Service Mower - 38

SERVICE MOWER

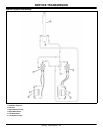

4.Loosen jam nut (A).

5.Check the mower deck drive belt (B) tension. The belt should deflect a

maximum of 13 mm (1/2 in.) when a force of 4.5 kg (10 lb) is applied to the

center of the longest span.

When properly adjusted, there would be approximately a 2 mm (1/16 in.)

gap between the spring coils.

• To increase belt tension: Turn nut (C) clockwise.

• To decrease belt tension: Turn nut (C) counterclockwise.

6.Tighten jam nut (A).

7.Lower foot platform.

Removing and Installing Mower Deck Drive Belt

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Raise foot platform.

3.Remove mower deck drive belt covers.

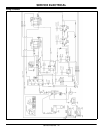

4.Release mower deck drive belt tension by turning the tension adjuster

nut (A) counterclockwise.

5.Remove mower deck drive belt (B).

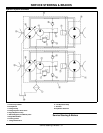

A- PTO Clutch Sheave

B- Mower Deck Drive Belt

C- Tension Idler Sheave

D- Left Spindle Sheave

E- Center Spindle Sheave

F- Idler Sheave

G- Right Spindle Sheave

H- Idler Sheave

6.Install new mower deck drive belt (B) as shown.

7.Adjust belt tension.

8.Install mower deck drive belt covers.

9.Lower foot platform.

Checking and Replacing Mower Blades

CAUTION: Avoid injury! Fingers and hands can be pinched or

crushed. Keeps hands clear of sheave and belt pinch points

when servicing belt.

CAUTION: Avoid injury! Do not work near raised mower deck

unless it is safely supported.

•Mower blades are sharp. Wrap blades or wear gloves

when servicing.

•Before performing any service function, wait for all

moving parts to stop turning.

•Disconnect battery or remove spark plug wire before

making repairs.