7

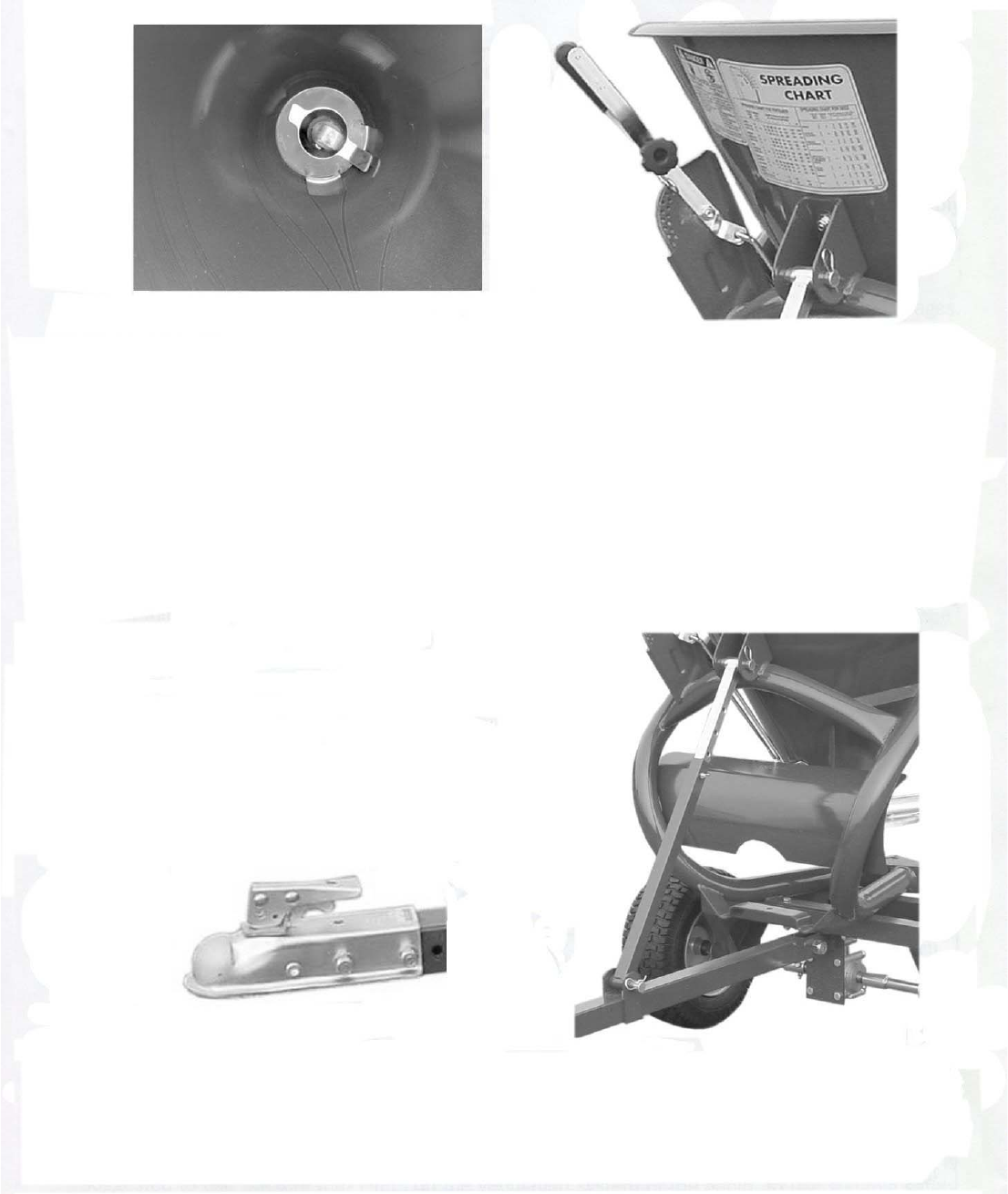

The feeding of the disc is by gravity through an opening located at the bottom of

the hopper, inside of which a mix/agitator is applied, in order to prevent forma-

tion of lumps in the fertilizer. A plate is put in front of the disc to prevent the

speading to the front side of the machine.

The fertilizer delivery is controled by properly opening the shutters in the hopper

bottom, through locking devices operated by levers. The fertilzer spreader and

the agitator are connected through a gearbox with the wheels, so the speed of

the disc is proportionate to the speed of the machine. The switching off and on

of the spreading disc is made by putting or removing the split pin on the axle.

The machine is connected with a ball hitch 1-7/8”.

There is an adjustable tongue so the height

can be adjusted to keep the spreader parallel

with the ground.

The hardness of the steel welded frame, together with the remarkable life of the

hopper, helps to obtain a highest quality level of the pull type spreaders. The

painting is made by an epoxy varnish with successive backing at 150 degrees

celsius with the application of the primer bath, assuring great protection and long

life of the machine.