953910KG141004

MAINTENANCE

1.59

1.59

90

0

CUTTERHEAD CYLINDER TO BOTTOM BLADE ADJUSTMENT

IMPORTANT : PREVENT DAMAGE - It is essential that the

relationship between the bottom blades and the cutting cylinders is

kept in good adjustment in order to ensure good cutting performance,

minimum power consumption and prolonged life for the cutting

edges.

Carry out the following procedure before commencing work and re-check

the settings every few hours.

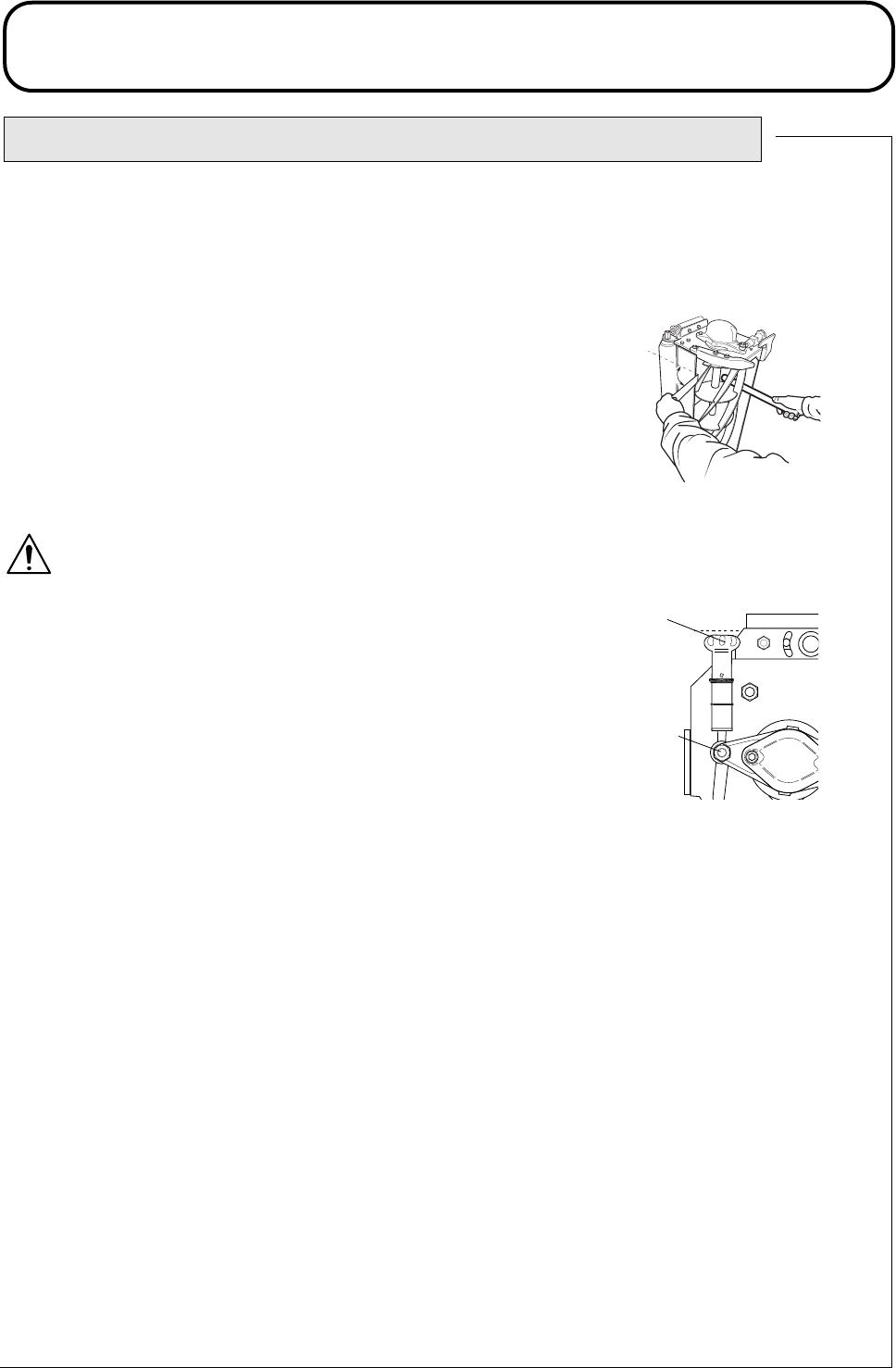

Check that the cutting cylinder is correctly set to the bottom blade by

holding a thin piece of paper between the cutting cylinder and the bottom

blade as shown. Carefully rotate the cylinder as shown and check that the

paper is cut cleanly at all points along the length of the blade. Hold the

paper at 90 degrees (right angles) to the bottom blade to obtain the correct

cutting action.

WARNING: PREVENT ACCIDENTS - Ensure that people are clear

of the cutting cylinders as rotation of one may cause others to rotate.

If adjustment is necessary proceed as follows;

Release nut 'A' 1/4 turn both ends.

Turn handwheel 'B' each end alternately whilst rotating the cutting

cylinder backwards until the bottom blade is in 'fleeting' contact with the

cylinder along its entire length. Re-check the cutting action along the

length of the bottom blade using a thin piece of paper making marginal

adjustments as necessary.

Tighten nut 'A' both ends.

If it is impossible to obtain a good clean paper cut across the entire length of the bottom blade it will

be necessary to carry out the backlapping procedure to reprocess the cutting edges. In severe cases it

will be necessary to regrind the cutting cylinder and the bottom blade, refer - BACKLAPPING /

GRINDING.

Do not be tempted to over-adjust causing heavy contact between the cylinder and bottom blade as this

will cause very rapid uneven wear to take place, leading to tramlining and waviness of the cutting

edges. The frictional losses will be high and a significant amount of power will be absorbed thus reduc-

ing the power available for cutting. The heating effect due to friction will cause excessive expansion

to take place which will further aggravate the situation by increasing the contact pressure.

If the cutterheads are allowed to operate for more than a few hours without adjustment the running

wear will eventually cause the cylinder to run out of contact with the bottom blade. At this stage very

rapid rounding of the cutting edges will occur as grass and abrasive particles pass through the

clearance between the blades.

Lack of attention to adjustment can therefore be foolhardy as maintenance costs will escalate. Quality

of cut will also be seriously affected as will the health and growth of the grass.

An experienced operator will notice when a cutterhead starts to go out of adjustment, when the grass

ceases to be cut cleanly and the cut ends become ragged.

B

A