3

ADJUSTMENTS FORADJUSTMENTS FOR

ADJUSTMENTS FORADJUSTMENTS FOR

ADJUSTMENTS FOR

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

AXLE HEIGHT ADJUSTMENTAXLE HEIGHT ADJUSTMENT

AXLE HEIGHT ADJUSTMENTAXLE HEIGHT ADJUSTMENT

AXLE HEIGHT ADJUSTMENT

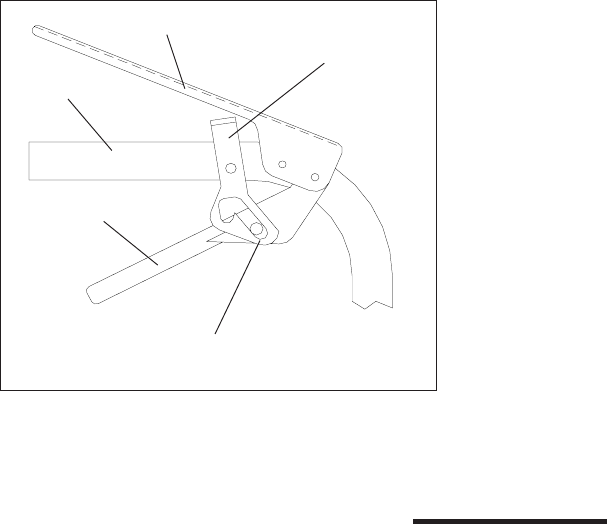

1. To adjust rear axle, stop engine and place drive levers

in the neutral lock position, remove spark plug wire.

2. Remove lower belt shield from underside of rear deck

for better access to axle adjustment bolts.

3. Loosen axle pivot bolts and axle adjustment bolts.

See figure # 1.

4. Place a jack under center of rear deck raise the jack

slightly so axle adjustment bolts may be removed.

5. With the jack raise or lower the rear deck to the desired

position using the chart to ensure proper height. Reinstall

the axle adjustment bolts and tighten.

A tapered punch may be used to help align the holes.

See figure #1.

NOTE:

It may be necessary to readjust drive and brake linkages.

NOTE:

To achieve the best quality cut, the blades should be

level with the ground or slightly tipped forward

BRAKE / TRACTION ADJUSMENTBRAKE / TRACTION ADJUSMENT

BRAKE / TRACTION ADJUSMENTBRAKE / TRACTION ADJUSMENT

BRAKE / TRACTION ADJUSMENT

1. Disconnect the brake linkage from the brake band

arm.

2. With the mower in gear, place the traction levers in the

drive position. Firmly pull back on the handles until the

tires slide to seat the wheel drive belts into the pulleys.

3. Measure the clearance between the bottom of the

traction lever rod and the bottom of the thumb latch slot.

It should be between 3/16" to 1/4", but not exceeding 1/

4". See Figure # 3

HANDLE

TRACTION LEVER

THUMB LATCH

3/16" to 1/4" CLEARANCE

O.P. LEVER

Figure 3

OPERATOR PRESENCE SWITCH ADJUSTMENTOPERATOR PRESENCE SWITCH ADJUSTMENT

OPERATOR PRESENCE SWITCH ADJUSTMENTOPERATOR PRESENCE SWITCH ADJUSTMENT

OPERATOR PRESENCE SWITCH ADJUSTMENT

The operator presence switches can be adjusted by

loosening the screws on the side of the O.P. lever

linkage and sliding the switch up or down. The O.P.

switch should have a 1/32" to 1/16" gap between the

plunger and the bottom side of the control panel when

operator presence levers are released.

BLADE SWITCH ADJUSTMENTBLADE SWITCH ADJUSTMENT

BLADE SWITCH ADJUSTMENTBLADE SWITCH ADJUSTMENT

BLADE SWITCH ADJUSTMENT

The blade engagement switch can be adjusted by

loosening the screws on the flange under the control

panel and moving the switch in or out. The blade switch

should be adjusted so the plunger is fully depressed

when the engagement lever is fully disengaged.

ADJUSTMENTS - DRIVE BELTSADJUSTMENTS - DRIVE BELTS

ADJUSTMENTS - DRIVE BELTSADJUSTMENTS - DRIVE BELTS

ADJUSTMENTS - DRIVE BELTS

For all drive belts, tension should be set so that belt

vibration is minimized or eliminated when belts are

moving during normal operation. A properly tensioned

belt should have 1/4" to 3/8" deflection at the center of

belt span between pulleys when blades are engaged.

Blade drive belt tension is preset at the factory.

NOTE:NOTE:

NOTE:NOTE:

NOTE:

DO NOT over tighten belt. Excessive tension will

decrease belt and spindle bearing life.

4. If the clearance is less than 3/16", disconnect the

traction rod from the traction lever by removing the

hairpin cotter.

5. Adjust the traction rod to the proper clearance by

screwing it out of the swivel if clearance is less than 3 /

16".

NOTE:NOTE:

NOTE:NOTE:

NOTE:

More or less brake pressure may be desired depending

on the operator or conditions of operation. To increase

pressure tighten the wing nut on the brake linkage.