English – 31

MAINTENANCE

High speed jet H

At the factory the engine is adjusted at sea level. When

working at a high altitude or in different weather

conditions, temperatures and atmospheric humidity, it

may be necessary to make minor adjustments to the high

speed jet.

CAUTION! If the high speed jet is screwed in too far, it

may damage the piston/cylinder.

When test run at the factory, the high speed jet is set so that

the engine satisfies the applicable legal requirements at the

same time as achieving maximum performance. The

carburetor’s high speed jet is then locked using a limiter cap

in the fully screwed out position. The limiter cap limits the

potential to adjust the high speed jet to at most half a turn.

CAUTION! There is an integrated speed governor in the

ignition system that limits the maximum speed to 13000 rpm.

The maximum speed will not exceed 13000 rpm when the

high speed jet is adjusted (screwed in). When the speed

governor is activated, you will get the same sound experience

as when the chain saw 4-cycles.

To adjust the carburetor correctly you should contact a

mechanic with access to a rev counter.

CAUTION! As the spark is cut off, the rev counter does not

show speeds higher than 13000 rpm.

Correctly adjusted carburetor

When the carburetor is correctly adjusted the machine

accelerates without hesitation and the machine 4-cycles a

little at max. speed. It is also important that the chain does not

rotate at idle. If the L-jet is set too lean it may cause starting

difficulties and poor acceleration. If the H-jet is set too lean

the machine will have less power, poor acceleration and could

suffer damage to the engine.

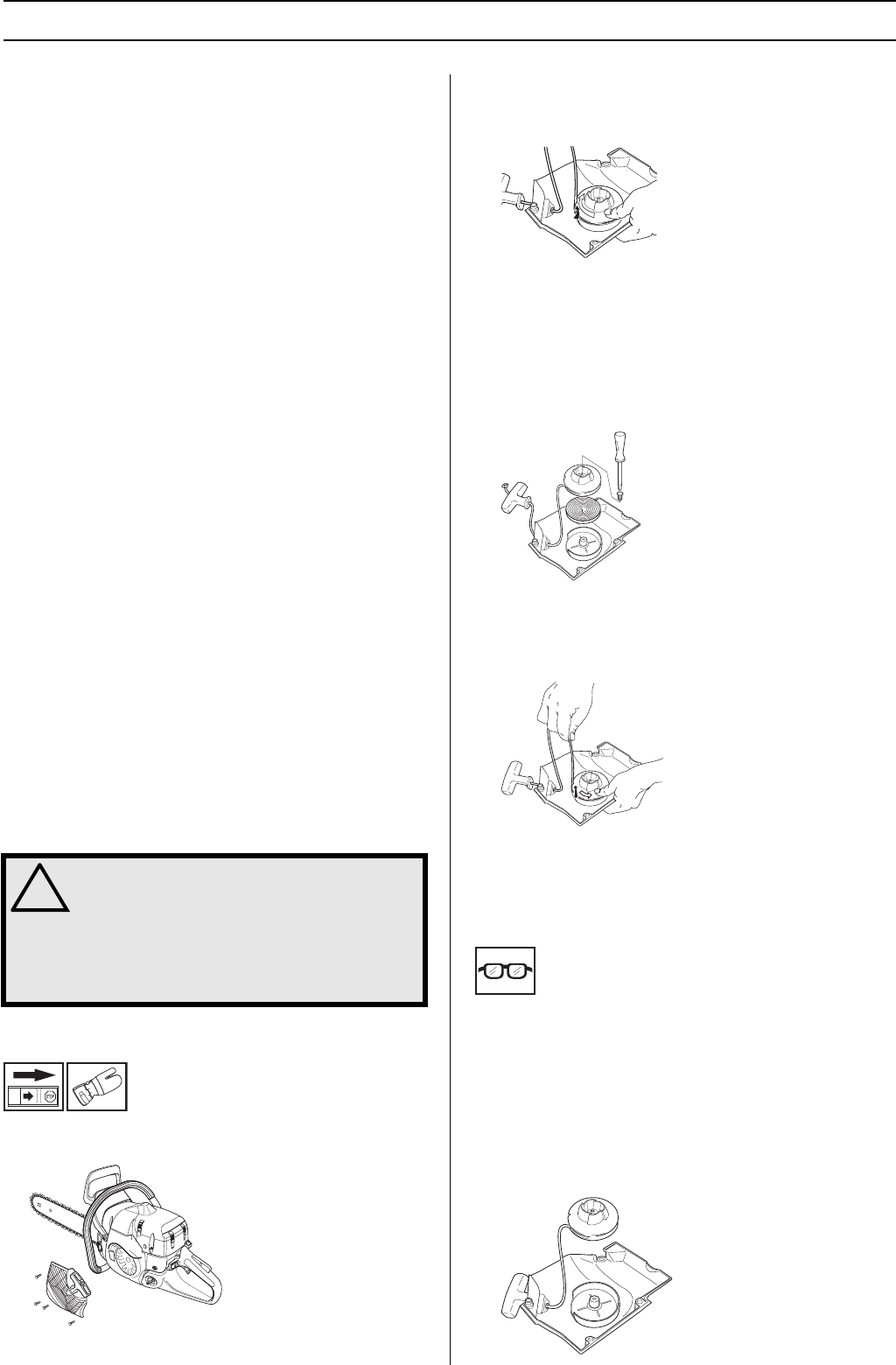

Starter

Changing a broken or worn starter cord

• Loosen the screws that hold the starter against the

crankcase and remove the starter.

• Pull out the cord approx. 30 cm (12 inches) and hook it

into the notch in the rim of the pulley. Release the recoil

spring by letting the pulley rotate slowly backwards.

• Undo the screw in the centre of the pulley and remove the

pulley. Insert and fasten a new starter cord to the pulley.

Wind approx. 3 turns of the starter cord onto the pulley.

Connect the pulley to the recoil spring so that the end of

the spring engages in the pulley. Fit the screw in the

center of the pulley. Insert the starter cord through the

hole in the starter housing and the starter handle. Make a

secure knot in the end of the starter cord.

Tensioning the recoil spring

• Hook the starter cord in the notch in the pulley and turn

the starter pulley about 2 turns clockwise.

CAUTION! Check that the pulley can be turned an

additional 1/2 turn when the starter cord is pulled all the

way out.

Changing a broken recoil spring

• Lift off the pulley. See instructions under heading

Changing a broken or worn starter cord.

• Remove the recoil spring from inside the pulley by tapping

the pulley lightly with its inside face downwards against a

work bench or the like. If the spring pops out during fitting,

wind it up again, working from the outside in towards

centre.

• Lubricate the recoil spring with light oil. Fit the pulley and

tension the recoil spring.

!

WARNING! When the recoil spring is wound

up in the starter housing it is under tension

and can, if handled carelessly, pop out and

cause personal injury. Always be careful

when changing the recoil spring or the

starter cord. Always wear protective

goggles.