22

2.1 LOCATION AND SUPPORT

2.1.1 GENERATOR LOCATION

The most desirable location for the generator set is

between the vehicle's main frame members. However,

this is seldom possible. Most units must be installed

on the side of the vehicle and are difficult to rein-

force.

Many recreational vehicles have been factory equipped

with an area for the generator set. Some vehicles may

even have a generator compartment provided by the

vehicle manufacturer.

Plan the generator location based on the following:

The generator set must be installed on a frame-•

work that is part of the recreational vehicle, as

outlined in the "Generator Support" section.

The location must provide an access opening •

that is large enough to permit generator removal

(unless the generator is to be removed from under-

neath the supporting framework).

The location must provide easy access to fre-•

quently serviced components, such as filters, oil

drains, spark plugs and other common mainte-

nance parts.

The location must provide sufficient room to allow •

minimum clearances as outlined in "Generator

Compartments". If sound insulation is to be used

on the compartment walls and ceiling, the mini-

mum recommended applies to the space between

the generator and such insulation.

The location must provide adequate cooling and •

ventilating airflow for the generator without a great

deal of work and expense.

If mounting the generator in an enclosed compart-•

ment, the base of the generator must rest flat on

the floor without any gaps.

When using a suspended mounting system, ensure •

the base of the generator is flush with the sur-

rounding bodywork. If the unit is mounted higher

in the structure, heated air may recirculate into the

generator causing it to overheat.

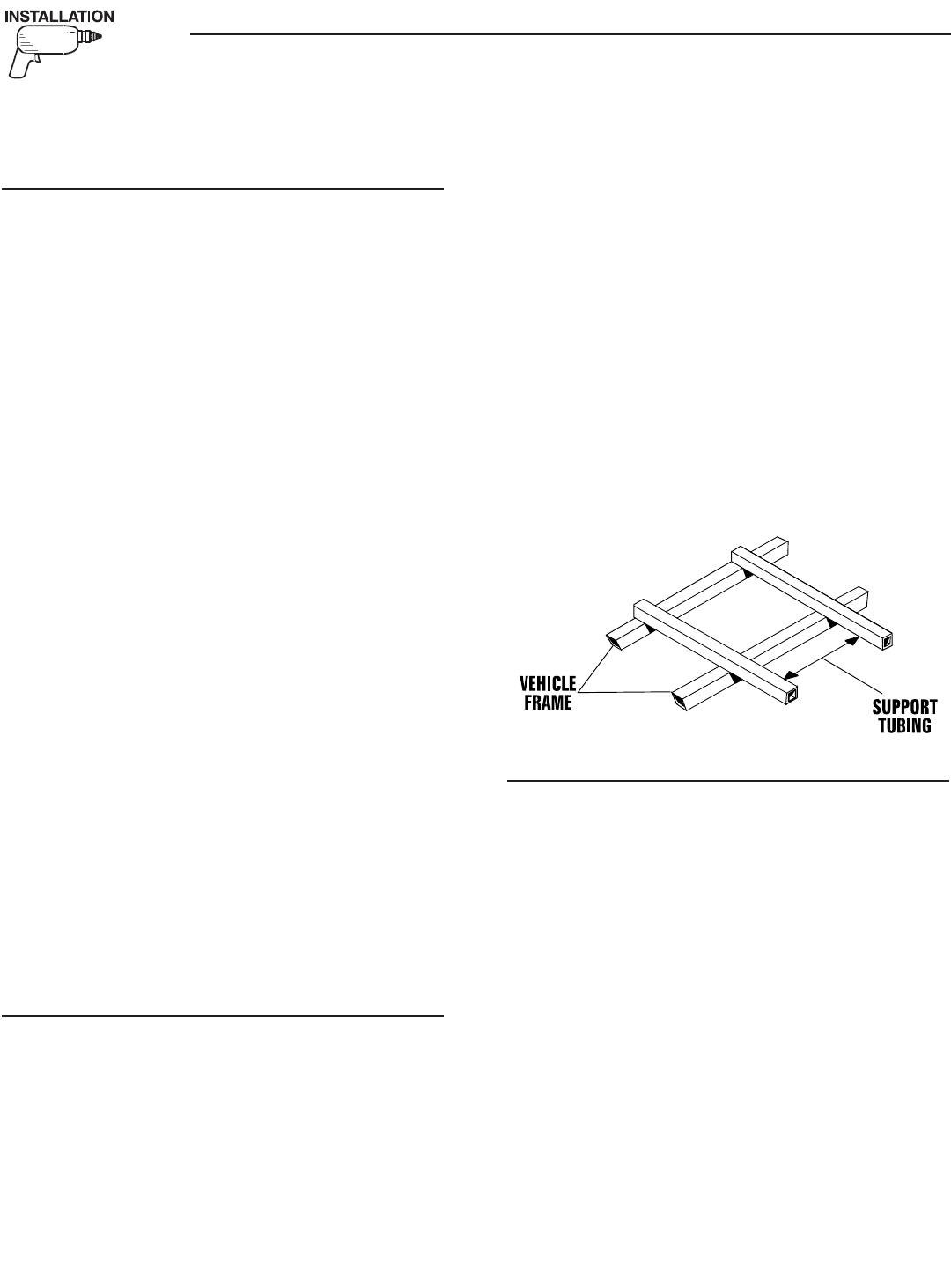

2.1.2 GENERATOR SUPPORT

The generator must be securely attached to a metal

framework that has been made part of the vehicle

frame structure by bolting or welding. The metal

framework on which the generator will rest and

which will restrain the generator set should consist

of at least two horizontal beams. These beams should

consist of (a) 1-1/2-inch square, 11-gauge steel tub-

ing OR (b) 1-1/2-inch, 11-gauge angle iron. A typical

supporting frame with horizontal support tubing, is

shown in Figure 2.1.

The generator can be installed so that it sits on top

of the horizontal support tubing if the vehicle design

permits. Another method is to suspend the genera-

tor below the horizontal support tubing by means of

suitable, structurally sound metal framework. The

following general rules apply:

Vehicle construction MUST be capable of support-•

ing the weight of the generator.

Whether the generator is mounted above the hori-•

zontal support tubing or suspended below the tub-

ing, the supporting frame used must be structur-

ally sound.

If the generator cannot be bolted directly to the •

supporting frame or support tubing, consider

using additional tubing, angle brackets or other

supports to give the supporting frame sufficient

strength.

Figure 2.1 – Typical Horizontal Support Frame

2.1.3 SUSPENDED MOUNTING

If the generator will be suspended below the hori-

zontal support tubing, the suspension method used

with the vehicle frame members must (a) be able to

support the weight of the generator AND (b) provide

sufficient restraint for the generator. One typical sus-

pended mounting system is shown in Figure 2.2. The

location of a suspended mounting system must be

carefully planned, keeping the following general rules

in mind:

Protect the generator against road splash and debris. •

Baffles or splash guards may be required to protect

certain areas of the generator. To make sure the gen-

erator is adequately protected, road test the installa-

tion through mud, water and slush.

The installer must make certain that the selected •

location will permit adequate cooling and ventilat-

ing airflow to be supplied.

Section 2 – Installation

Recreational Vehicle Generator