14.Never replace hex bolts with less than grade five bolts unless otherwise specified,

i.e. shear bolts

9

.

15.Where replacement parts are necessary for periodic maintenance and servicing,

genuine replacement parts must be used to restore your equipment to original

specifications. The company will not claim responsibility for use of unapproved parts

and/or accessories and other damages as a result of their use.

16.Unauthorized modifications to the machine may impair the function and/or safety of

the machine and reduce its life. If equipment has been altered in any way from

original design, the manufacturer does not accept any liability for injury or warranty.

4.02 - Service

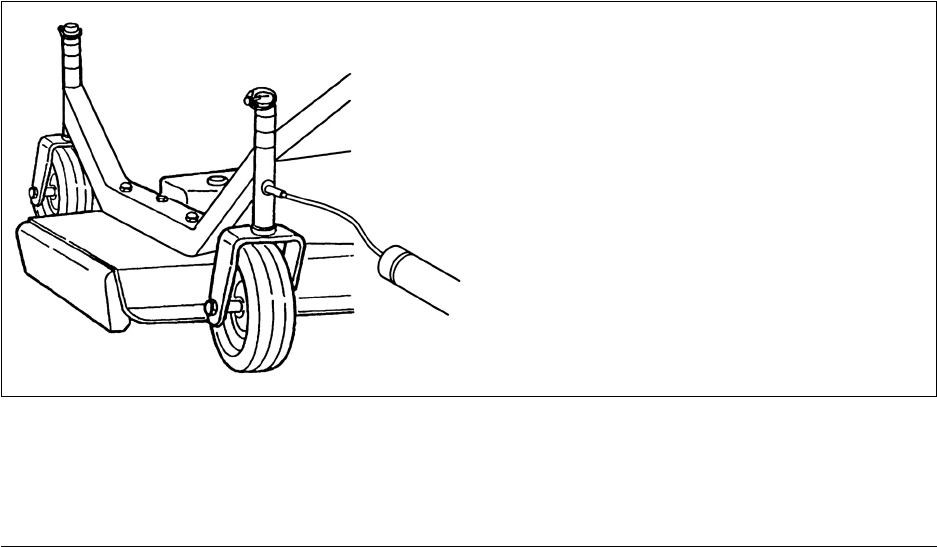

The accompanying illustrations show lubrication points. The chart gives the frequency of

lubrication in hours, based on normal operating conditions. Severe or unusual

conditions may require more frequent lubrication.

Use a good quality SAE multipurpose type grease for all locations shown. Be sure to

clean fittings thoroughly before using grease gun.

Use 90 wt. gear oil in gearbox.

Hourly:

1. Check the condition of mower blades for nicks or dull edges. Sharpen if necessary.

2. Replace bent or damaged blades

10

.

3. Also check blades for damage after hitting an obstruction.

4. Clean foreign material from mower deck and belt area.

Every 8 hours:

1. Lubricate the driveline and the wheel yokes: Apply two or three shots of grease

to the driveline cross and bearings and the telescoping shafts; apply the same

MAINTENANCE 25 FRONTIER

G

ROOMING MOWERS OPERATOR’S MANUAL

10

See Section 4.03 - Blade Maintenance.

9

Refer to Table 1 - Torque Specifications, page 32.

Fig. 10

Wheel yokes lubrication.