English – 17

!

MAINTENANCE

Carburettor

Operation, Basic settings, Fine tuning

Operation

• The carburettor governs the engine‘s speed via the throttle.

Air/fuel is mixed in the carburettor. The air/fuel mixture is

adjustable. To take advantage of the engine‘s optimal output

the adjustment must be correct.

• The setting of the carburettor means that the engine is

adapted to local conditions, for example, the climate, altitude,

petrol and the type of 2-stroke oil.

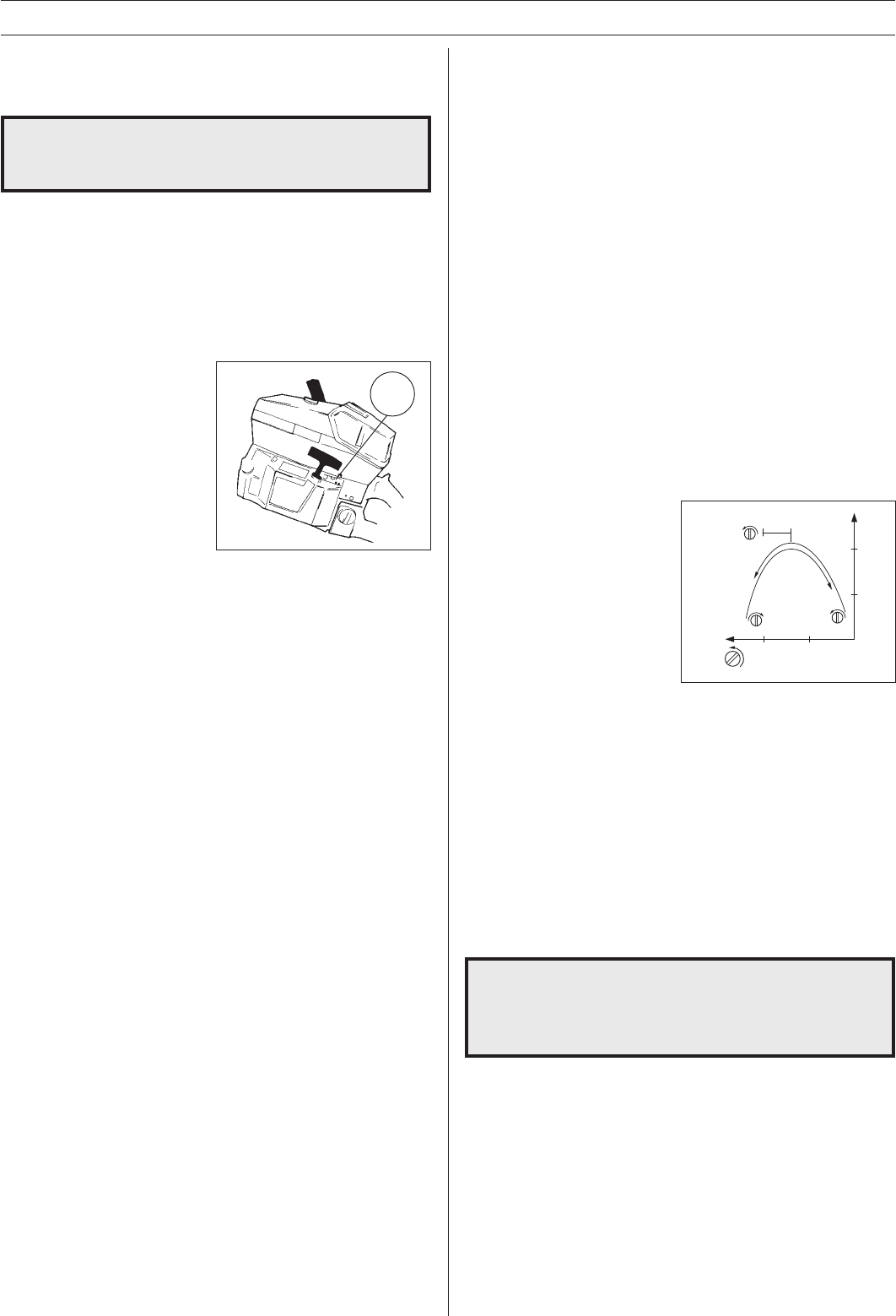

• The carburettor is equipped

with three adjustment

possibilities:

L = Low speed needle

H = High speed needle

T = Idle speed adjuster

screw

• The fuel quantity in relation to the air flow permitted by the

throttle opening is adjusted using the L and H-needles.

Turning the needles clockwise gives a leaner fuel mixture

(less fuel) and turning them anti-clockwise gives a richer fuel

mixture (more fuel). A leaner mixture gives high revs while a

richer mixture give less revs.

• The T-screw regulates the position of the throttle while the

engine is idling. Turning the screw clockwise gives a higher

idling speed while turning it anti-clockwise gives a lower idling

speed.

Basic setting

The carburettor is set to its basic setting when test run at the

factory.

The basic setting is H = 3/4 turn respective L = 1 turn.

The carburettor should be set for a richer fuel mixture

during the first 3–4 hours of use so that the engine parts

are given good initial lubrication (running-in). To set this,

adjust the maximum speed to 6-700 rpm under the

recommended maximum speed.

If you do not have the possibility of checking the maximum

speed with a tachometer, the H-needle must not be set for a

leaner mixture than stated for the basic settings.

The recommended maximum speed must not be exceeded.

NOTE! If the cutting disc rotates while the engine is idling the T-

screw should be turned anti-clockwise until the cutting disc

stops.

Fine tuning

• When the machine has been run-in the carburettor is finely

tuned. Fine tuning should be carried out by trained

personnel. The L-needle is adjusted first, then the idling

screw T and finally the H-needle. The following speed

recommendations apply:

Max. speed Idling speed

10,000 rpm 2,500 rpm

Conditions

• The air filter should be clean and the cylinder cover fitted

when all adjustments are made. If the carburettor is adjusted

with a dirty air filter a too lean fuel mixture is obtained the

next time the air filter is cleaned. This can result in serious

damage to the engine.

• Carefully screw (clockwise) the L and H needles until they

bottom. Then screw out (anti-clockwise) the needles one turn.

The carburettor now has the setting H = 1 and L = 1.

• Start the power cutter as set out in the start instructions (see

section

”Start and stop”

) and run the cutter warm for 10

minutes. NOTE! If the cutting disc rotates while the engine

is idling the T-screw should be turned anti-clockwise

until the cutting disc stops.

Low speed needle L

• Find the highest idling

speed by slowly screwing

the low speed needle

clockwise respective anti-

clockwise. When the

highest speed is found,

screw the L-needle 1/4 turn

anti-clockwise. NOTE! If the

cutting disc rotates while the

engine is idling the T-screw

should be turned anti-

clockwise until the cutting

disc stops.

Fine tuning idling T

Idling is set using the screw marked T. If adjustment is

necessary screw in (clockwise) the idling screw T with the

engine running until the cutting disc starts to rotate. Thereafter

open (anti-clockwise) until the disc stops rotating. The correct

idling speed is set when the engine runs smoothly in all

positions with a good margin to the speed when the disc starts

to rotate.

WARNING! If the idling speed cannot be

adjusted so that the disc stops, contact your

service workshop. Do not use the machine

until it has been correctly adjusted or repai-

red.

!

WARNING! The power cutter must be correctly

assembled with cutting arm and cutting head

before you start (See chapter ”

Assembly

”.)

T

L

H

L

+ 1/4