18 – English

ASSEMBLY

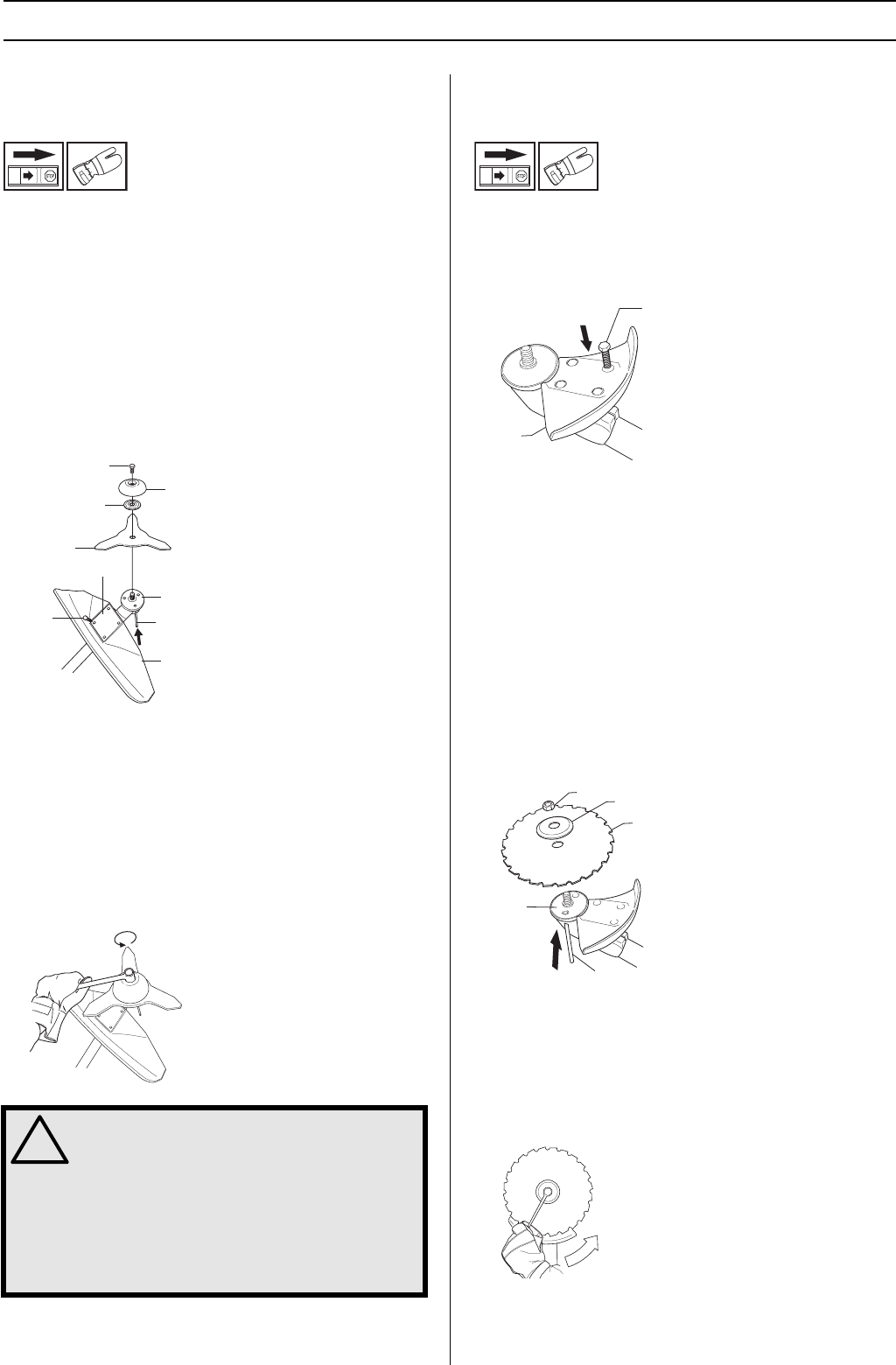

Fitting a blade guard, grass blade

and grass cutter

• The blade guard (A) is fitted using 4 screws (L) and the

support plate (M) as shown.

CAUTION! Always use the recommended guard for the

cutting attachment you are using. See chapter on

Technical data.

• Fit the drive disc (B) on the output shaft.

• Turn the blade shaft until one of the holes in the drive disc

aligns with the corresponding hole in the gear housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• Place the blade (D) on the output shaft.

• Fit the support flange (F) on the output shaft. Make sure

that the blade is centered by fitting it to the guide on the

support flange.

• Screw the support cup (E) onto the output shaft threads

(CAUTION! Left-hand thread). Tighten to a torque of 35-

50 Nm (3.5-5.0 kpm). Use the socket spanner in the tool

kit. Note that the locking pin (C) must remain inside the

gear housing to lock the drive disk. Hold the shaft of the

socket spanner as close to the blade guard/combination

guard as possible.

Fitting the blade guard and saw

blade

• The blade guard (A) is fitted using 4 screws (L) as shown.

CAUTION!

Always use the recommended guard for the cutting

attachment you are using. See chapter on Technical data.

• Fit the drive disc (B) on the output shaft.

• Turn the blade shaft until one of the holes in the drive disc

aligns with the corresponding hole in the gear housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• Place the blade (D) and support flange (F) on the output

shaft.

• Fit the nut (G). The nut must be tightened to a torque of

35-50 Nm (3.5-5 kpm). Use the socket spanner in the tool

kit. Hold the shaft of the spanner as close to the blade

guard as possible.

To tighten the nut, turn the spanner in the opposite

direction to the direction of rotation (Caution! left-hand

thread).

When loosening and tightening the saw blade nut, there is a

risk of injury from the teeth of the saw blade. You should

therefore always ensure that your hand is shielded by the

blade guard when doing this. Always use a socket spanner

with a shaft that is long enough to allow this. The arrow in the

diagram shows the area where you should operate the socket

spanner when loosening or tightening the nut.

!

WARNING! Tighten the lock screw (N) in the

center hole of the support cup. Tighten to a

torque of 35-50 Nm (3.5-5.0 kpm), CAUTION!

Left-hand thread. If the lock screw is not

fitted in the support cup, there is a risk that

the support cup will come unscrewed. This

means that the blade will also come loose,

which could result in serious or fatal injury

to the operator or others.

M

E

N

F

D

B

C

A

L

L

A

G

F

D

B

C