14 - English

Assembling/Installing equipment Operator's Manual CS 2512

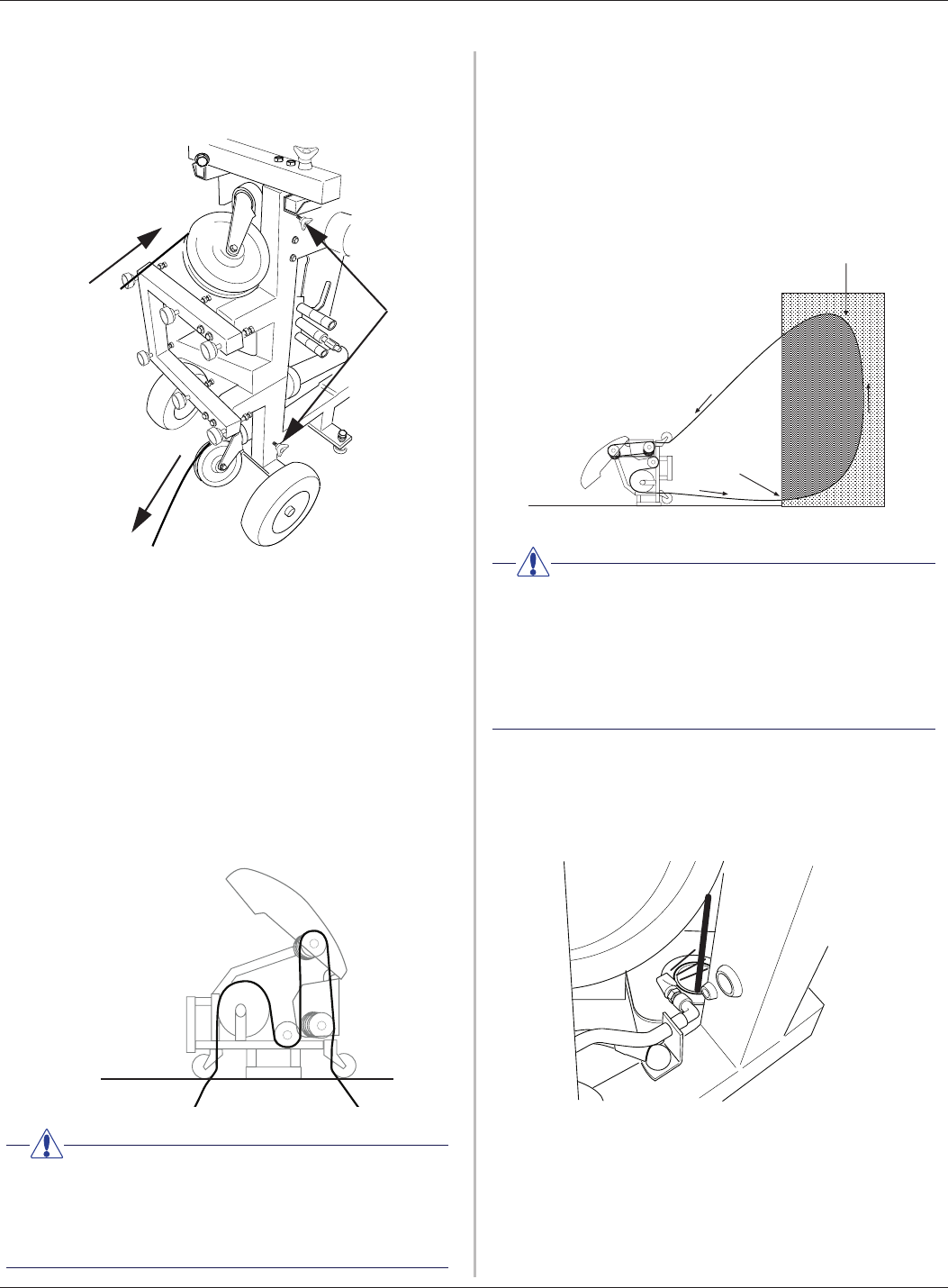

5. Thread the wire around the drive wheel and out

through the hole by the second swivel wheel. The

swivel wheel can rotate and be locked in the required

position by turning the marked (A) knobs.

6. Before the joints on the wire are connected, the wire

should be twisted 1 to 2 turns per metre wire used. It is

important to twist the wire in the same direction as it is

spun. This is to give as even wear as possible on the

wire’s diamond segments.

7. Lock the wire with a pin. If there are no end sleeves on

the wire, these must be spliced on to the wire. A

special pair of wire pliers must be used. If you are

unsure about which model you should use, contact

your DIMAS dealer.

8. When the wire is routed correctly it should run through

the machine as in the figure below:

CAUTION

A used wire must always be run in the same

direction, as it was previously run in order to

prevent unnecessary wear.

Placement of the cooling water

Husqvarna CS 2512 is equipped with two outlets for the

cooling water. Ideally, Husqvarna water spears can be

connected to these. The water spears are then placed

where the wire enters the concrete. In this way the wire

takes water with it into the cut, which results in the

concrete dust binding and that the wire is cooled

efficiently.

CAUTION

In order for the water to cool the wire as

intended during cutting, it is essential to adjust

the position of the cooling water as the

material is cut. Remember to always stop the

machine when you do this.

In addition to the cooling water from the water spear, the

wire is rinsed by the two swivel wheels on the machine.

This is to keep the wire as clean as possible, which means

that the saw can work with less friction losses and greater

efficiency as the wire becomes cleaner.

a

WATER

WATER