Service Transmission - 19

SERVICE TRANSMISSION

3. Remove dipstick cap (A). Wipe dipstick clean.

NOTE: NOTE: Do not tighten dipstick cap when checking oil level.

4. Insert dipstick into reservoir filler neck (B). Do not tighten cap.

5. Remove dipstick. Check oil level on dipstick. Oil level should be in

crosshatch area between ADD and FULL marks.

• If oil is low, add oil to bring oil level no higher than FULL mark on

dipstick.

• If oil is above FULL mark, drain oil to proper level.

6. Insert dipstick. Tighten cap.

Changing Hydraulic Oil and Filter

c

1. Park machine safely. (Refer to Parking Safely in the SAFETY section.)

2. Allow engine and hydraulic oil reservoir to cool.

c

3. Clean area around reservoir dipstick cap and oil filter.

4. Turn oil filter (A) counterclockwise to remove.

5. Allow hydraulic oil to drain into a drain pan with a capacity of at least

3.8L (1.0 gal).

6. Apply a film of clean hydraulic oil to gasket of new filter.

7. Install new filter. Turn filter clockwise until gasket makes contact with

mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

8. Remove dipstick cap from hydraulic reservoir filler neck.

c

NOTE: Dry fill capacity for hydraulic system is 3.1L (3.3 qt.).

10. Fill oil reservoir with approximately 1.9L (2 qt.) of oil.

11. Insert dipstick. Tighten cap.

12. Start engine.

13. Move throttle lever to 1/2 to 2/3 position.

14. Unlock park brake.

c

15. Cycle motion control levers forward and rearward several times.

Check for leaks around filter.

16. Stop engine. Check oil level. Add oil as necessary to bring oil level to

FULL mark on dipstick.

Cleaning Hydraulic Oil Pump Cooling Fins

c

1. Park machine safely. (See Parking Safely in the SAFETY section.)

c

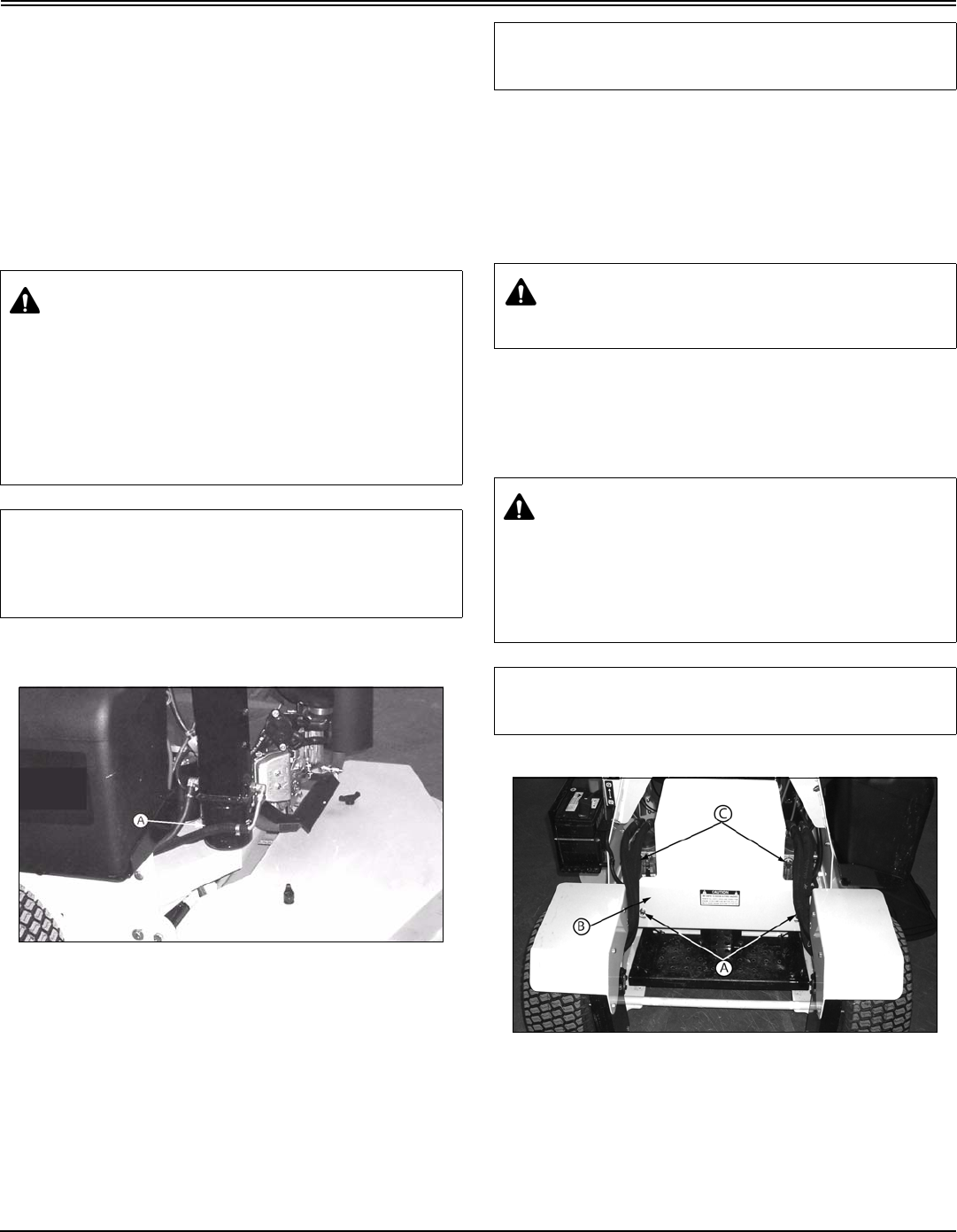

2. Remove four cap screws (A).

3. Remove rear shield (B) to access hydraulic pumps (C).

4. Clean hydraulic oil cooling fins on each hydraulic pump with a rag,

brush or compressed air.

5. Clean area around hydraulic pumps and frame.

CAUTION: Avoid injury! Escaping fluid under pressure can

penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic or other

lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and

body from high pressure fluids.

Use caution when filling and draining hydraulic oil. During

periods of machine operation the hydraulic oil reservoir can

get hot. Allow engine and oil reservoir to cool before

servicing.

IMPORTANT: Avoid Damage! Contamination of hydraulic fluid

could cause transmission damage or failure. Do not open oil

reservoir cap unless absolutely necessary.

Severe or unusual conditions may require a more frequent

service interval.

IMPORTANT: Avoid Damage! Do not add oil beyond FULL mark.

Oil capacity after draining may be less than dry fill capacity.

Check oil level before filling completely.

CAUTION: Avoid injury! Help prevent serious bodily injury.

Remain alert to other people and the surroundings when

operating the machine.

CAUTION: Avoid injury! Compressed air can cause debris to

fly a long distance.

• Clear work area of bystanders.

• Wear eye protection when using compressed air for

cleaning purposes.

• Reduce compressed air pressure to 210 kPa (30 psi).

IMPORTANT: Avoid Damage! To ensure proper cooling, keep the

cooling fins clean at all times. Operating the machine with

obstructed cooling fins could cause damage due to overheating.