14 - English

Operation Operator's Manual CS 2512

Operation

Sawing

When all the equipment has been assembled cutting can

start. In order for the saw to cut as efficiently as possible it

should be started as follows:

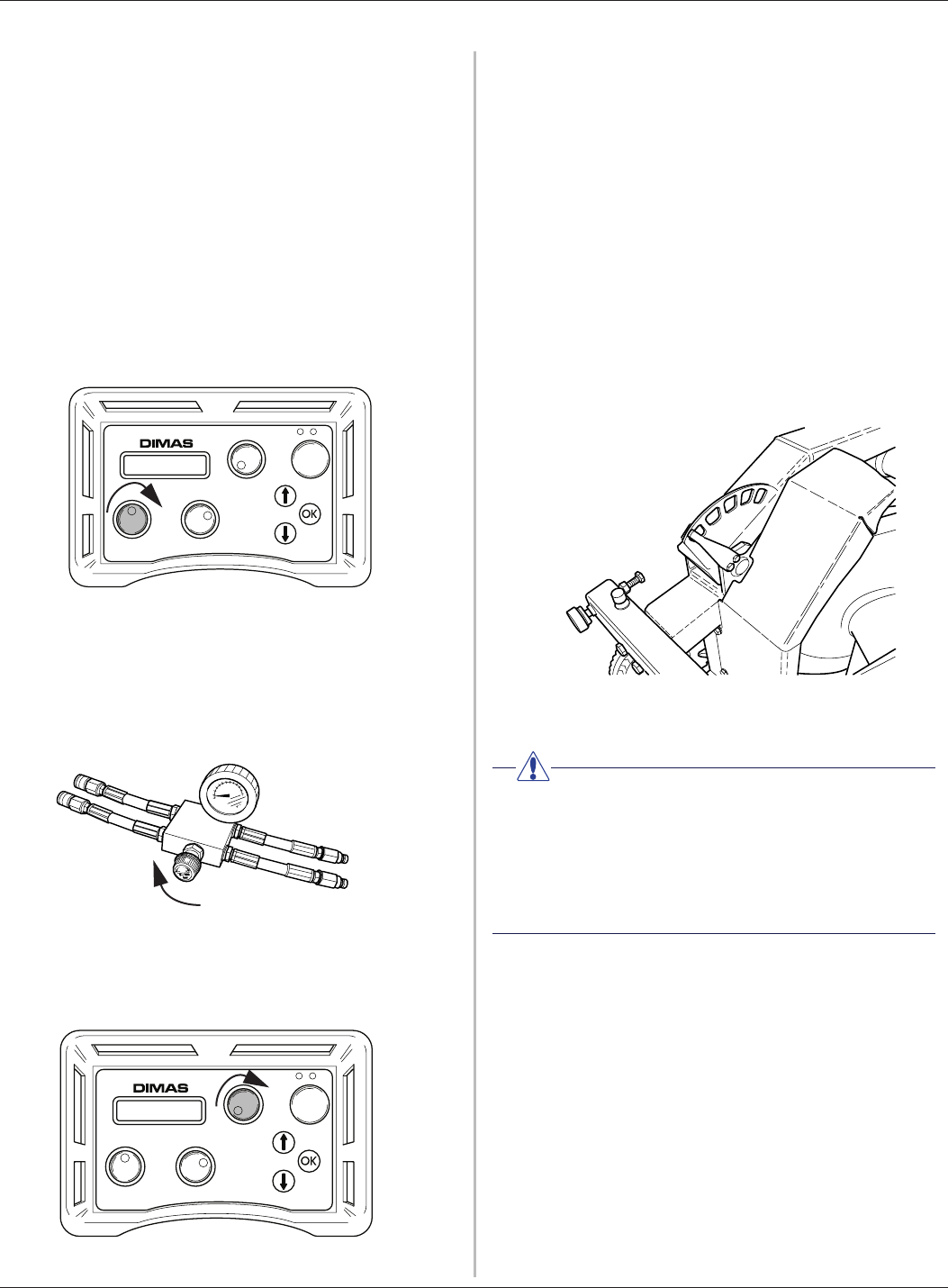

1. Close the valve on the pressure reduction block by

turning the knob anti-clockwise until it stops and then

two turns back.

2. Start the hydraulic unit.

3. Set the feeding flow on the unit to max by turning the

control on the remote control clockwise.

4. Tension the wire by carefully turning the knob on the

pressure reduction block clockwise until the wire is

tensioned sufficiently. Make sure to always check that

the wire is seated correctly in all the wheels on the

saw.

5. Start the motor's rotation by turning the control for

motor rotation on the remote control clockwise.

6. Carefully increase the motor speed by turning the

control for motor rotation. A suitable working pressure

when cutting usually lies between 100 and 130 bar, but

varies depending on how many wheel sets are used in

the magazine, how much wire is in use and the

hardness of the material to be cut.

7. As the material is cut away the working pressure

drops, which is shown on the display, and the

magazine must then be tensioned. Do this by turning

the knob on the pressure reduction block clockwise.

8. The output tension on the magazine is shown by an

indicator on the machine (shown in the min position).

When the magazine cylinder is fully tensioned, the

machine must be stopped and the wire must be wound

around a new wheel set. Then continue to cut as

above.

CAUTION

In order for the water to cool the wire as

intended during cutting, it is essential to adjust

the position of the cooling water as the

material is cut. Remember to always stop the

machine when you do this.

Finishing sawing

1. Lower the speed on the wire and allow the motor to

stop completely.

2. Fold up the magazine arm.

3. Disconnect the incoming mains cable from the

hydraulic unit.

4. Disconnect the hydraulic hoses and the water hose

from the saw unit.

5. Other steps are done in the reverse order.