Page 6For replacement parts, please call 1-800-444-3353.

SKUs

91839, 91840

& 92199

Operation

Warning!! Always block the wheels before changing the

position (vertical/horizontal) of the unit.

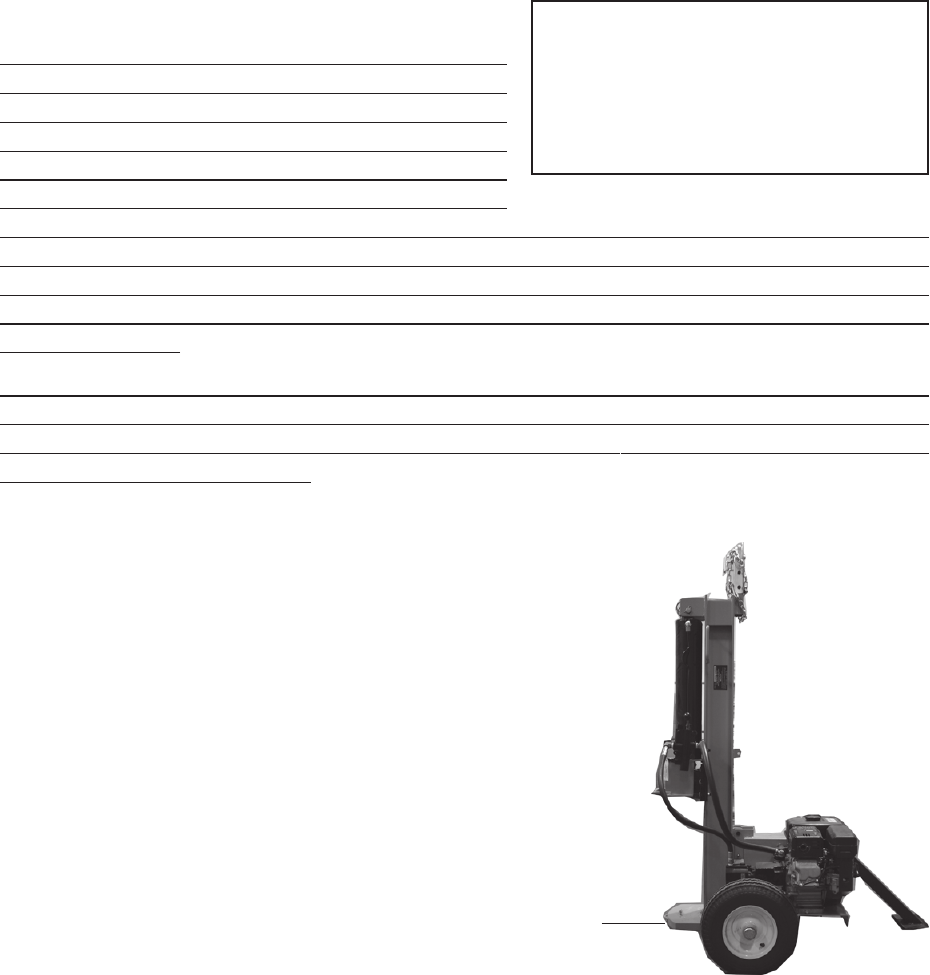

In FIGURE 1, the Rail Assembly (2) is shown in Horizon-

tal mode for operation and travel. In FIGURE 4 the unit is

shown in the vertical position. To change positions, re-

move the Hair Pin Clip (29) and the Push Pin (26). A

close-up of this Push Pin (26) is shown in FIGURE 3 on

page 5. Tilt the unit to the vertical position as shown in

FIGURE 4, and replace both the Push Pin (26)

and the Hair Pin Clip (29) into the vertical posi-

tion hole (See FIGURE 1). Reverse the process

to return to the horizontal position.

1. Remove the Oil Plug (37) and fill the tank with Hydraulic oil (not included). To check the

oil level remove the Dipstick (62), check the level then replace it. The oill should be at

the upper notch of the Dipstick. Be sure that a constant oil level of 2.5 gallons is main-

tained. See FIGURE 3 on page 5, Parts List page9, and Assembly Diagram page 10.

2. The hydraulic system must be vented during operation or it may become vacuum locked

and stop working properly. To vent the system, open the air inlet hole (See FIGURE 3)

by loosening the Oil Plug. You may have to move the o-ring to expose the air inlet vent.

When the Log Splitter is not in operation or being transported, close the air inlet hole by

tightening the Oil Plug (37).

3. Make certain that the maximum length of each log does not exceed 25 inches with a

diameter of 8 inches.

Transportation

When transporting the Log Splitter, make sure

your hitch (not included) is compatible with the

Hitch Coupler (9). Follow all of the safety warn-

ings for towing in your vehicle’s manual. Always

use the Safety Chain with Hook (4) when towing

a vehicle. Do not tow the Log Splitter at speeds

above 45 MPH. As mentioned in number 2 on page 5, always travel with the Front Leg

Assembly (11) in the horizontal position. The Rail Assembly (2) must always be secured

in the horizontal position for travelling. Note: Make sure the air inlet hole on the Oil Plug

(37) is covered when transporting. See FIGURE 3 on page 5, and refer to number 2 in

Operation below.

Pull up and down on the Hitch Coupler to make sure the hitch ball is fitting snugly in the

Hitch Coupler. There should be no play between the hitch ball and Hitch Coupler. If there

is play, tighten the Adjustment Nut until no play is present. If the Adjustment Nut is too

tight, the Handle will not lock.

Note: The hitch will accept 2 inch hitch balls.

FIGURE 4

Vertical Position

Place

Log

Here

Base

CAUTION

Care must be taken when backing up

the Trailer; only back up the trailer on a

straight path. If the Trailer is allowed to turn

off the straight path while backing up, the Trailer

could jackknife, causing severe damage to the

trailer and to the towing vehicle.

07e