28

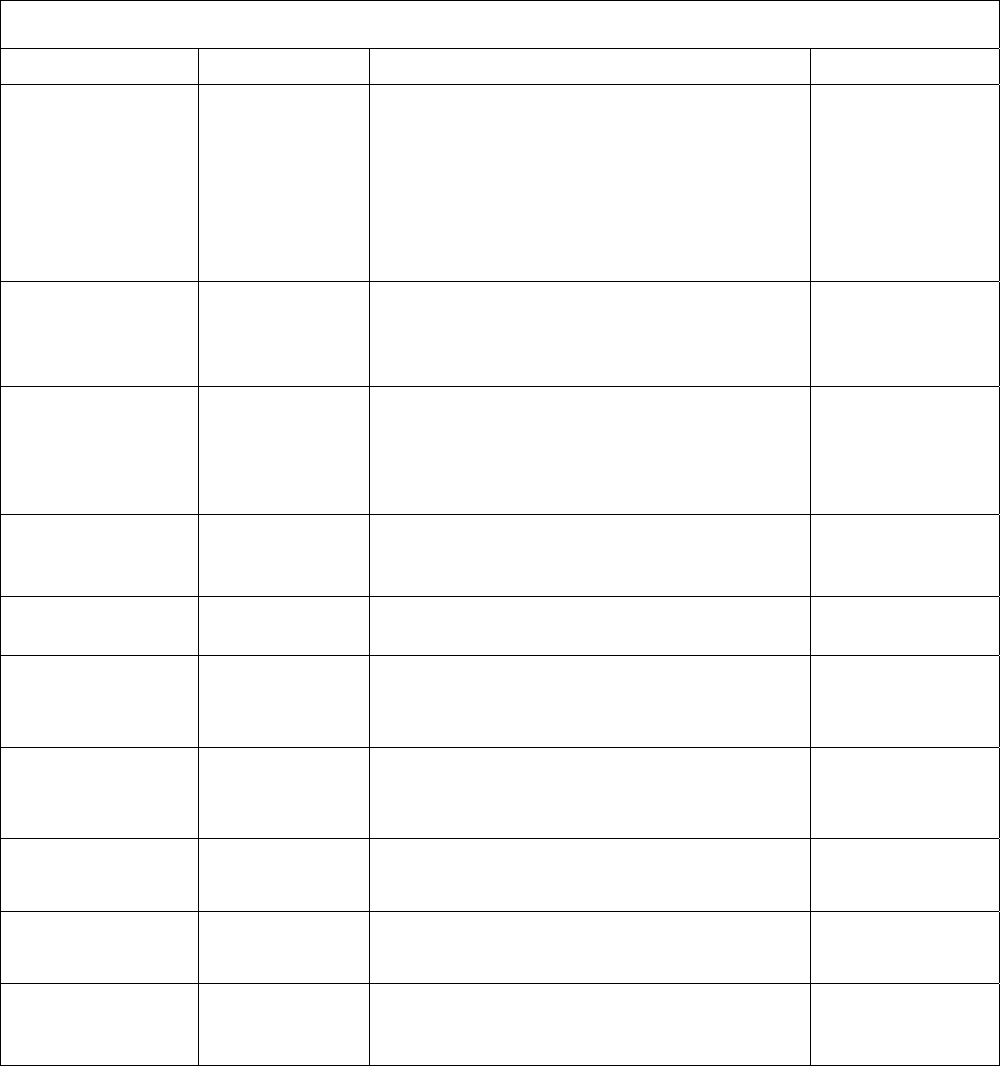

Table 5-3 Hoist Inspection Methods and Criteria (continued)

Item Method Criteria Action

Housing and

Mechanical

Components

Visual, Auditory,

Vibration,

Function

Hoist components including load blocks,

suspension housing, chain attachments, clevises,

yokes, suspension bolts, shafts, gears, bearings,

pins and rollers should be free of cracks,

distortion, significant wear and corrosion.

Evidence of same can be detected visually or via

detection of unusual sounds or vibration during

operation.

Replace

Chain Separator Visual, Measure The Chain Guide/Side Plate should be free of

cracks, distortion, significant wear and corrosion.

The “L” and "W" dimension should not be greater

than maximum value listed in Table 5-5.

Replace

Motor Brake Measure, Visual Motor brake dimension should be within the

allowable limits of Table 5-4. See Section 7.2 for

gaining access to motor brake. Braking surfaces

should be clean, free of grease/oil and should not

be glazed.

Replace

Load Sheave Visual Pockets of Load Sheave should be free of

significant wear. See Section 7.5 to gain visual

access to the load sheave.

Replace.

Pendant Control

Levers

Visual,

Function

Depressing and releasing pendant control levers

should cause hoist to operate.

Repair or replace

as necessary.

Pendant - Housing Visual Pendant housing should be free of cracks and

mating surfaces of parts should seal without gaps.

Replace.

Pendant - Tubing Visual, auditory Tubing to pendant control switches should not be

loose or be leaking air.

Repair or replace

as necessary.

Pendant - Labels Visual Labels denoting functions should be legible. Replace.

Warning Labels Visual Warning Labels should be affixed to the hoist (see

Section 1.2) and they should be legible.

Replace

Hoist Capacity Label Visual The label that indicates the capacity of the hoist

should be legible and securely attached to the

hoist.

Replace.