-

Accompanied

By

Smooth

Decreased Delivery

Operation

Excessive Leakage

suction piping (suction valve

Plugged or constricted

not fully open);

Collapsed suction hose.

Worn valve seats.

Slipping couplers.

Worn piston cups;

Loose

piston bolts;

Damaged O-rings;

Cracked ceramic liners;

Faulty gaskets;

Loose

valve caps;

Loose cylinder head bolts or

malfitted heads.

Examine the water

in

the barrel or tank for air

bubbles while the pump is discharging. If no

bubbles are seen and the discharge has actually

decreased, look for plug-ups, worn valve seats, or

collapsed suction hose. If bubbles are seen, look

for air leaks in the suction piping or for air leaking

past the piston cups. These leaks are hard to find

because they are leaking "in" rather than

"out".

However, if arrangements are made to put

pressure into the suction

piping

or if new cups

smooth out the pump operation, the problem is

solved

Look for worn or pitted valve seats. Replace if

necessary.

eccentric roller bearing and yoke pads with a

Measure clearance between outer surface or

feeler gauge. This should not exceed

0.010

inch

(0.2%

mm).

NOTE:

Worn yoke pads will give

a

very noisy

operation. Replace the yoke or pads if

necessary.

cup

will

not leak severely until

it

is torn. The piston

Examine pistons and cups for wear. Generally a

should not be more than

0.020

in.

10.508

mm)

out

of round.

Tighten

loose

piston bolts, cylinder head bolts and

80-grit sandpaper which is laid on

a

flat surface.

valve caps. Remove head and sand flat part on

Check O-rings and gaskets for wear or breaks.

ceramic liners for cracks. Replace all damaged

Remove cylinder heads and blocks to examine

parts.

SERVICE

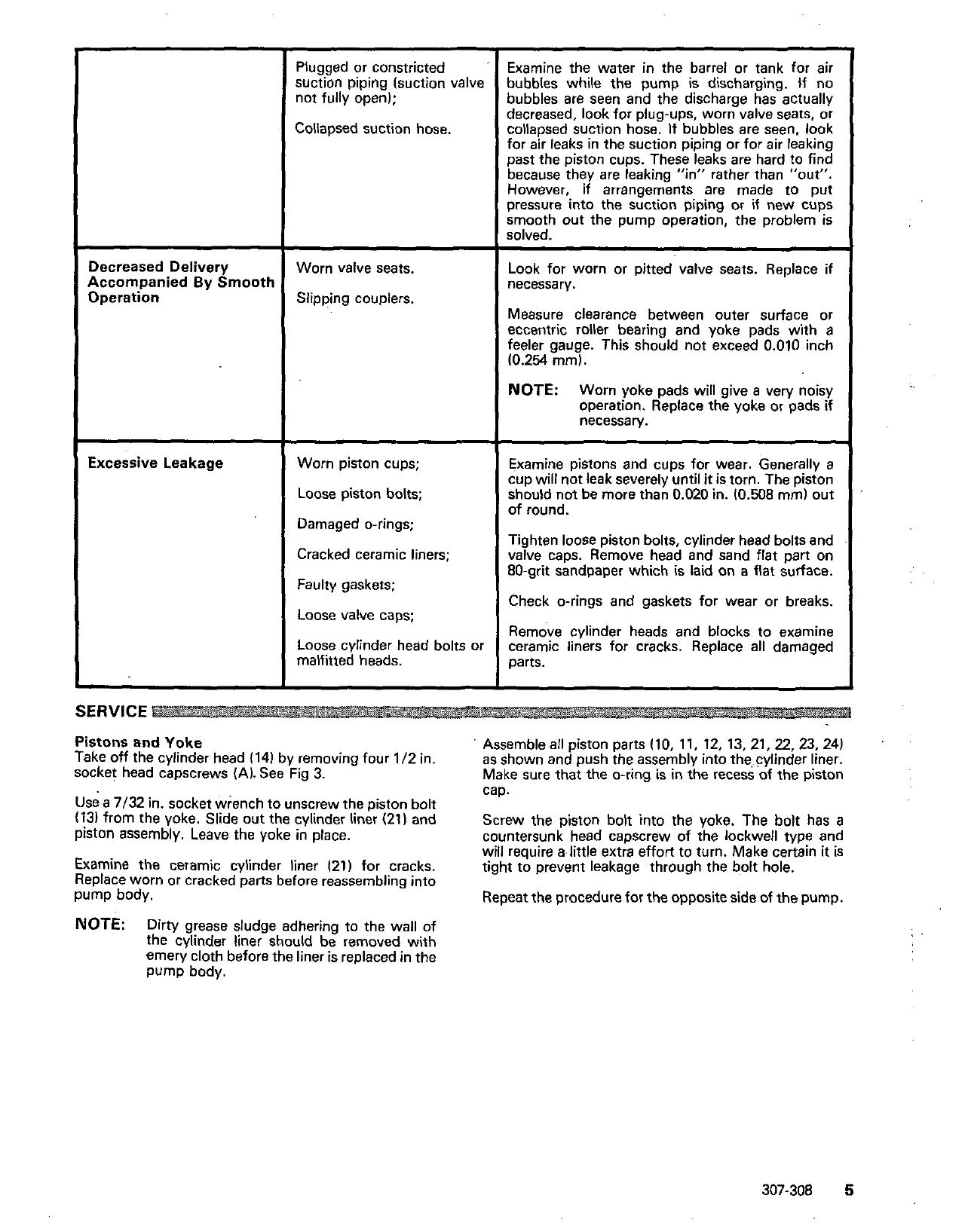

Pistons and Yoke

Take

off

the cylinder head

(14)

by removing four 112 in.

Assembleall piston parts (10. 11.

12.

13, 21,

22,

23,

24)

'

'

as shown and push the assembly into the. cylinder liner.

socket head capscrews (A).

See

Fig 3. Make sure that the O-ring is

in

the recess of the piston

cap.

(13) from the yoke. Slide out the cylinder liner

(21)

and

Use

a

7/32 in. socket wrench to unscrew the piston bolt

Screw the piston bolt into the yoke.

The

bolt has

a

piston assembly. Leave

the

yoke

in

place.

will require a-little extra effort to turn. Make certain

it

is

countersunk head capscrew of the lockwell type and

Examine the ceramic cylinder liner (21) for cracks. tight to prevent leakage through the b.olt hole.

Replace worn or cracked parts before reassembling into

pump body.

NOTE:

Dirty grease sludge adhering

to

the wall of

the cylinder liner should be removed with

emery cloth before the liner is replaced in the

pump body.

Repeat the procedure for the opposite side

of

the pump.

307-308 5