skin. Always wear splashproof safety

goggles, rubber gloves, and boots when servicing the battery.

Do not open a sealed battery or mutilate the battery case. If

battery acid splashes in the eyes or on the skin, immediately

flush the affected area for 15 minutes with large quantities of

clean water. Seek immediate medical aid in the case of eye

contact. Never add acid to a batteryafter placing the battery in

service, as this may result in hazardous spattering of battery

acid.

Battery acid cleanup. Battery acid can cause severe

injury or death. Battery acid is electrically conductive and

corrosive. Add 500 g (1 lb.) of bicarbonate of soda (baking

soda) to a container with 4 L (1 gal.) of water and mix the

neutralizing solution. Pour the neutralizing solution on the

spilled battery acid and continue to add the neutralizing

solution to the spilled battery acid until all evidence of a

chemical reaction (foaming) has ceased. Flush the resulting

liquid with water and dry the area.

Battery gases. Explosion can cause severe injury or

death. Battery gases can cause an explosion. Do not smoke

or permit flames or sparks to occur near a battery at any time,

particularly when it ischarging. Do not dispose of a batteryin a

fire. To prevent burns and sparks that could cause an

explosion, avoid touching the battery terminals with tools or

other metal objects. Remove all jewelry before servicing the

equipment. Discharge static electricity from your body before

touching batteries by first touching a grounded metal surface

away from the battery. To avoid sparks, do not disturb the

battery charger connections while the battery is charging.

Always turn the battery charger off before disconnecting the

battery connections. Ventilate the compartments containing

batteries to prevent accumulation of explosive gases.

Battery short circuits. Explosion can cause severe injury

or death. Short circuits can cause bodily injury and/or

equipment damage. Disconnect the battery before generator

set installation or maintenance. Remove all jewelry before

servicing the equipment. Use tools with insulated handles.

Remove the negative (--) lead first when disconnecting the

battery. Reconnect the negative (--) lead last when

reconnecting the battery. Never connect the negative (--)

battery cable to the positive (+) connection terminal of the

starter solenoid. Do not test the battery condition by shorting

the terminals together.

Refer to this section for general battery information and

maintenance. Also consult the battery manufacturer’s

instructions for battery maintenance.

All generator set models use a negative ground with a

12-volt engine electrical system. Consult the generator

set nameplate for the engine electrical system voltage.

Consult the generator spec sheet for battery capacity

recommendations for replacement purposes. Wiring

diagrams provide battery connection information. See

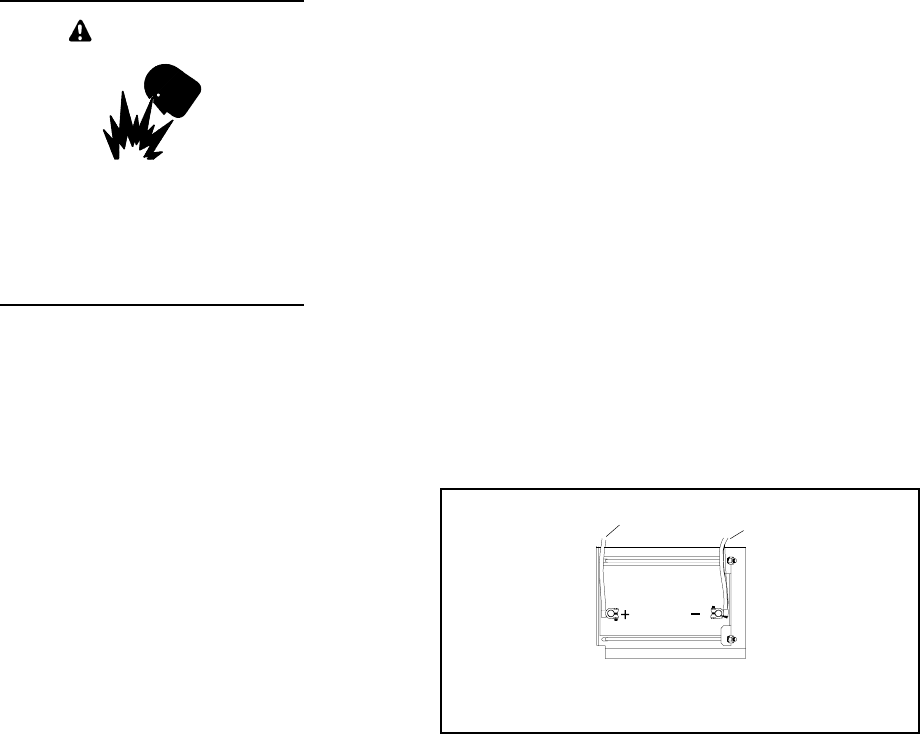

Figure 5-9 for typical battery connections.

EZ-273000-J

1

2

1. To positive (+) terminal on starter solenoid.

2. To ground (--) terminal on or near starter motor.

Figure 5-9 12-Volt Engine Electrical System Single

Starter Motor, Typical Battery Connection

Clean the battery and cables and tighten battery

terminals using the service schedule recommendations.

To prevent corrosion, maintain tight, dry electrical

connections at the battery terminals. To remove

corrosion from battery terminals, disconnect the cables

from the battery and scrub the terminals with a wire

brush. Clean the battery and cables with a solution of

baking soda and water. After cleaning, flush the battery

and cables with clean water and wipe them with a dry,

lint-free cloth.

After reconnecting the battery cables, coat the battery

terminals with petroleum jelly, silicone grease, or other

nonconductive grease.