Page 13For technical questions, please call 1-800-444-3353.SKU 68333

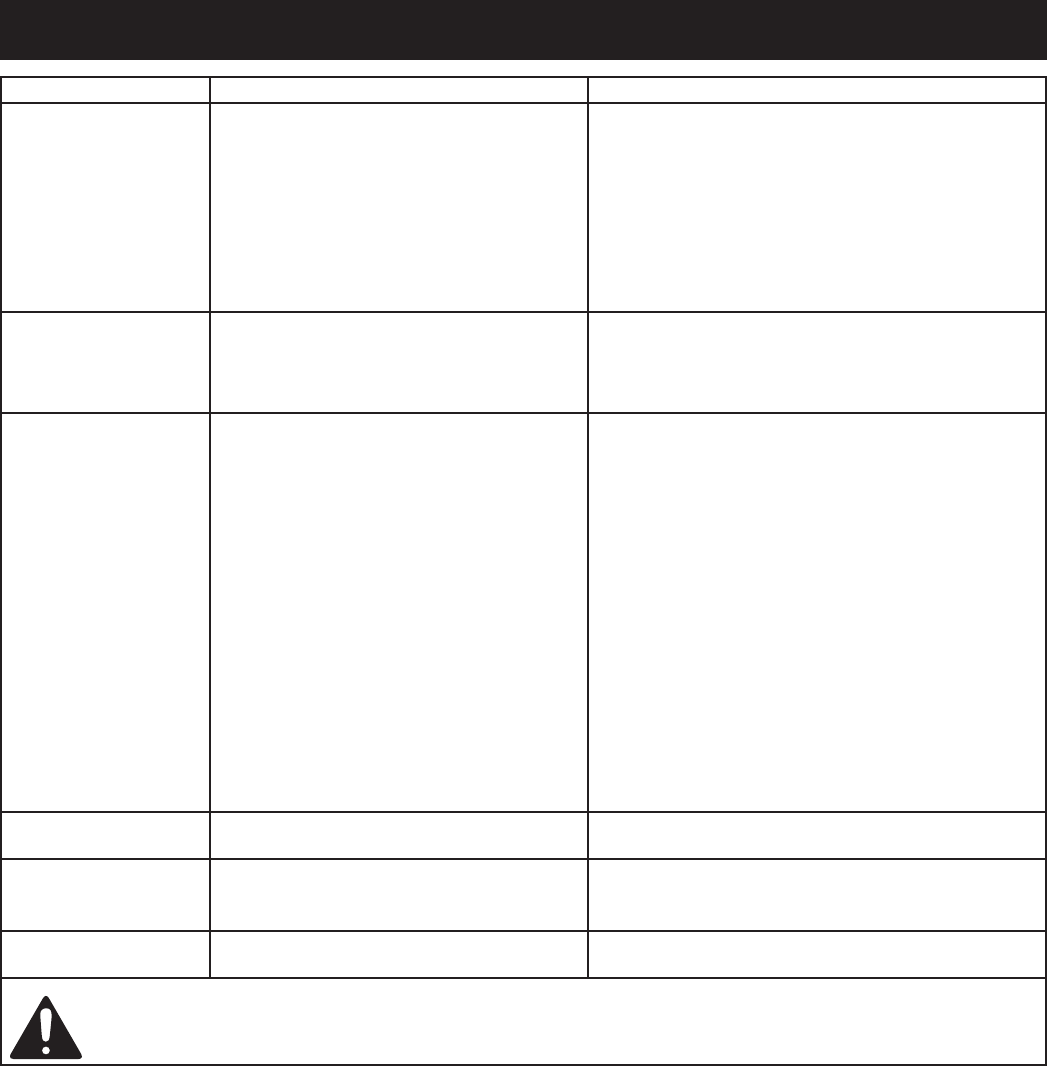

Problem Possible Causes Likely Solutions

Pressure Washer

will not start

1. Cord not connected.

2. No power at outlet.

3. GFCI circuit breaker tripped.

4. Internal damage or wear. (Carbon

brushes or switch, for example.)

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered,

turn off tool and check circuit breaker. If

breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

3. Press reset button on GFCI unit on cord.

4. Have a qualied technician service tool.

Pressure Washer

Stops suddenly

1. GFCI circuit breaker tripped.

2. Water leaking from housing.

1. Press reset button on GFCI unit on cord.

2. SHOCK HAZARD! IMMEDIATELY

discontinue use. Have the unit repaired by

a qualied technician before further use.

Output pressure

varies

1. Not enough water supply.

2. Air in water supply.

3. Water Inlet Filter is clogged.

4. Extension Nozzle not

attached to Spray Gun.

5. Nozzle is clogged.

6. Nozzle has mineral build up.

7. Garden hose is too long.

8. Internal valves or seals may

be worn or sticking.

1. Check water supply hose for kinks, leaks,

or blockage. Open faucet all the way.

2. Check that all connections are tight.

3. Remove Filter and clean.

4. Pressure is created by the Nozzle, not the

Spray Gun. Attach Extension Nozzle to unit.

5. Remove Nozzle and clean.

6. Remove Nozzle and clean with vinegar.

7. Recommended garden hose length is

20 to 50 feet, or 30 feet if using well

water. Shorten the length of the garden

hose if needed to increase pressure.

8. Have a qualied technician service tool.

Trigger does

not depress

Safety lock is still engaged. Press in on the release button on the bottom of

the Spray Gun Handle to release the Safety Lock.

Detergent will

not dispense

Incorrect detergent type. Check that the detergent is the recommended

type of detergent. Clean out dispenser and

replace with correct type if needed.

Performance

decreases over time

Clogged with mineral deposits. Clean unit with a de-mineralizing solution such

as vinegar or other aqueous acidic cleaner.

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power

supply before service.

Troubleshooting