Service Miscellaneous - 33

SERVICE MISCELLANEOUS

Checking Tire Pressure

c

1. Check tires for damage.

2. Check tire pressure with an accurate gauge.

3. Add air, if necessary:

c

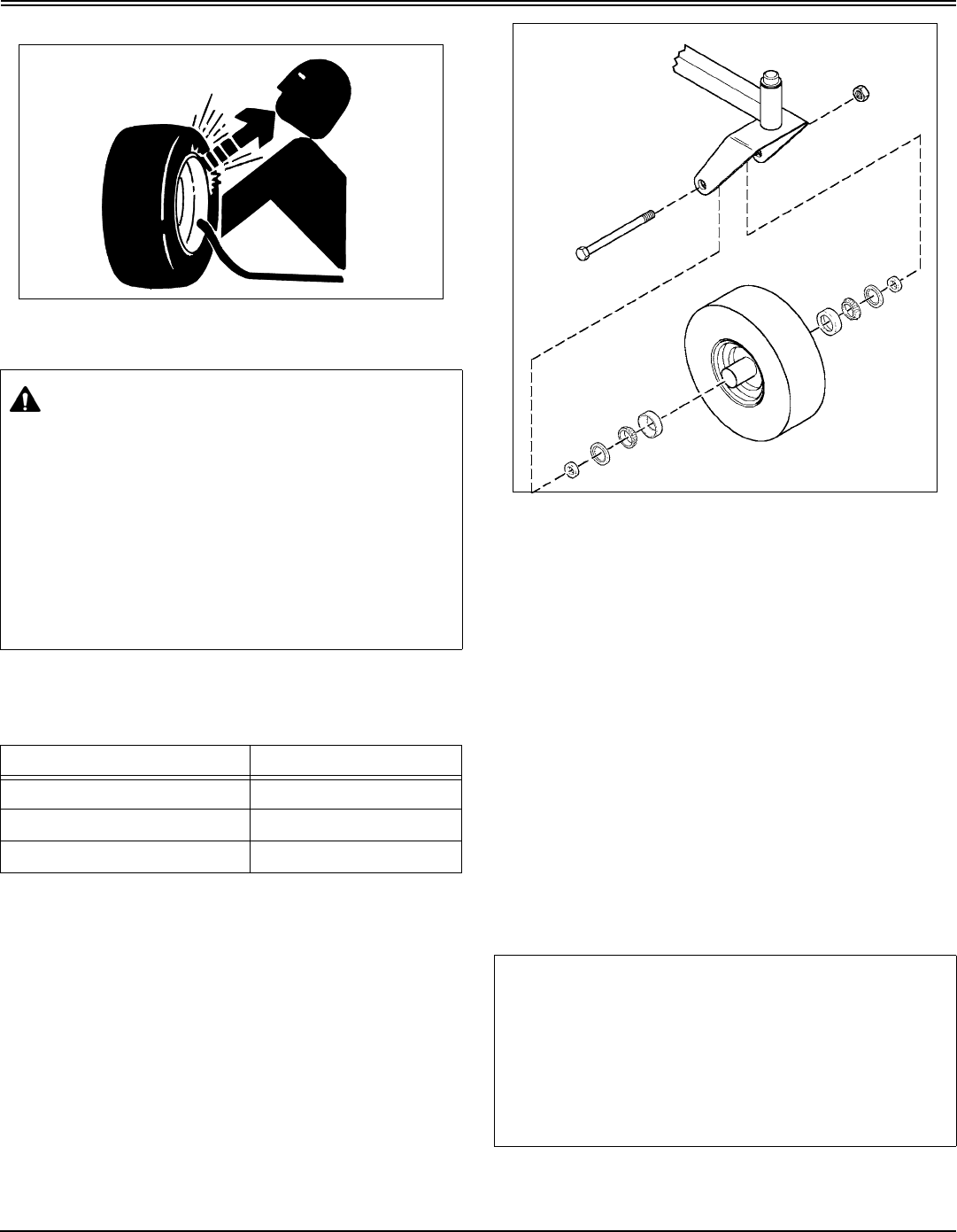

Servicing Caster Wheel Roller Bearings

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Raise and securely support front of machine.

c

3. Remove locknut (A), cap screw (B), two seal spacers (C) and wheel

assembly (D).

NOTE: Bearing races (G) are pressed in place and will be damaged

when removed. Do not remove bearing races (G) unless they need to

be replaced with new.

4. Remove seals (E), bearings (F) and if needed, bearing races (G) from

wheel.

5. Clean and inspect bearings (F) and races (G). Replace as needed.

6. Repack bearings with clean grease.

7. Install bearings (F) and races (G) (if removed), and new seals (E).

8. Install wheel assembly (D), two seal spacers (C), cap screw (B) and

locknut (A).

9. Use a grease gun to fill hub until grease just appears at one of the seals

(E).

10. Lower machine.

Cleaning and Repairing Plastic Surfaces

Your authorized dealer has the professional materials needed to properly

remove surface scratches from any plastic surfaces, do not attempt to

paint over marks or scratches in plastic parts.

c

1. Wash surface with clean water and a mild liquid automotive washing

soap.

CAUTION: Avoid injury! Explosive separation of tire and rim

parts is possible when they are serviced incorrectly:

Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

Do not inflate the tires above the recommended pressure.

Do not weld or heat a wheel and tire assembly. Heat can

cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform the

wheel.

Do not stand in front or over the tire assembly when

inflating. Use a clip-on chuck and extension hose long

enough to allow you to stand to one side.

Tire Size Pressure

Front: 13 x 5-6 110–138 kPa (16–20 psi)

Rear: 20 x 10-8 69–97 kPa (10–14 psi)

Rear: 20 x5.3C 69–97 kPa (10–14 psi)

IMPORTANT: Avoid Damage! Improper care of machine plastic

surfaces can damage that surface:

Do not wipe plastic surfaces when they are dry. Dry wiping will

result in minor surface scratches.

Use a soft, clean cloth (bath towel, diaper, automotive mitt).

Do not use abrasive materials, such as polishing compounds, on

plastic surfaces.

Do not spray insect repellent near machine.