Service Miscellaneous - 32

SERVICE MISCELLANEOUS

c

Fill fuel tank at the end of each day’s operation to prevent condensation

and freezing during cold weather.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Allow engine to cool.

3. Remove any trash from area around fuel tank cap.

4. Remove fuel tank cap slowly to allow any pressure built up in tank to

escape.

5. Fill fuel tank only to bottom of filler neck.

6. Install fuel tank cap.

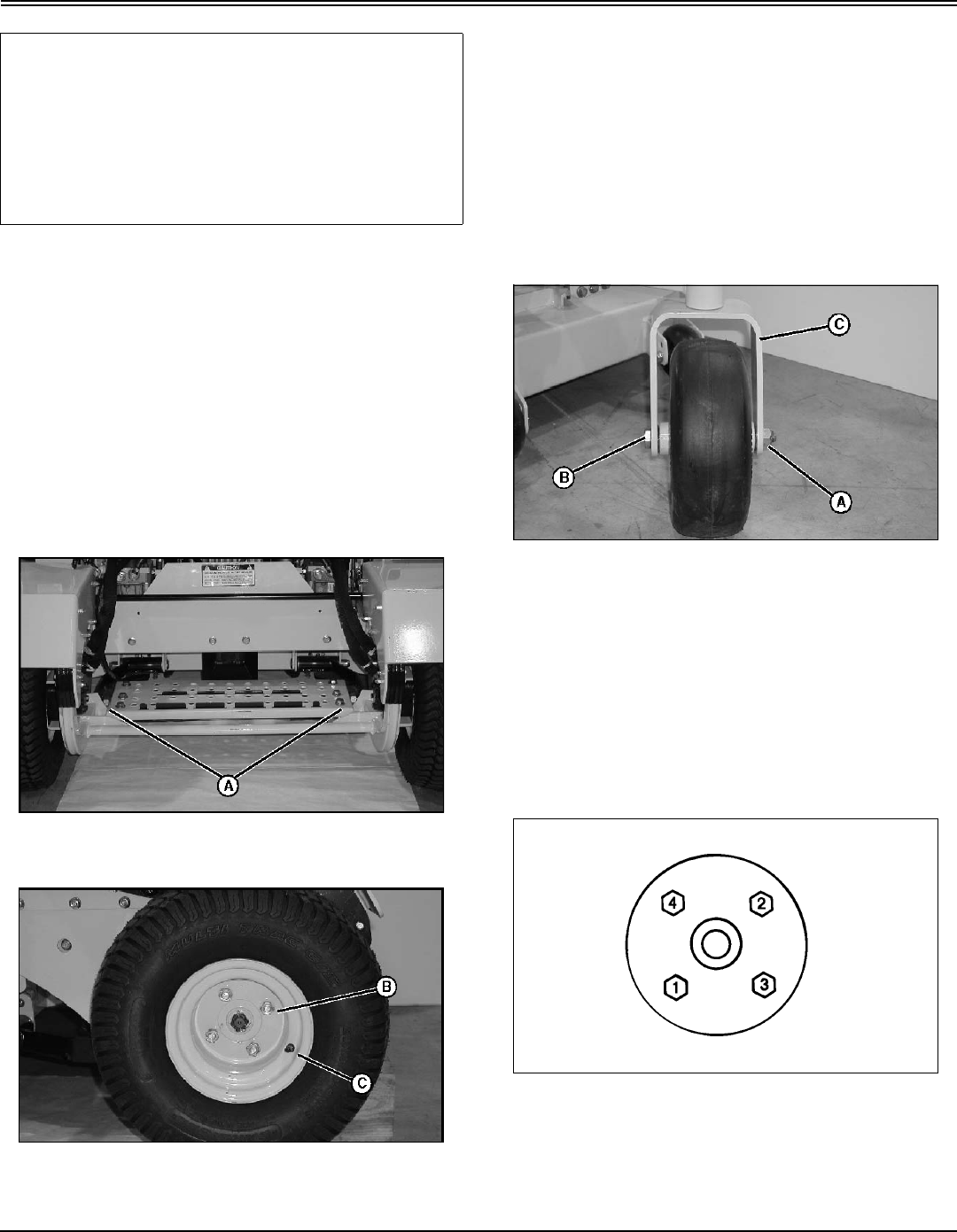

Removing and Installing Rear Drive Wheels

Removing:

1. Park machine safely. (Refer to Parking Safely in the SAFETY section.)

c

2. Lift machine with a safe lifting device centered under tire support frame

(A) on the side where tire is being removed.

c

3. Remove wheel nuts (B).

4. Remove wheel.

Installing:

1. Install wheel with valve stem (C) facing out.

2. Install and tighten wheel nuts alternately until recommended torque

value is reached.

• Tighten nuts to 102 N•m (75 lb-ft).

3. Lower machine.

Removing and Installing Front Caster Wheels

Removing:

1. Park machine safely. (Refer to Parking Safely in the SAFETY section.)

2. Lift front of machine with a safe lifting device.

c

3. Remove nut (A) and wheel cap screw (B).

4. Remove wheel and spacers from yoke assembly (C).

Installing:

1. Install replacement wheel and original spacers.

2. Install wheel cap screw (B) and nut (A).

3. Tighten nut until wheel develops slight rolling resistance.

4. Lower machine.

Tightening Rear Drive Wheel Hardware

1. Tighten rear wheel nuts to 102 N•m (75 lb-ft).

c

2. Tighten wheel nuts in numbered sequence shown for safe wheel

installation. Tighten alternately until recommended torque value is

reached.

Important: Avoid damage! Dirt and water in fuel can cause engine

damage:

• Clean dirt and debris from the fuel tank opening.

• Use clean, fresh, stabilized fuel.

• Fill the fuel tank at the end of each day’s operation to keep

condensation out of the fuel tank.

Use a non-metallic funnel with a plastic mesh strainer when filling

the fuel tank or container.