Assembly

1. Finish removing the crate from around the

machine.

2. Remove the bolts holding the machineto the

skid.

3. Carefully clean all rust protected surfaceswith a

mild solvent or kerosene and a soft rag. Do not

use lacquer thinner, paint thinner, or gasoline.

These will damage painted surfaces.

4. Coat all machined surfaces with a very light film

of oil to inhibit rust.

5. Carefully move the shear, brake, and roll to a

work bench or stand. Machine location must

allow free access on all sides.

6. Bolt the machine to a stand or a workbench. If

using a stand, the stand must be boltedto the

floor. If using a work bench, the bench must be

bolted to the floor.

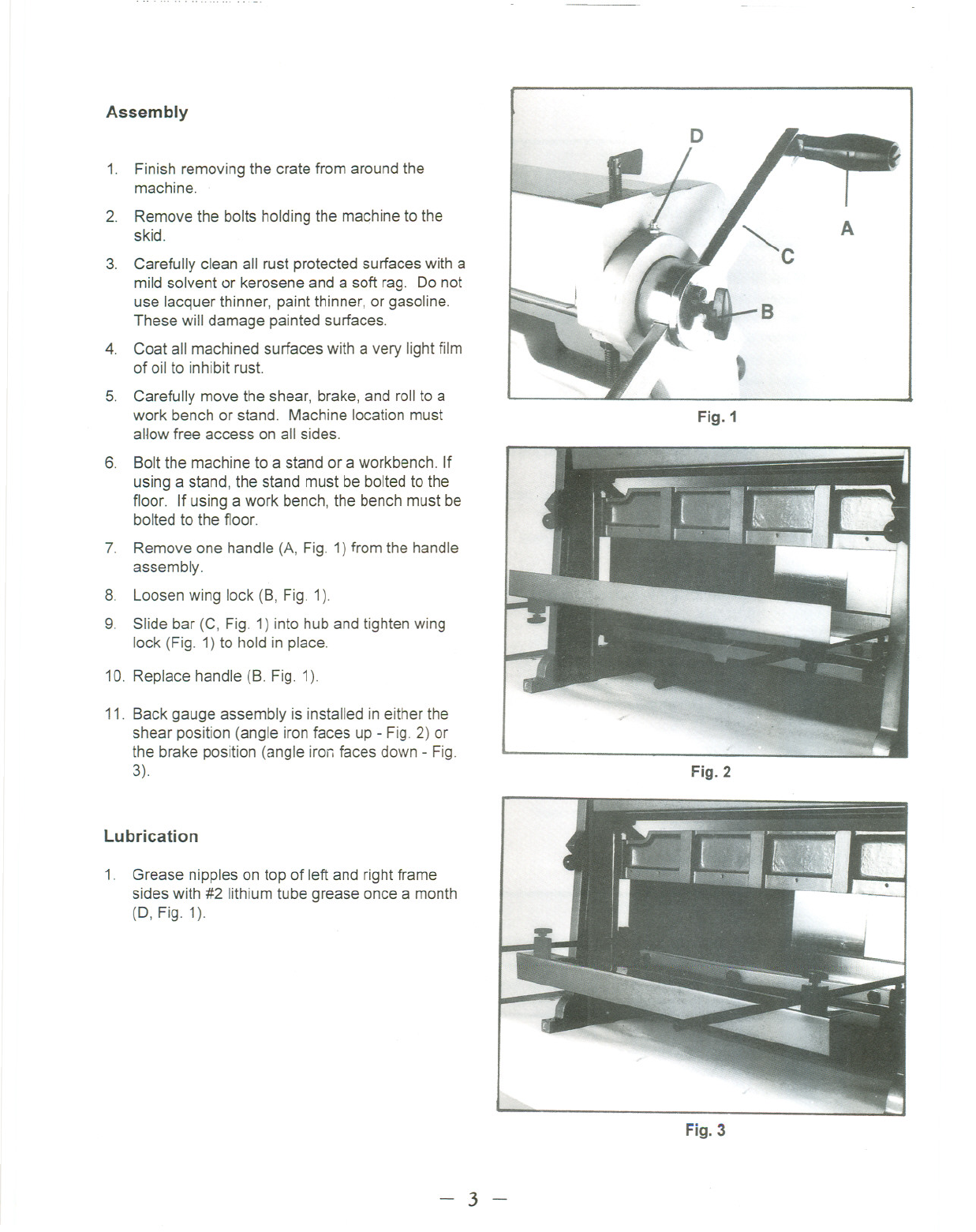

7. Remove one handle (A, Fig. 1)from the handle

assembly.

8. Loosen wing lock (B, Fig. 1).

9. Slide bar (C, Fig. 1) into hub and tighten wing

lock (Fig. 1)to hold in place.

10. Replace handle (B. Fig. 1).

11. Back gauge assembly is installed in either the

shear position (angle iron faces up - Fig. 2) or

the brake position (angle iron faces down - Fig.

3).

Lubrication

1. Grease nipples on top of left and rightframe

sides with #2 lithium tube grease once a month

(0, Fig. 1).

- 3 -

A

t

Fig. 1

Fig. 2

Fig. 3