953910KG141004

MAINTENANCE

1.55

1.55

EVERY 250 HOURS

Perform routine checks : Refer - DAILY BEFORE USE.

- EVERY 50 HOURS.

Check battery condition :

WARNING : PREVENT ACCIDENTS - Explosive gases are produced by the battery. Work in a well

ventilated area, away from all sources of ignition.

Battery fluids are corrosive. Take care to avoid contact with the skin or eyes. In the event of a spillage,

drench the affected area with water. If the eyes are affected, seek medical attention. Remove any cont-

aminated clothing and clean thoroughly before use.

When removing the battery, always disconnect the negative (-) cable first.

When replacing the battery, always connect the negative (-) cable last.

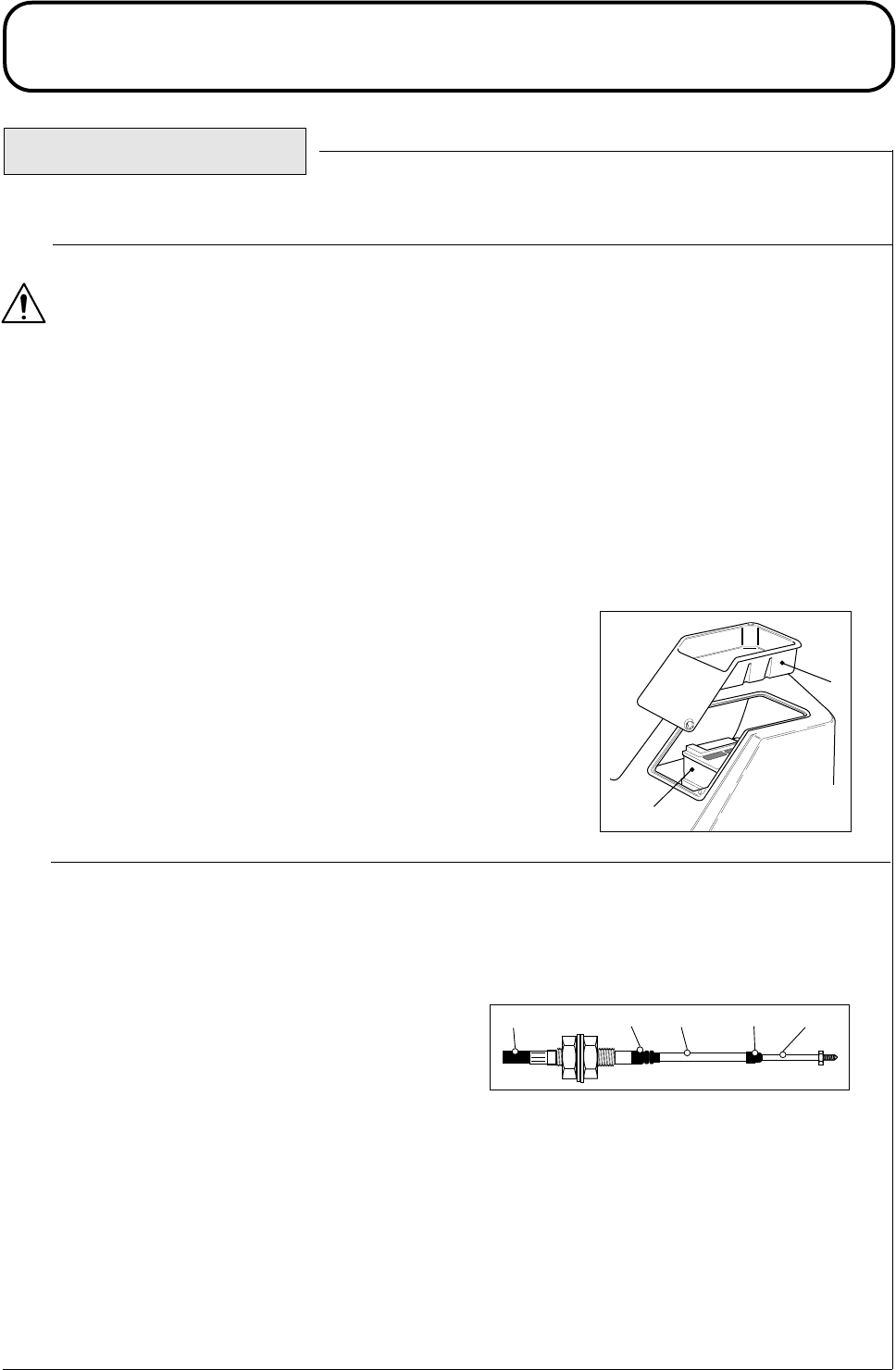

Remove the tool tray to gain access to the battery. Remove any corrosion from the battery terminals using a wire

brush and apply petroleum jelly to the terminals to prevent further corrosion. Clean the battery compartment.

Under normal operating conditions the battery will not require any further

attention. If the machine has been subject to continuous use under high

ambient temperature conditions, the battery electrolyte may require topping

up. Remove the cell covers and top up with distilled water to a height 15mm

below the top of the battery. Replace the cell covers.

IMPORTANT : PREVENT DAMAGE - Check the condition of the

battery cables. Replace cables showing signs of wear or damage and

tighten any loose connections as necessary.

Visually inspect transmission control cable and operating mechanism:

Check the condition and security of the cable and operating mechanism at the travel control pedals and trans-

mission pump ends.

- Remove build up of dirt, grit and other deposits.

- Ensure that the ball joints are securely anchored and

check that mounting brackets and cable anchors are

tight and free from cracks.

- Inspect end fittings for wear, corrosion, broken springs

and replace if necessary.

- Ensure that the rubber seals are correctly located and in good condition.

- Ensure that the articulating sleeves supporting the inner cable are in good condition and firmly attached to

the outer cable assembly at the crimped connections. If there are any signs of cracking or detachment fit

new cable immediately.

- Check that sleeves, rods and inner cable are free from bends, kinks and other damage. If there are any signs

of such failure, fit a new cable immediately.

- Check the condition of the neutralising device and replace if worn.

- With the engine switched ‘Off’, operate the pedal controls through the entire range and ensure that the

mechanism moves smoothly and freely to the neutral position without ‘Sticking’ or ‘Hanging up’.

1

2

1D924P14A

1. Battery

2. Tool Tray

Outer Cover Sleeve Rod EndRubber Seal Rubber Seal