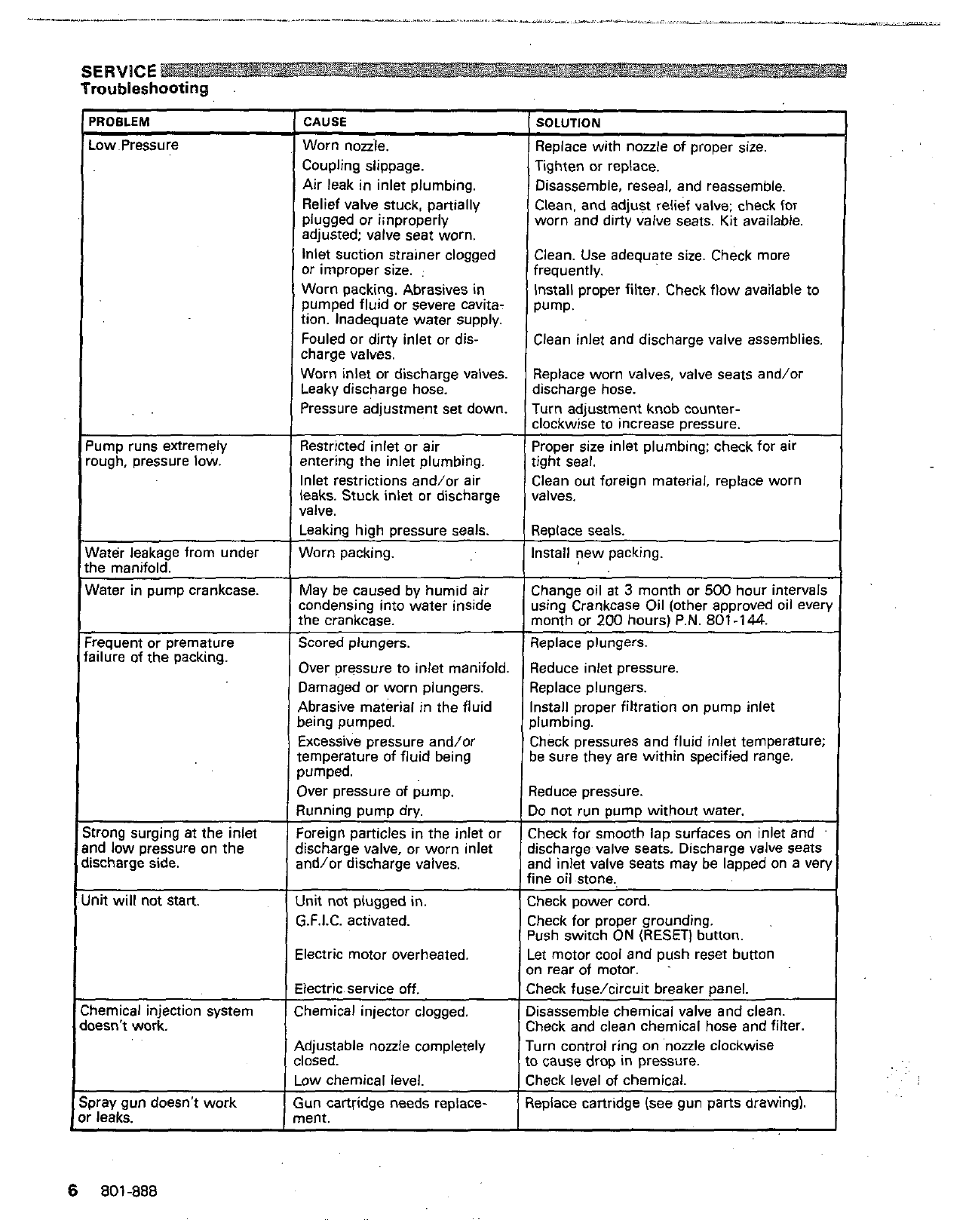

SERVICE

Troubleshooting

PROBLEM

Low.Pressure

rump runs extremely

rough, pressure low.

iNater leakage from under

:he manifold.

iNater

in

pump crankcase.

Zrequent or premature

'ailure of the packing.

jtrong surging at the inlet

Ind low pressure on the

lischarge side.

hit

will not start.

:hemica1 injection system

oesn't work.

r leaks.

pray gun doesn't work

CAUSE

Worn nozzle.

Coupling slippage.

Air leak

in

inlet plumbing.

Relief valve stuck, partially

adjusted; valve seat worn.

plugged or improperly

Inlet suction strainer clogged

or improper size.

:

Worn packing. Abrasives

in

tion. Inadequate water supply.

pumped fluid or severe cavita:

charge valves.

Fouled or dirty inlet or dis-

Worn inlet or discharge valves.

Leaky discharge hose.

Pressure adjustment set down.

entering the inlet plumbing.

Restricted inlet or air

leaks. Stuck inlet or discharge

Inlet restrictions and/or air

valve.

Leaking high pressure seals.

Worn packing.

May be caused by humid

air

condensing into water inside

the crankcase.

Scored plungers.

Over pressure to inlet manifold.

Damaged or worn plungers.

4brasive material

in

the fluid

3eing pumped.

I

Excessive pressure and/or

:emperatwe of fluid being

Jumped.

3ver pressure

of

pump.

SOLUTION

Replace with nozzle of proper size.

Tighten or replace.

Disassemble, reseal, and reassemble.

Clean, and adjust relief valve; check for

worn and dirty valve seats.

Kit

available.

Clean. Use adequate size. Check more

frequently.

Install proper filter. Check flow available to

pump.

Clean inlet and discharge valve assemblies.

Replace worn valves, valve seats and/or

discharge hose.

rurn adjustment knob counter-

:lockwise to increase pressure.

'roper size inlet plumbing: check for air

:ight seal.

:lean out foreign material, replace worn

Ialves.

7eplace seals.

nstall new packing.

:hange oil

at

3

month or

500

hour intervals

)sing Crankcase Oil (other approved oil every

nonth or

200

hours)

P.N.

801-144.

leplace plungers

leduce inlet pressure.

leplace plungers.

nstall proper filtration

on

pump inlet

Ilumbing.

:heck pressures and fluid inlet temperature;

le sure they are within specified range.

leduce pressure.

7unning pump dry.

Do

not run pump without water.

:oreign particles

in

the inlet or

Check for smooth lap surfaces on inlet and

lischarge valve,

or

worn inlet

discharge valve seats. Discharge valve seats

and/or discharge valves.

and inlet valve seats may be lapped

on

a very

Jnit

not plugged

in.

Check power cord.

j.F.1.C. activated.

Check for proper grounding.

ilectric motor overheated.

Let motor cool

and

push reset button

ilectric service

off.

Check fuse/circuit breaker panel.

:hemica1 injector clogged. Disassemble chemical valve and clean.

\djustable nozzle completely

Turn control ring

on

nozzle clockwise

losed. to cause drop

in

pressure.

.ow chemical level.

Check level of chemical.

iun

cartridge needs replace- Replace cartridge (see gun parts drawing).

fine oil stone.,

Push switch

ON

(RESET)

button.

on

rear

of

motor.

,

Check and clean chemical hose and filter.

6

801-888