ADJUSTMENTS

Introduction

WARNING: Unless specifically required, DO

NOT have engine running when servicing or

making adjustments to tractor. Place control

levers in the park brake position and remove

ignition switch key. Repairs or maintenance

requiring engine power should be performed by

trained personnel only. To prevent carbon

monoxide poisoning, be sure proper ventilation

is available when engine must be operated in an

enclosed area. Read and observe safety warnings

in front of manual.

Your Hustler Z or Super Z was adjusted before it left the

factory and was checked during predelivery setup.

However, after start-up and continued use, a certain amount

of break-in wear will cause some adjustments to change.

Remain alert for unusual noises, they could be signaling

a problem. Visually inspect the machine for any abnormal

wear or damage. A good time to detect potential problems

is while performing scheduled maintenance service.

Correcting the problem as quickly as possible is the best

insurance.

WARNING: Keep your machine clean and

remove heavy deposits of trash and clippings,

they can cause engine fires and hydraulic

overheating as well as excessive belt wear.

Clear away heavy build-up of grease, oil and dirt,

especially in the area of reservoir and oil and engine

combustion air; minute dust particle are abrasive to close-

tolerance engine and hydraulic assemblies.

Some repairs require the assistance of a trained service

mechanic and should not be attempted by unskilled

personnel. Consult your Hustler service center when

assistance is needed.

Torque values

WARNING: Particular attention must be given

to tightening the drive wheel lug nuts, wheel

motor nuts, and blade spindle bolts. Failure to

correctly torque these items may result in the

loss of a wheel or blade, which can cause serious

damage or personal injury.

Torque values given below:

Ft-lbs. Nm

Wheel (lug) nuts ................................65-75......88.14-101.7

Wheel motor nut (Hustler Z) .........350-375 .....474.6-508.5

Wheel motor nut (Super Z)............290-310 .....393.2-420.4

Blade spindle bolt top........................65-75......88.14-101.7

Blade spindle bolt bottom

(spindle with blade saddle)......65-75......88.14-101.7

Blade spindle bolt bottom

(spindle without blade saddle) ....118...........160.0

It is recommended that these be checked after the first 2

hours of operation, initially and every 50 hours following

removal for repair or replacement.

For engine torque values, see engine owner’s manual.

For all other torques refer to the parts manual for

standard torque chart.

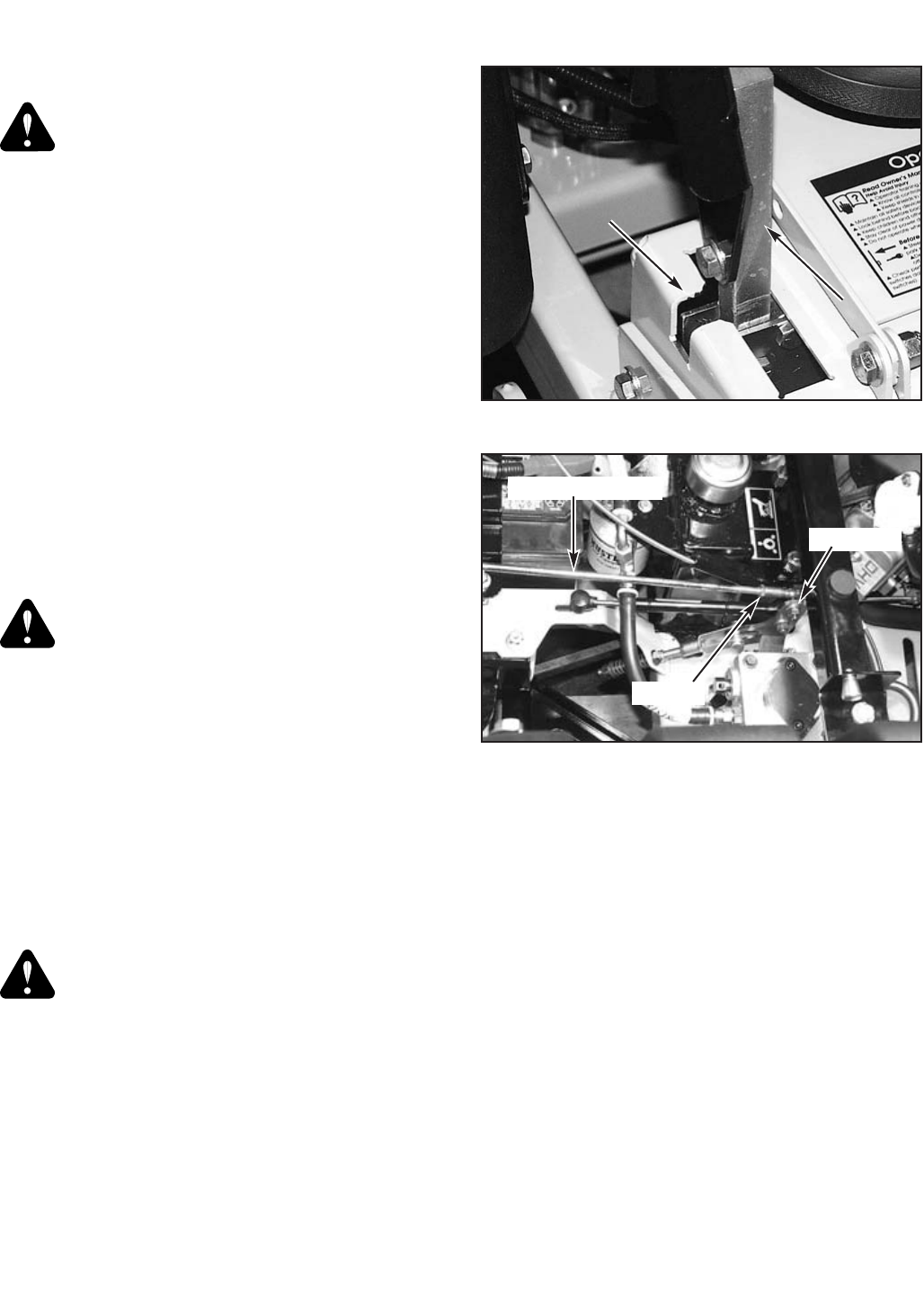

Steering linkage

The neutral adjustment for the control levers in the neutral

position is discussed in this section.

The tractor steering has been factory adjusted to eliminate

creeping when the control levers are in the neutral position

(Fig. 5-1). However, should the tractor begin to creep, the

control lever linkage can be adjusted as follows:

Control Lever Neutral Adjustment

Before considering any adjustment, check the tire air

pressure and make certain hydraulic system oil is at

operating temperature. Unequal tire pressure will cause the

tractor to drift to one side. Refer to tire pressure information

in the Maintenance section of this manual.

Fine adjustment to the unit’s steering is made with the

adjustable pump linkage rods located between the control

5-1

375527_0406

Figure 5-1

PPaarrkk bbrraakkee sslloott

CCoonnttrrooll lleevveerr iinn tthhee

nneeuuttrraall ppoossiittiioonn

Control

lever

Figure 5-2

Pump linkage rod

Pump arm

Jam nut