Lubrication

Change the engine oil after every 50 hours of operation.

every

EO

hours of operation. Remove excess grease

Grease the pump's front bearing and main bearing after

from the front bearing cavity. Replace the pump front

cover before starting the engine.

oil every 500 hours, but sooner if oil becomes dirty; The

Lubricate the gear reduction unit regularly: change the

engine manufacturer recommends using "For Service

operation, and S.A.E.

20

for winter operation.

SD

or

SE'

S.A.E. 30 oil for spring, summer, or fall

unit and loosen cover.

Drain oil with engine warm. Place pan under reduction

NOTE:

Once a year, remove engine cover com-

pletely and flush out inside of housing with

kerosene.

DO

NOT

use

gasoline for

cleaning.

Remove filler and level plugs. Pour oil through vent hole

of filler plug until

it

runs

out

through level hole. About

3/8

pint

(177

cc) is required. Replace oil level plug and

vented filler plug.

When changing engine crankcase oil, check reduction

unit and add oil if necessary

to

maintain proper level.

NOTE:

Vented filler plug should be removed

periodically and vent hole thoroughly

cleaned. Ventilation is necessary to eliminate

pressure build-up causing oil leaks, and

to

prevent condensation from forming in the

housing.

Follow the maintenance procedures for the engine

outlined in the accompanymg instructions.

The accumulator

(EO)

which acts as a buffer

to

smooth

pump strokes, is nitrogen. charged and must be re-

charged generally every

6

to

12

months to

540-660

psi

location for recharging.

(37-45 bar). Contact a local fire extinguisher servlce

Never remove stem valve from accumulator, or

check its pressure wlth a standard tire pressure

Never try

to

recharge accumulator with ordinary

car service station equipment.

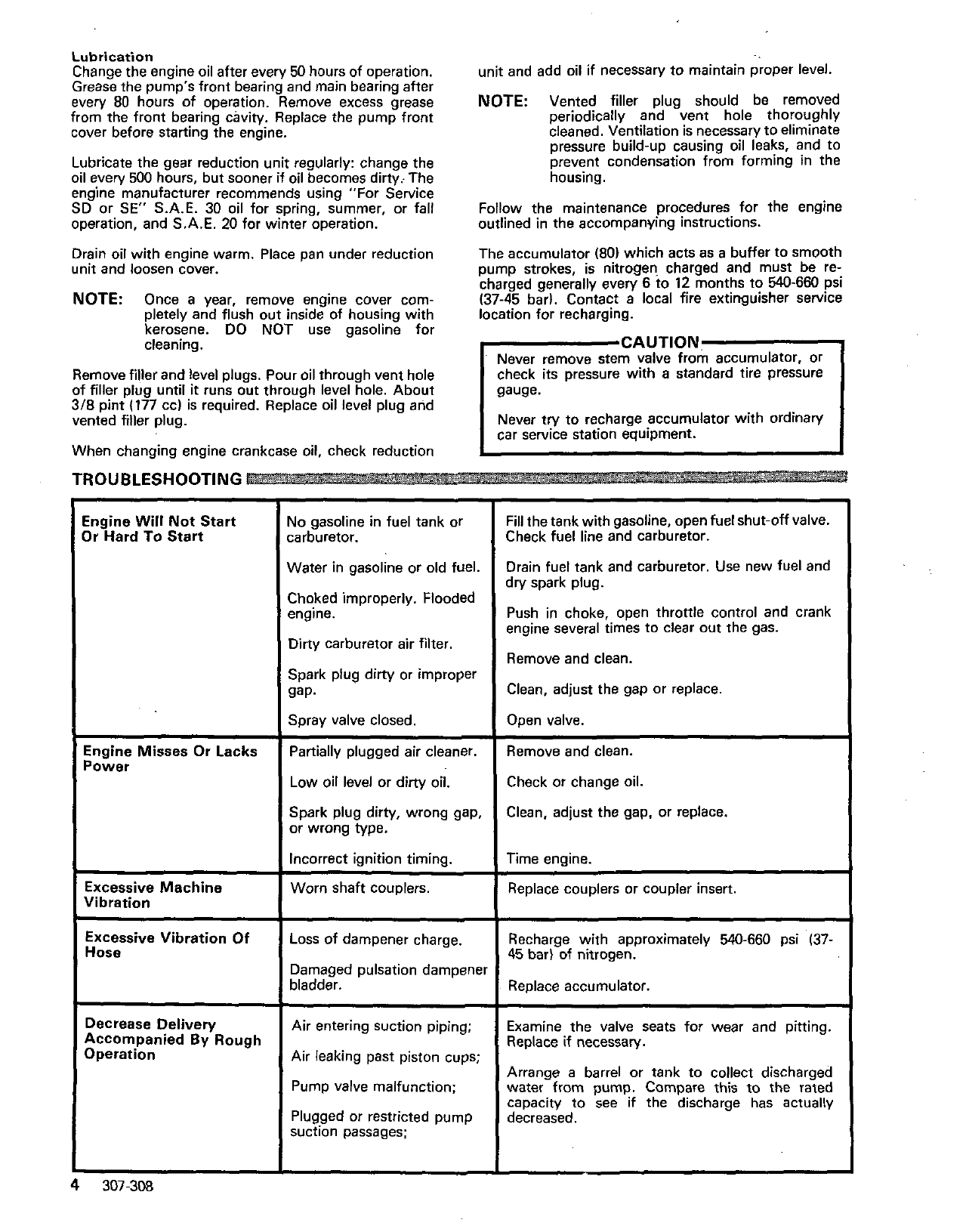

TROUBLESHOOTING

Engine Will Not Start

Or Hard

To

Start

No

gasoline in fuel tank or

carburetor.

Water in gasoline or old fuel.

Choked improperly. Flooded

engine.

Dirty carburetor air filter.

Spark plug dirty or improper

gap.

Spray valve closed.

I

Engine Misses Or Lacks

Power

Partially plugged air cleaner.

Low oil level or dirty oil.

Spark plug dirty, wrong gap,

or wrong

type.

Incorrect ignition timing.

I

.

Excessive Machine Worn shaft couplers.

Vibration

Excessive Vibration

Of

Hose

Loss

of dampener charge.

bladder.

Damaged pulsation dampener

Accompanied By Rough

Decrease Delivery

Air leaking past piston cups;

Operation

Air entering suction piping;

Pump valve malfunction:

suction passages:

Plugged

or

restricted pump

Fill the tank with gasoline, open

fuel shut-off valve.

Check fuel line and carburetor.

Drain fuel tank and carburetor. Use new fuel and

dry spark plug.

engine several times

to

clear

out

the gas.

Push in choke, open throttle control and crank

Remove and clean.

Clean, adjust the gap or replace.

Open valve.

Remove and clean.

Check or change oil.

Clean, adjust the gap, or replace.

Time engine.

Replace couplers or coupler insert.

45

bar) of nitrogen.

Recharge with approximately

540-660

psi '(37-

Replace accumulator.

Examine the valve seats for wear and pitting.

Replace if necessary.

Arrange

a

barrel or tank

to

collect discharged

water from

pump.

Compare this to the rated

capacity

to

see if the discharge has actually

decreased.

4

307-308