Specifications - 49

SPECIFICATIONS

NOTE: Using a tapered drift will aid in the alignment of mounting

holes and ease installation of cap screws.

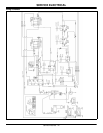

5.Lay ROPS on the ground, slide it up to the bumper and align the

appropriate hole in the ROPS flange with the lower rear mounting holes in

the machine frame and bumper. Install an M10 cap screw, removed

earlier, through the hole from the inside and secure loosely with an M10

locknut (F).

6. Remove cap screw (C).

NOTE: Take care when raising ROPS to avoid damaging paint on

bumper.

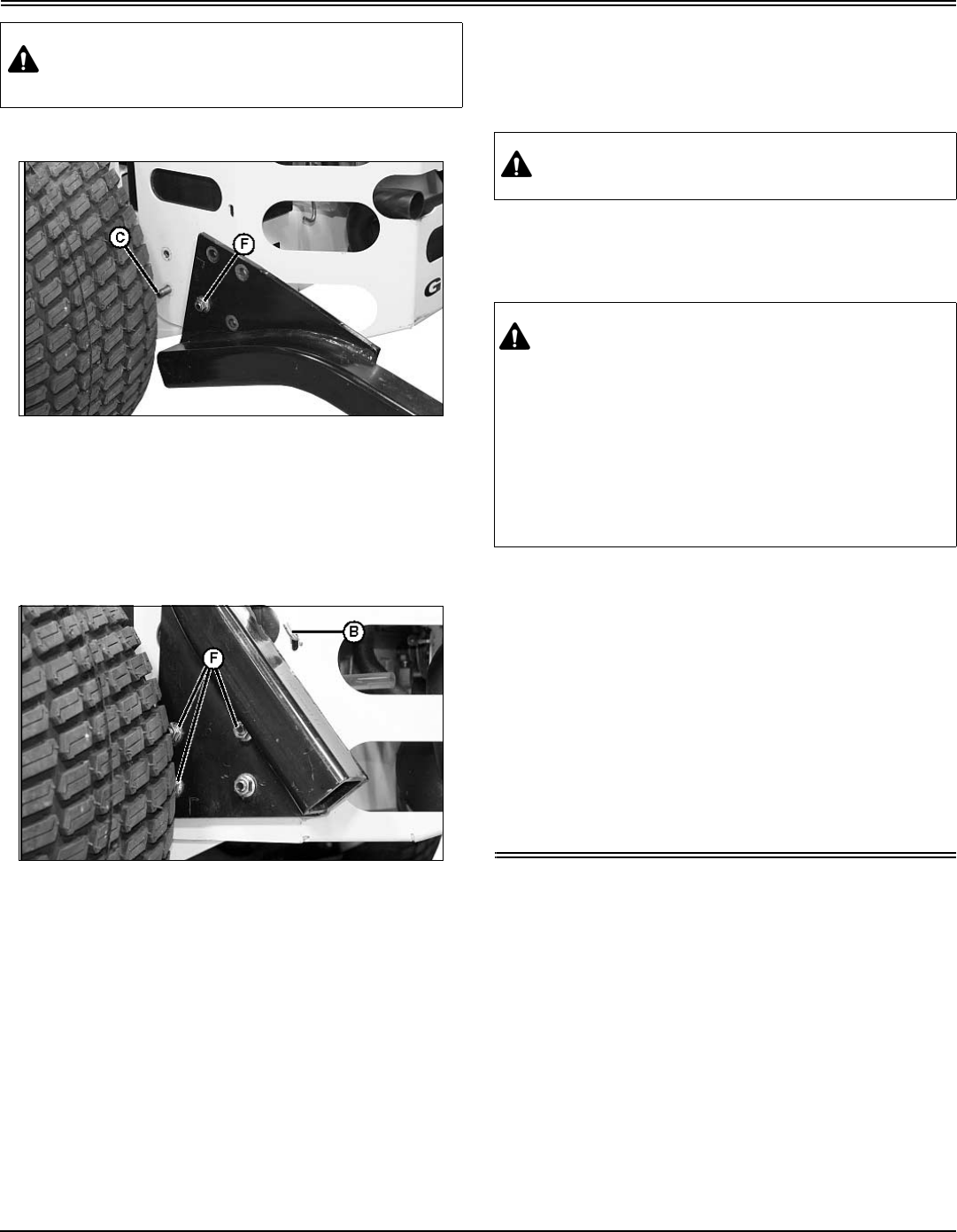

7.Using the lower rear bolts as a pivot, raise ROPS to the vertical position,

and install remaining cap screws and locknuts (F) on each side. Tighten all

ROPS mounting hardware to 80 N•m (59 lb-ft).

8.Engage hooked end (B) of rear battery hold-down rod in slot in bumper

and tighten nut to secure.

Lubricate Machine

Lubricate all moving parts before operating the machine. See Lubrication

Points in the Service Lubrication section.

Check Mower Deck Level

The mower deck is assembled and adjusted at the factory. After machine

is completely assembled, check the mower front-to-rear and side-to-side

deck level.

Check Safety System

For a complete checkout procedure of the safety interlock system, see

Testing the Safety Interlock System in the Operating section.

Initial Adjustments

1.Check free-wheel valves on both pump assemblies to make sure that

the valves are closed. Tighten valves to 108-163 N•m (80-120 lb-ft).

2.Raise the rear of the machine until the drive wheels are off the ground.

Support the machine with jackstands.

3.Start and run the engine until it reaches normal operating temperature.

4.Move control levers to the forward position and observe drive wheel

rotation; the drive wheels should rotate in the correct direction.

5.Move the control levers to the reverse position and observe drive wheel

rotation; the drive wheels should rotate in the correct direction.

6.Move PTO clutch switch to on position; mower clutch should engage.

Run blades for several minutes.

7.Move PTO clutch switch to off position and shut the engine off.

8.Check all belts for proper tension.

9.Start the engine and test drive the machine in an open area. Drive the

machine forward; if the machine drifts to the right or left, adjust the

transmission control linkage.

Specifications

Engine

NOTE: See engine manufacturer’s owner’s manual provided with

your machine for engine specifications.

Battery

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt

CCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .340 amp

Reserve Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 minutes

BCI Group Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Tires

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 x 5.0-6

Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 x 9.50-12

Inflation Front (Maximum) . . . . . . . . . . . . . . . . . . 110-138 kPa (16-20 psi)

CAUTION: Avoid injury! Machine component is heavy. Use a

safe lifting device or get an assistant to help lift and hold

component into place for installation.

CAUTION: Avoid injury! Clear area of all bystanders before

performing this service procedure.

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

•Move the machine to an outside area before running the

engine.

•Do not run an engine in an enclosed area without

adequate ventilation.

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.