Unloader

Remove the locknut

(67).

adjusting nut

(68)

and spring

washers

(71).

Remove bolts

(511

and separate the upper and lower

casings

(48

and

49).

All other parts can then be freely

removed.

To replace the cup and back-up ring

(46

and

47):

a.

Cut

through the old cup and back-up ring and

b.

Grip the shaft sleeve

(69)

in

a

vise equipped with jaw

remove them from the valve stem.

c. Slowly heat the end of the valve stem and piston

165)

protectors.

with

a

propane torch. When the assembly is hot

enough, (about

250"

F

[120"

C]) the piston can be

easily screwed

off

the valve stem by firmly gripping

with

a pair of pliers.

d. After the assembly cools, mount a new back-up ring

and cup on the piston.

e. Before replacing the piston, put a few drops of

locking compound on the valve stem threads.

disassembled.

Items

69

and

70

are supplied as

a

unit and should not be

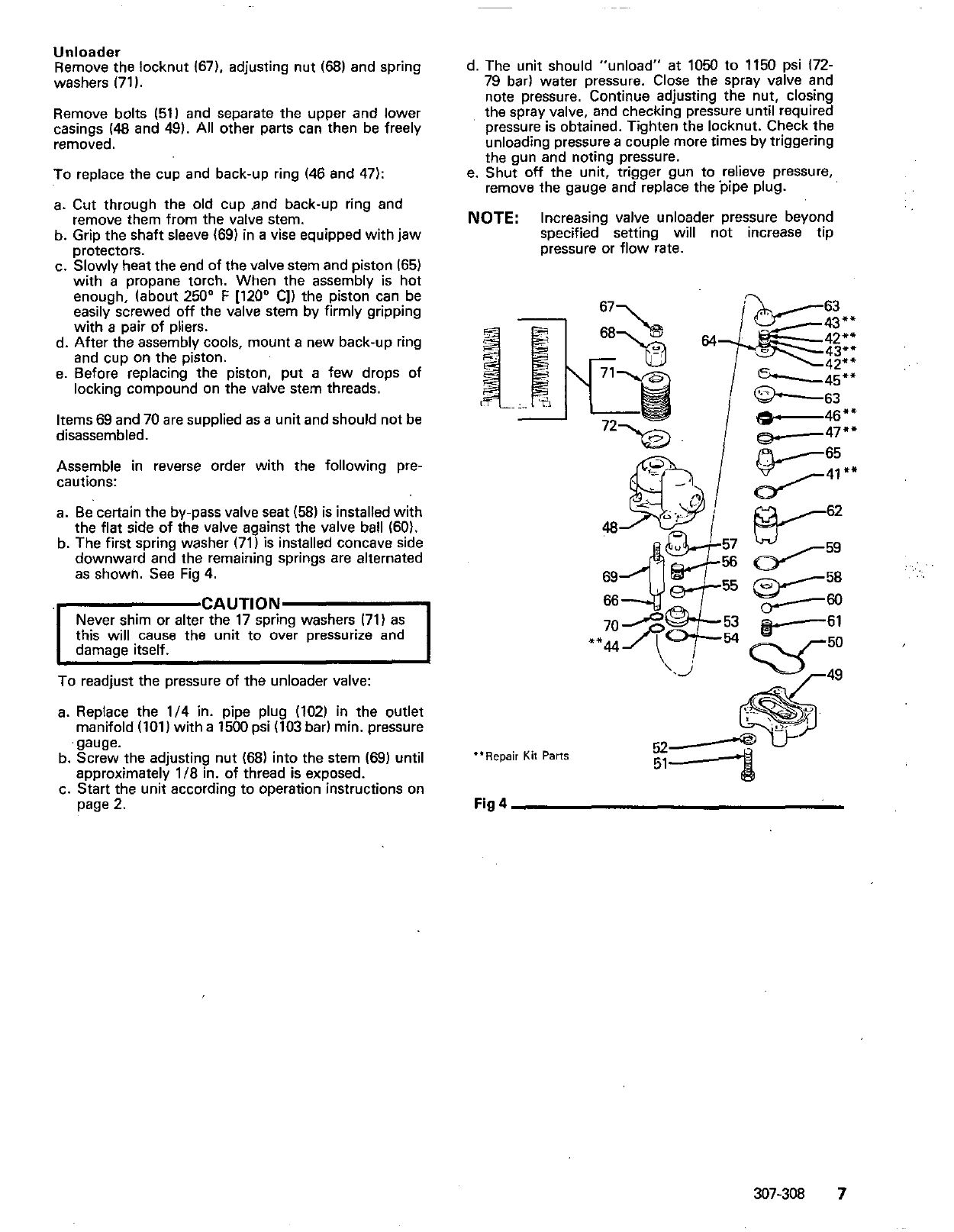

Assemble in reverse order with the following pre-

cautions:

a. Be certain the by-pass valve seat

(58)

is installed with

b. The first spring washer

(71)

is installed concave side

the flat side of the valve against the valve

ball

(60).

downward and the remaining springs are alternated

as shown. See Fig

4.

'ICAUT'ON1

Never shim or alter the

17

spring washers

171)

as

this will cause the unit to over pressurize and

damaae itself.

To readjust the pressure of the unloader valve:

a. Replace the

1/4

in. pipe plug

(102)

in

the outlet

manifold

(101)

with a

1500

psi

(103

bar) min. pressure

b. Screw the adjusting nut

(68)

into the stem

(69)

until

gauge.

c. Start the unit according to operation instructions on

approximately

118

in. of thread is exposed.

page

2.

~~ ~

d. The unit should "unload" at

1050

to

1150

psi

(72-

79

bar) water pressure. Close the spray valve and

note pressure. Continue adjusting the nut, closing

the spray valve, and checking pressure until required

pressure is obtained. Tighten the locknut. Check the

the gun and noting pressure.

unloading pressure a couple more times by triggering

e. Shut

off

the unit, trigger gun to,relieve pressure,

remove the gauge and replace the pipe plug.

NOTE:

Increasing valve unloader pressure beyond

specified setting will not increase tlp

pressure or flow rate.

. ...

..

"Repair

Kit

Parts

52

51

307-308

7