Maintenance

Owner’s Manual for Stationary Emergency Generators 43

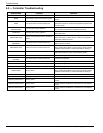

Figure 5-15. Adjust Spark Plug Gap

5. Check condition of threads in cylinder head and on spark plugs. If necessary, soften deposits with penetrating oil

and clean out with a thread chaser.

6. Clean spark plugs using a wire brush and commercial solvent. Do not blast spark plugs. Use new spark plugs if

necessary.

7. See B of Figure 5-15 Check spark plug gap using a wire feeler gauge. Adjust gap by carefully bending ground

electrode as follows:

8. Finger tighten spark plugs into cylinder head, and then using a spark plug socket, tighten as follows:

9. Install spark plug cables onto spark plug terminals.

10. Verify that spark plug cables are captured in cable clips at top of valve cover.

5.8.4— Final Instructions

If only performing Schedule A and Schedule B maintenance procedures, proceed as follows:

1. Install battery negative cable (black) onto battery negative (-) terminal.

2. Install left and right side access panels. See Subsection 5.2 —Access Panels.

3. See Subsection 5.10 —Return To Service.

Spark Plug Gap

Model 22/27 kW 25/30 kW 32/38 kW 36/45 kW 48 kW 60 kW

Engine 2.4L 1.5L 2.4L 2.4L 5.4L 2.4L

0.71 mm (0.028 in.)

0.9 mm (0.035 in.)

1.07-1.17 mm (0.042-0.046 in.)

1.29-1.45 mm (0.051-0.057 in.)

Spark Plug Torque

Engine ft-lbs N-m

1.5L, 2.4L

18 25

5.4L

13 18

A B