English – 21

MAINTENANCE

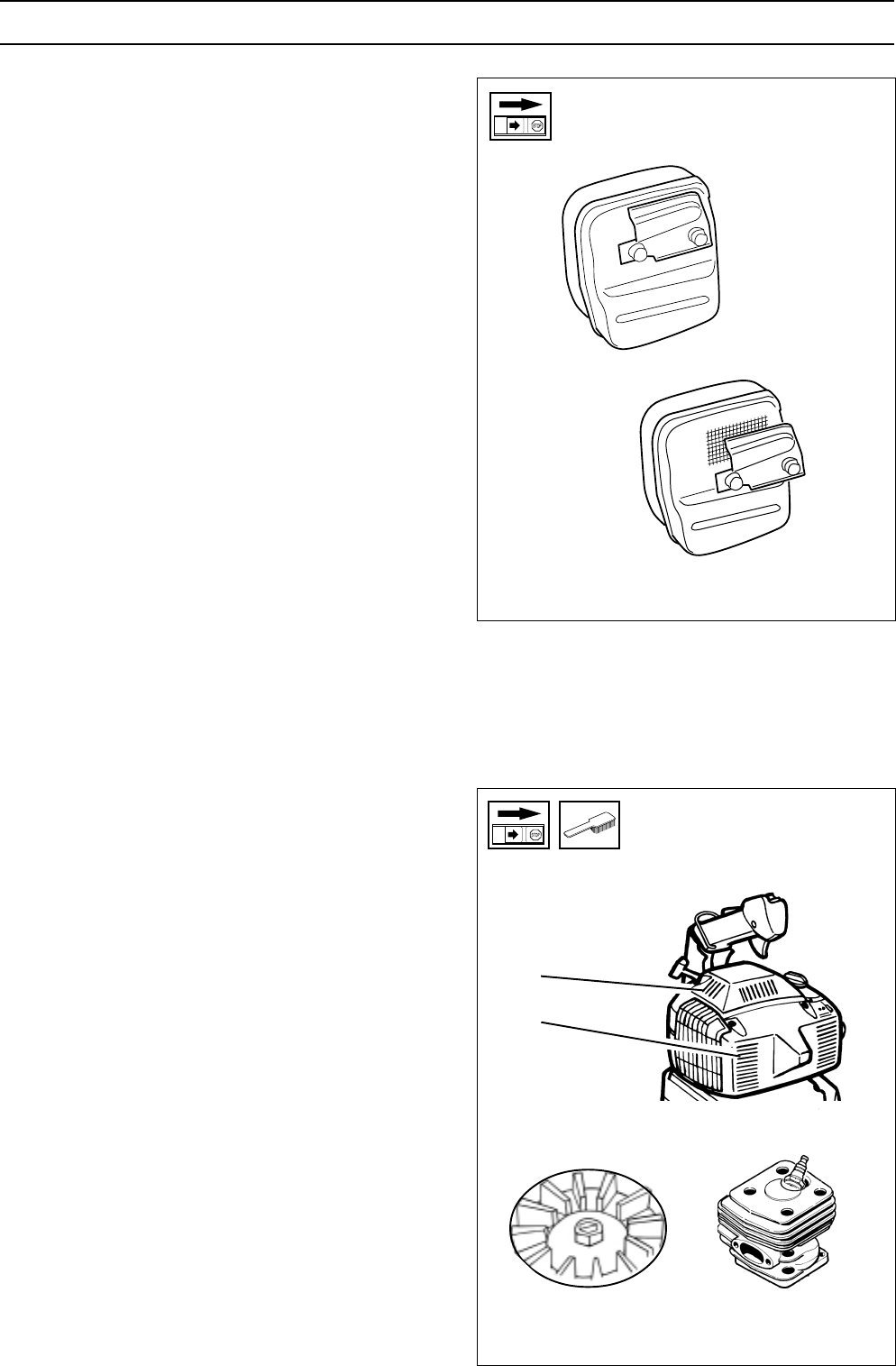

Muffler

NOTE!

Some mufflers are fitted with a catalytic converter.

See

“Technical data”

to see whether you clearing

saw is fitted with a catalytic converter.

The muffler is designed to dampen the noise level

and to direct the exhaust fumes away from the user.

The exhaust fumes are hot and can contain sparks,

which can result in fire if the exhaust fumes are

directed towards a dry and inflammable material.

Some mufflers are equipped with a special spark

arrest screen. If your machine is fitted with this type

of screen it should be cleaned regularly. This is done

using a wire brush. On mufflers without a catalytic

converter the screen should be cleaned weekly, or

replaced if necessary. On mufflers fitted with a

catalytic converter the screen should be checked

and cleaned monthly. If the screen is damaged it

should be replaced. If the screen is frequently

blocked, this can be a sign that the function of the

catalytic converter is impaired. Contact your dealer

to inspect the muffler. A blocked screen will cause

the engine to overheat resulting in damage to the

cylinder and piston. Also see under

“Maintenance”

.

NOTE!

Never use a machine with a defective muffler.

1

4

23

Cooling system

The engine is equipped with a cooling system for

maintaining the right operating temperature.

The cooling system consists of the following

components:

1. Air intake on the starter device.

2. Fan blades on the flywheel.

3. Cooling fins on the cylinder.

4. Cylinder cowling (guides cooling air flow against

cylinder surfaces).

Clean the cooling system by brushing once a week,

or more often, if necessary.

A dirty or blocked cooling system will cause the

blower to overheat and this will damage the cylinder

and piston.