111782_0910 5-1

MAINTENANCE

Blower housing and transfer tube

WARNING: Never work on the blower assembly or

mower deck when the tractor engine is running.

WARNING: Clean flammable material from machine.

Prevent fires by keeping engine compartment, top of

deck, exhaust area, battery, hydraulic lines, fuel line,

fuel tank and operator’s station clean of accumulated

trash, grass clippings, and other debris. Always clean

up spilled fuel and oil.

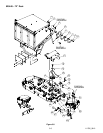

The blower and tube assembly (Figure 5-1) should be kept

clean and free of any accumulation of matted clippings or other

obstructions. Occasional clogging may also occur when

working in heavy, wet or matted grass.

WARNING: Never place hands or feet into the blower

housing spout. There is an impeller located inside the

housing that will cause severe injury. Use a probe to

clean debris from spout.

WARNING: Never engage mower deck unless the

catcher box is installed and the door is closed. Also,

the transfer tube assembly must be in place on the

blower outlet and the box assembly and the bungee

cord is connected.

To service the blower housing: remove the clevis pin and

swing the housing away from the deck.

To service the transfer tubes, remove the tube assembly from

the unit. The tube assembly can be cleaned by using soapy

water and washing the inside of the tubes with a pressure

washer. Rinse with water.

To clean the catcher box, use a power washer.

Blower drive belt

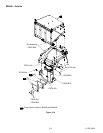

The blower drive belt (Figure 5-2) is located under the belt

shield. This belt is spring tensioned and should not need

adjustment. When replacing the belt the spring extension

should be 6” hook to hook.

To inspect or replace, remove the clevis pin and swing the

housing open. This loosens the belt and allows it to be

removed.

When belt replacement becomes necessary, check the

condition of the pulleys. Clean the grooves and check for

excessive wear. A new belt should not run against the bottom of

groove. If it does bottom out, the the pulley needs replacing.

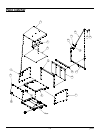

Blower spindle jack shaft

The blower spindle jack shaft assembly requires lubrication

after every 500 hours of use or annually, whichever occurs first.

The spindle is equipped with two grease zerks (Figure 5-3).

They are accessible by unlatching the blower housing from the

deck and pivoting it outward. Use SAE multi-purpose grease,

fill until grease flows from side of zerk (one or two ounces

maximum).

Figure 5-1

Figure 5-2

Blower

assembly

Tube assembly

Belt

Spring