38 – English

Assembly 334T, 338XPT (continued)

WARNING!

The fuel used in the chain saw has the follow-

ing hazardous properties:

• The fluid and its vapour are poisonous.

• Can cause skin irritation.

• Is highly inflammable.

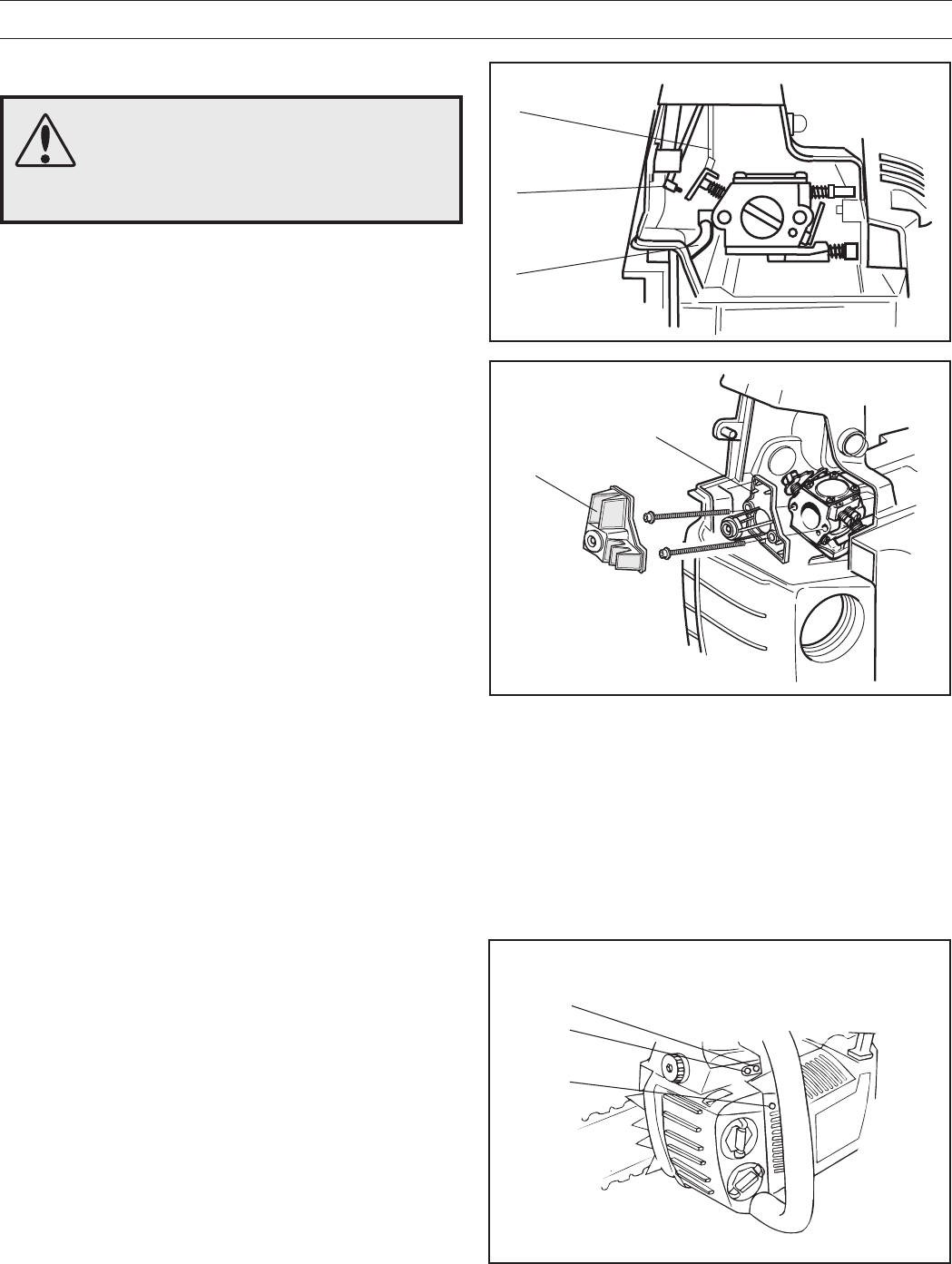

Once the carburettor has been pressure tested assembly

continues as follows:

1. Insert the carburettor a little and fit the throttle (X). Now

insert the carburettor fully.

2. Fit the fuel pipe (V) using pliers with smooth jaws. Take

care not to damage the pipe.

3. Fit the choke lever (Y) using pliers.

4. Fit the air filter holder (U), the two bolts and the air filter (S).

Tighten the bolts to1.5 Nm.

5. Fit the carburettor cover.

6. Assemble the chain and bar. See the Operator Guide.

7. The operation of the carburettor is also affected if the intake

manifold and the impulse hose are defective. These parts

should also be checked.

8. To change the manifold pipe, see the chapter “AV-system”.

9. To change the pulse tube, see the chapter “Tank unit”.

CARBURETTOR

Basic adjustment of the high and low speed

needles

Important! The following must be done before any adjust-

ments are made!

• Fit a bar and chain combination approved for this model. "See

the technical data in the Operator’s Guide".

• Tension the chain so that there is still around 0.2 tum/5 mm to

the underside of the bar.

• Fit a new air filter.

Done when the chain saw is assembled.

1. Start the engine and adjust the idling speed using the T-

screw until the chain stops.

2. Adjust the H-needle until the engine’s max. speed is 13,000

± 200 rpm. Use a screwdriver with a small blade.

3. Let the engine run at 13,000 rpm until it is warm, about 1

minute.

4. Adjust the H-needle until the engine’s speed is 13,400 rpm.

Turn the locking cap to its richest position. (Screw anti-

clockwise until it stops.)

5. Carefully knock the locking cap in position using a suitable

punch (5 mm).

6. Adjust the idling speed to 2,800 rpm.

7. Adjust the L-needle until the highest idling speed has been

reached, now screw the L-needle anticlockwise a 1/2 turn.

Use a screwdriver with a small blade.

8. Adjust the locking cap to its richest position. (Screw

anticlockwise until it stops.) Carefully knock the locking cap

in position using a suitable punch (5 mm).

L

H

T

U

S

X

Y

V