General engine maintenance

Detailed instructions and recommendations for break-in

and regular maintenance are specified in the Engine

Owner’s manual. Please refer to this manual for engine

servicing, lubricating oil levels with quality and viscosity

recommendations, bolt torques, etc. The engine warranty is

backed by the manufacturer. Special attention should be

paid to applicable data which will not be duplicated here.

IMPORTANT: Refer to the Kohler EFI engine owner’s

manual for specific cleaning instructions.

Belt replacement

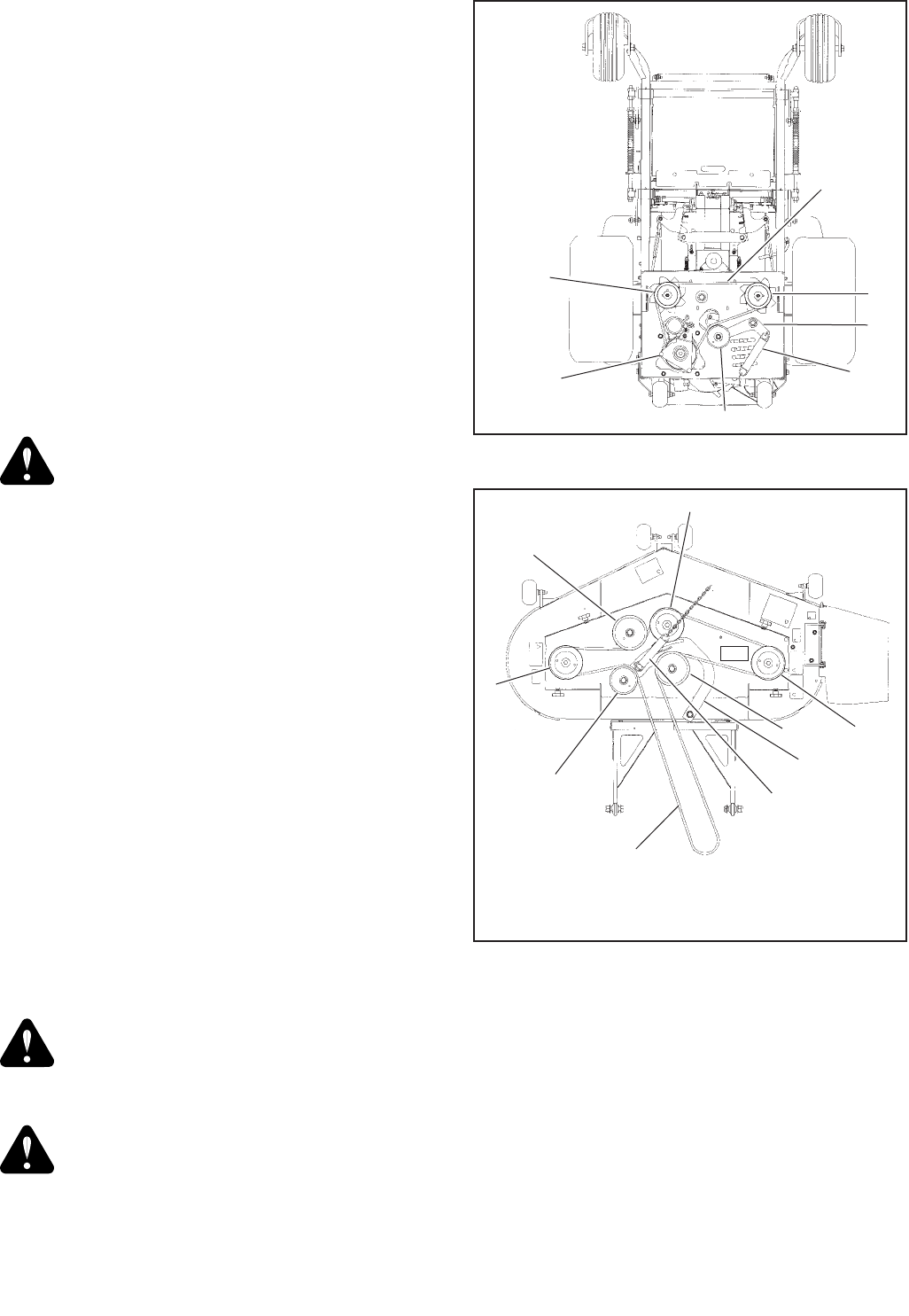

Figures 4-15, 4-16, 4-17, 4-18 and 4-19 show diagrams

and descriptions of the unit’s belt drive systems.

Inspect these belts frequently for wear and serviceability.

Replace a belt that shows signs of severe cuts, tears,

separation, weather checking and cracking, or burns caused

by slipping. Slight raveling of belt covering does not

indicate failure, trim ravelings with a sharp knife.

WARNING: If the pump belt fails, loss of

control will occur especially when operating on a

slope. If you lose steering control while

operating the machine, place the steering

control levers in the park brake position

immediately. Inspect the machine and involve

your Hustler dealer to resolve the problem

before continuing to operate.

Inspect the belt pulley grooves and flanges for wear. A

new belt, or one in good condition, should never run against

the bottom of the groove. Replace the pulley when this is

the case, otherwise belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or

damage the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt

dressings. Any of these will destroy the belt composition in

a very short time.

Mower blade maintenance

Check the mower blades daily, they are the key to power

efficiency and well groomed turf. Keep them sharp, a dull

blade will tear rather than cut the grass, leaving a brown

ragged top on the grass within a few hours. A dull blade

also requires more power from the engine.

Replace any blade which is bent, cracked or broken.

WARNING: Never attempt to straighten a bent

blade by heating, or weld a cracked or broken

blade as the blade may break and cause serious

injury.

DANGER: Never work with blades while

engine is running or deck clutch is engaged.

Always place deck clutch in the disengaged

position, place steering control levers in the park

brake position and turn engine off. Block up

mower when you must work under it. Wear

gloves when handling blades. Always check for

blade damage if mower strikes rocks, branches

or other foreign object during mowing!

Mower blade removal

On spindles with blade saddles, use a 3/4" wrench to

remove the 1/2" cap screw holding the blade to the spindle

saddle from underneath. On spindles without blade saddles,

use a 15/16" wrench to remove the 5/8" cap screw holding

the blade to the spindle shaft from underneath. NOTE: On

rear discharge decks the right blade rotates opposite of the

other two blades. Therefore, it has a left hand threaded bolt.

It will be necessary to loosen it by turning it clockwise.

Figure 4-15

1

3

2, 6

4

5

1. Pump belt

2. Engine pulley

3. Pump idler pulley

4. Pump idler arm

5. Pump pulley

6. Electric deck clutch

7. Pump idler spring

7

Viewed from

bottom for unit

5

Figure 4-16

1

Deck Belt Drive Layout

1. Spindle drive belt

2. Deck blade spindle pulley

3. Spindle belt tension idler

4. Spindle belt tension idler spring

(9.0" at operation)

5. Deck belt idler

6. Idler arm

2

2

2

6

4

5

3

5

4-11

375527_0406

Side dischage deck