GENERAL SAFETY PRECAUTIONS

16 – English

115 13 82-49 Rev.1 2009-08-21

If the chain lubrication is not working:

• Check that the oil channel in the bar is not obstructed.

Clean if necessar

y.

• Check that the groove in the edge of the bar is clean.

Clean if necessar

y.

• Check that the bar tip sprocket turns freely and that

the lubr

icating hole in the tip sprocket is not blocked.

Clean and lubricate if necessary.

If the chain lubrication system is still not working after

carr

ying out the above checks and associated measures

you should contact your servicing dealer.

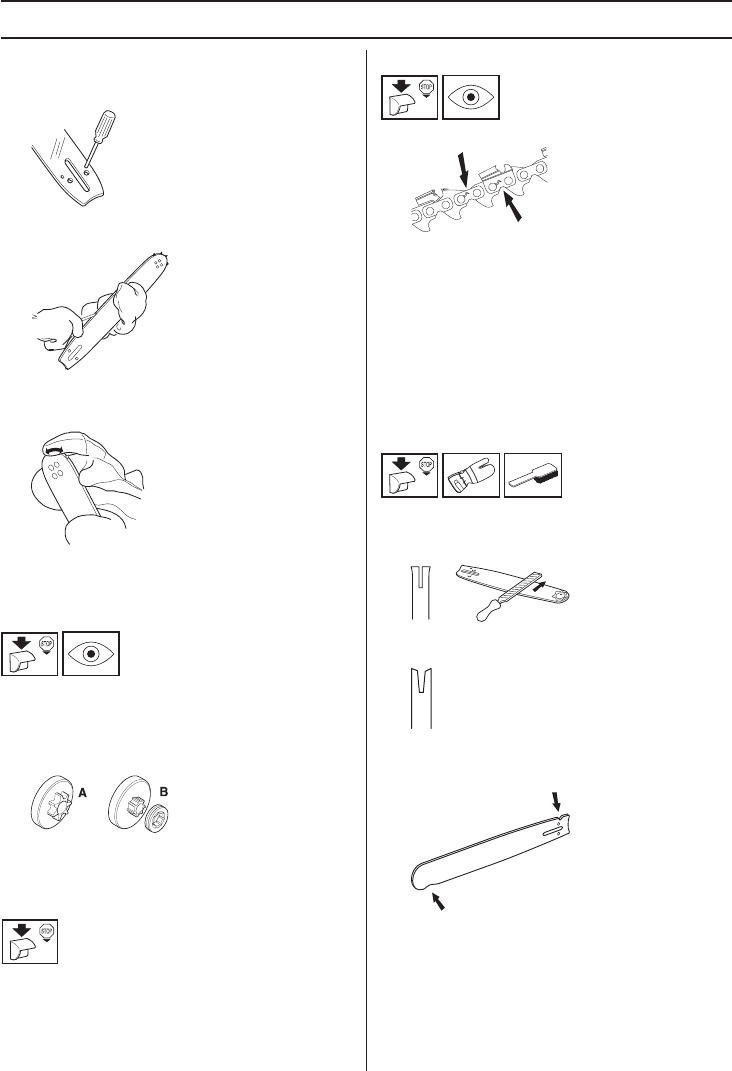

Chain drive sprocket

The clutch drum is fitted with one of the following drive

sprockets:

A Spur sprocket (the chain sprocket is welded on the

dr

um)

B Rim sprocket (replaceable)

Regularly check the degree of wear on the drive sprocket.

Replace if w

ear is excessive. Replace the drive sprocket

whenever you replace the chain.

Needle bearing lubrication

Both versions of sprockets have a needle bearing on the

drive shaft, which has to be greased regularly (once a

week). CAUTION! Use only high quality bearing grease or

engine oil.

See instructions under the heading Maintenance, Needle

bear

ing lubrication.

Checking wear on cutting equipment

Check the chain daily for:

• Visible cracks in rivets and links.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points

abo

ve.

We recommend you compare the existing chain with a

new chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to

only 0.16 inch (4 mm) the chain must be replaced.

Bar

Check regularly:

• Whether there are burrs on the edges of the bar.

Remo

ve these with a file if necessary.

• Whether the groove in the bar has become badly

w

orn. Replace the bar if necessary.

• Whether the tip of the bar is uneven or badly worn. If

a hollo

w forms on the underside of the bar tip this is

due to running with a slack chain.