MAINTENANCE

19

1741506

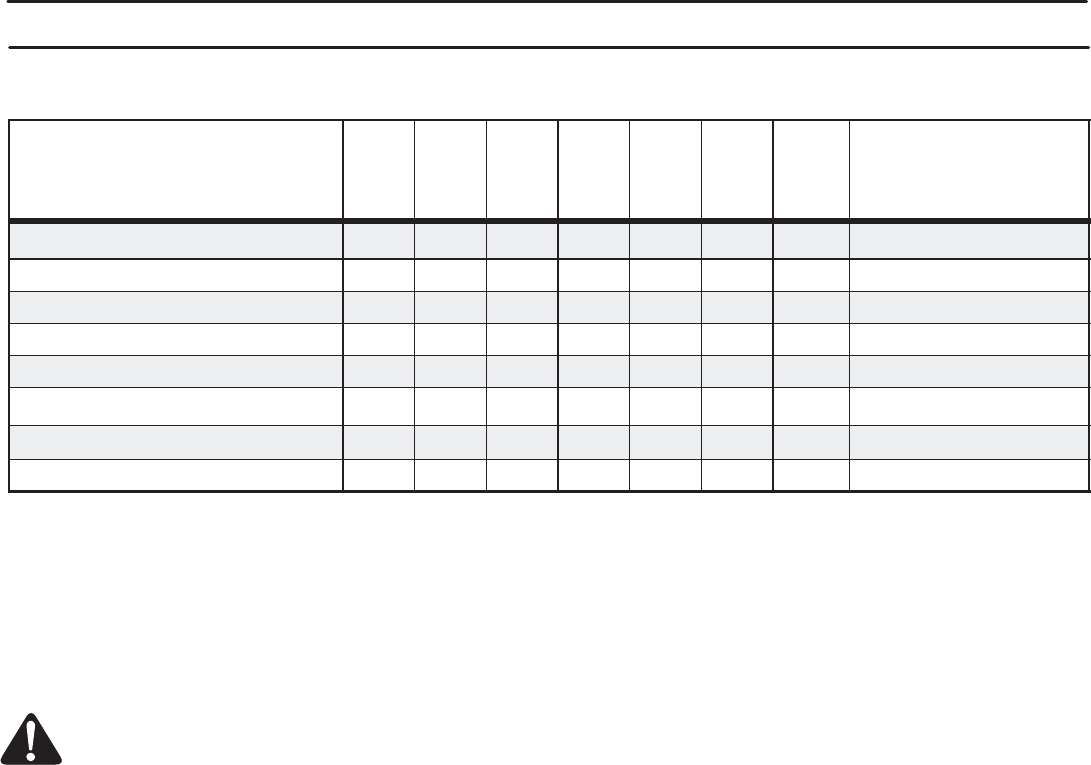

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

service.

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

Each

Season

Before

Storage

SERVICE DATES

Check And Tighten All Screws and Nuts

√ √

Check Spark Plug

√ √

Check Drive Belt

√

Check Fuel

√

Drain Fuel

√

Lubricate Chute Control Flange

√

Check Adjustment of Auger Control Cable

√

Auger Drive Belt

√

NOTE: Use the following maintenance section

to keep your unit in good operating condition.

All the maintenance for the engine is in the engine

manufacturer’s instructions. Before you start the

engine, read this book.

WARNING: Before you make an inspec-

tion, adjustment (except carburetor), or

repair, disconnect the wire from the spark plug.

EMISSIONS CONTROL

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by

any non-road engine repair establishment or indiv-

However, to obtain a “no charge” emissions control

service, the work must be performed by a factory author-

ized dealer. See the Emissions Warranty.

GENERAL RECOMMENDATIONS

The warranty on this snowthrower does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator must

maintain the snow thrower as instructed in this manual.

ENGINE POWER RATING INFORMATION

The gross power rating for individual gas engine models

is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque Rating

Procedure), and rating performance has been obtained and

corrected in accordance with SAE J1995 (Revision 2002-05).

Torque values are derived at 3060 RPM; horsepower values

are derived at 3600 RPM. Actual gross engine power will be

lower and is aected by, among other things, ambient oper-

ating conditions and engine-to-engine variability. Given

both the wide array of products on which engines are

placed and the variety of environmental issues applicable

to operating the equipment, the gas engine will not develop

the rated gross power when used in a given piece of power

equipment (actual "on-site" or net power). This dierence

to due to a variety of factors including, but not limited to,

accessories (air cleaner, exhaust, charging, cooling, carbur-

etor, fuel pump, etc.), application limitations, ambient oper-

ating conditions (temperature, humidity, altitude), and

engine-to-engine variability. Due to manufacturing and

capacity limitations, Briggs & Stratton may substitute

an engine of higher rated power for this Series engine.