This section explains how correct maintenance and use of the right cutting equipment:

• Reduces kickback tendencies.

•Reduces the frequency of chain derailing and breakage.

•Achieves maximum cutting effect.

• Increases the service life of the chain.

The five basic rules

• Use only the recommended cutting equipment!

See «Technical Specifications» on page 3.

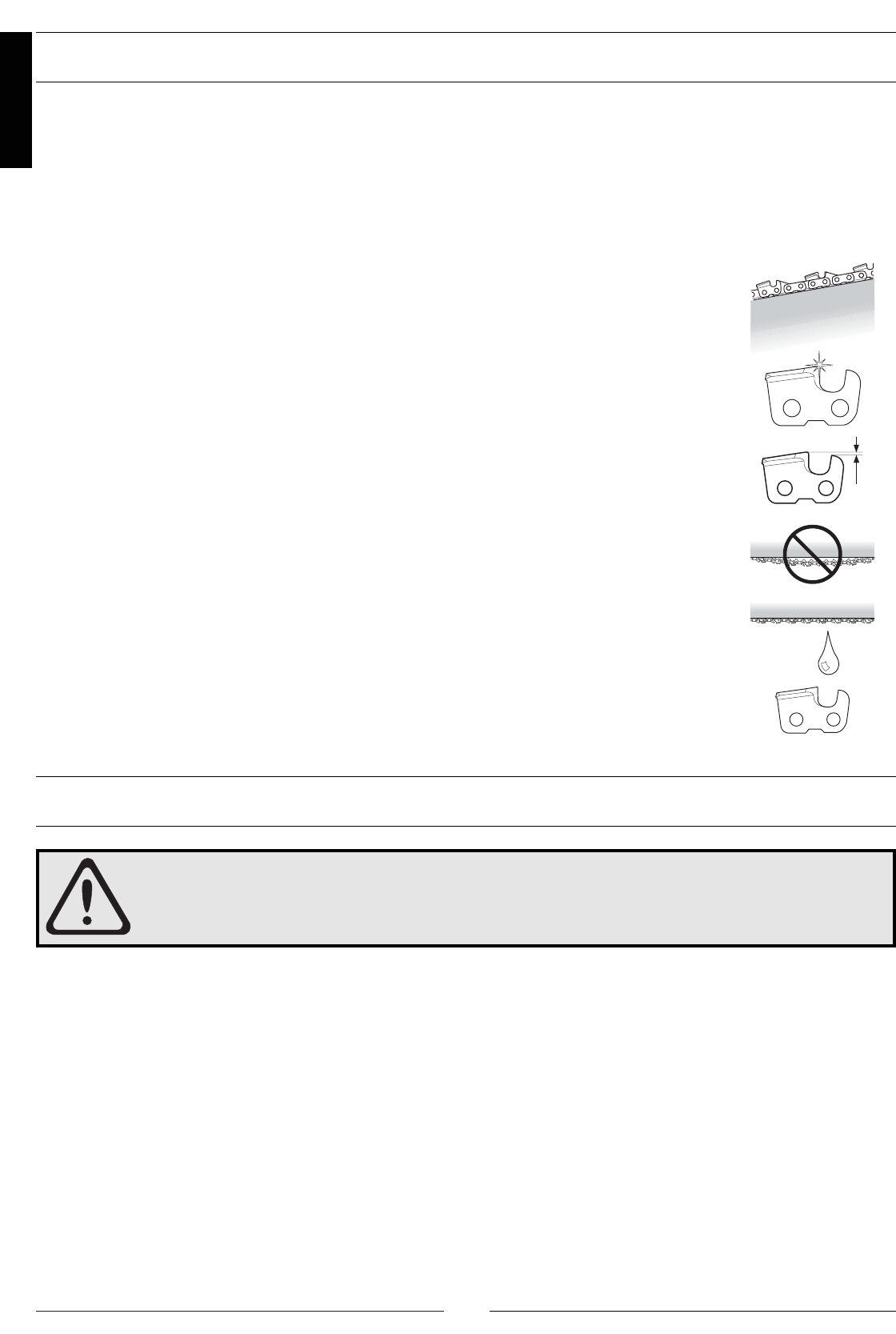

• Ensure that the cutter teeth are always correctly sharpened! Follow our

instructions and use the recommended filing guide. A chain which is

damaged or improperly maintained increases the risk of accident.

• Maintain the correct depth-gauge height.

Worn depth gauges increase the risk of kickback.

• Keep chain properly tensioned!

A loose chain derails more easily and accelerates wear on guide bar,

chain and drive socket.

• Ensure that the automatic oiling system works and that the cutting

equipment is properly maintained.

14

ENGLISH

CUTTING EQUIPMENT

CHAIN AND GUIDE BAR LUBRICATION

CAUTION!

Inadequate lubrication can lead to cutting equipment failure and serious or fatal

personal injury.

Chain oil

• The chain and bar are lubricated by an automatic oiling system. We recommend using only chain saw oil,

which is formulated for good adhesion and flow characteristics in hot or cold weather. Nonetheless, it is

important to use the viscosity appropriate to the season. Oil thickens in subfreezing temperatures and can

overload the oil pump and cause parts to fail.

• As a manufacturer of chain saws, we have developed an ideal chain oil which, being based on vegetable

oils, is completely biodegradable. We recommend our oil for the sake of your chain and guidebar and for

the sake of the environment.

•Where chain oil is not available, EP 90 gear oil may be used.

• If you need help choosing chain oil, contact your service dealer.

• Never use old motor oil!

Used motor oil contains impurities which may be harmful to oil pump, guide bar and chain.