14

• Where electrolyte contacts the eyes, flush

thoroughly and immediately with water and

seek medical attention; and

• Spilled electrolyte is to be washed down with

an acid neutralizing agent. A common practice

is to use a solution of 1 pound (500 grams)

bicarbonate of soda to 1 gallon (4 liters) or

water. The bicarbonate of soda solution is to

be added until the evidence of reaction (foam-

ing) has ceased. The resulting liquid is to be

flushed with water and the area dried.

3.10 MAJOR SERVICE MANUAL

To obtain a service manual for the generator, contact the near-

est Authorized Service Dealer. Make sure to identify the MODEL

NUMBER and SERIES.

3.11 EXERCISING THE GENERATOR

The manufacturer recommends that the generator be started and

operated at least once every seven days. Let the unit run for at

least 30 minutes to “exercise” the engine.

3.12 OUT OF SERVICE PROCEDURE

3.12.1 REMOVAL FROM SERVICE

If the generator cannot be exercised every seven days, and it is to

be out of service longer than 30 days, prepare the generator for

storage as follows:

1. Start the engine and let it warm up.

2. Close the fuel shutoff valve in the fuel supply line and allow

the unit to shut down.

Note:

Using a fuel additive such as STA-BIL fuel stabilizer, or an

equivalent, will prevent gum deposits from forming in the

engine’s fuel system.

3. While the engine is still warm from running, drain the oil com-

pletely. Refill the crankcase with SAE 10W-30 oil having API

classification “For Service SF.”

4. Attach a tag to the engine indicating the viscosity and clas-

sification of the oil in the crankcase.

5. Remove the spark plug and pour two or three tablespoons of

clean, fresh engine oil into the spark plug threaded openings.

Reinstall and tighten the spark plug.

6. Remove the battery and store it in a cool, dry room on a

wooden board. Never store the battery on any concrete or

earthen floor.

7. Clean and wipe the entire generator.

3.12.2 RETURN TO SERVICE

To return the unit to service after storage, proceed as follows:

1. Check the tag on the engine for oil viscosity and classification.

Verify that the correct recommended oil is used in the engine

(see "Engine Oil Requirements"). If necessary, drain and refill

with the proper oil.

2. Check the state of the battery. Fill all cells of unsealed batteries

to the proper level with distilled water. DO NOT USE TAP WATER

IN THE BATTERY. Recharge the battery to 100 percent state of

charge, or, if defective, replace the battery.

3. Clean and wipe the entire generator.

4. Reconnect the battery. Observe battery polarity. Damage may

occur if the battery is connected incorrectly.

5. Turn OFF all electrical loads. Add fuel if necessary and then

start the engine.

6. Allow the unit to run for several minutes to warm up.

7. Apply electrical loads to at least 50 percent of the unit’s rated

wattage capacity.

8. When the engine is thoroughly warmed up, shut it down.

9. The generator is now ready for service.

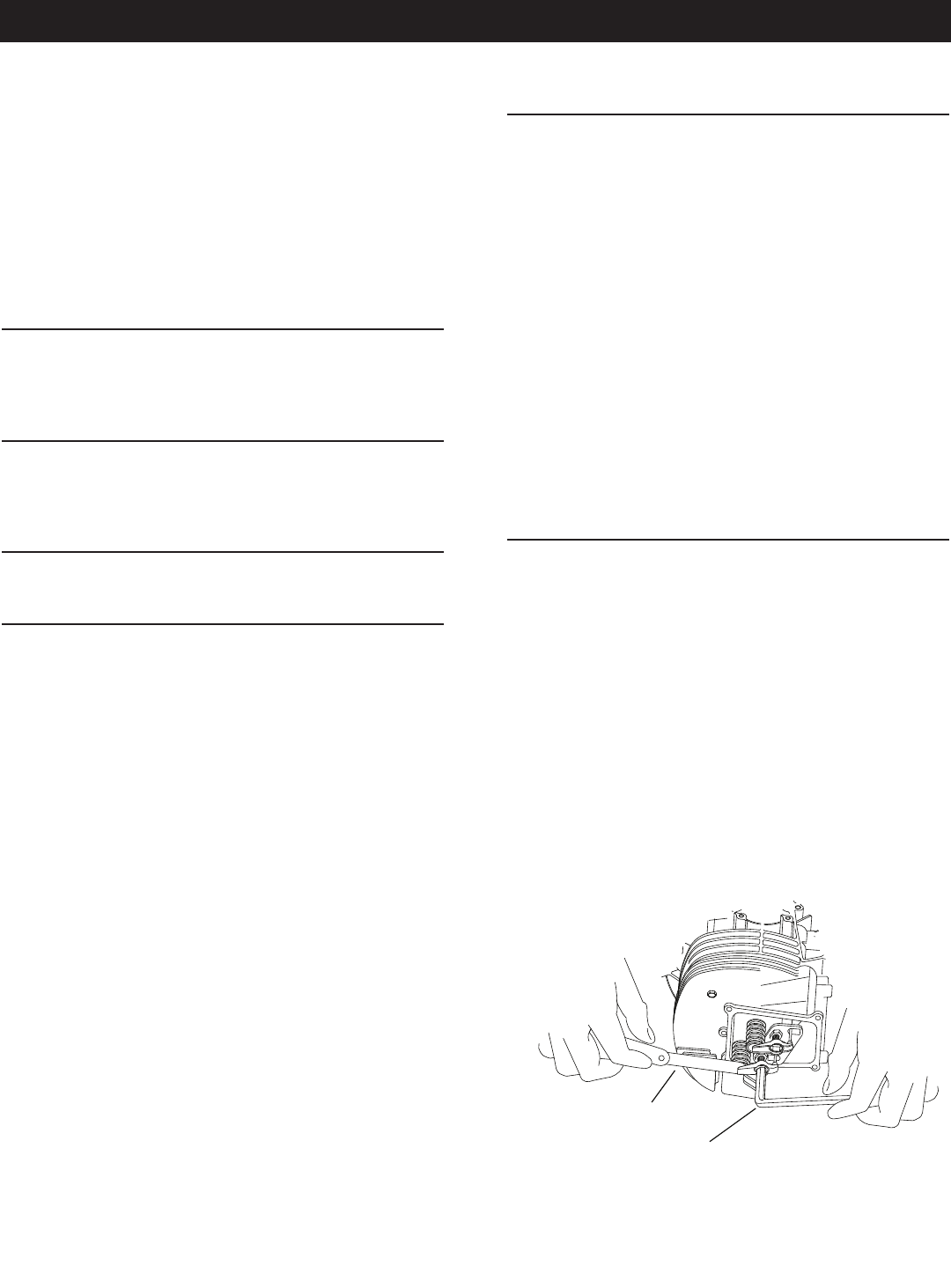

3.13 ADJUSTING VALVE

CLEARANCE

After the first 50 hours of operation, adjust the valve clearance in

the engine.

When adjusting valve clearance, the engine should be at room

temperature and the piston should be at Top Dead Center (TDC)

of its compression stroke (both valves closed). Correct clearance

is 0.001-0.003 inch (0.03-0.07mm). Adjust valve clearance as

follows:

1. Loosen the rocker arm jam nut. Use an allen wrench to turn

the pivot ball stud while checking clearance between the

rocker arm and the valve stem with a feeler gauge (Figure

3.7).

Figure 3.7 — Adjusting Valve Clearance

FEELER GAUGE

ALLEN WRENCH

Maintenance