13

INSTALLATION

Important!

VENTILATION

A minimum building ventilation rate of 4 CFM per 1,000 BTU’s of installed heater input must be provided. This

rate of ventilation may be obtained through either gravity or mechanical ventilation of the building. In con-

junction with building ventilation system, adequate fresh air into the building must be provided through fresh

air inlets and/or building inlets. It is recommended local code be checked to assure the ventilation system and

heat installation are in compliance with local and/or state codes.

When checking for gas leaks, do not use an open flame. Use a soap and water solution.

Note:

Gas connections on the heater are leak tested at the factory prior to shipment.

WARNING!

■ Periodically check the whole gas system for leaks or immediately check if the smell of gas is detected.

Extinguish all open flames.

■ Never leak test while smoking.

■ Do not use heater until all connections have been leak tested and do not leak.

■ When leak testing, refer to the connections diagrams.

■ Only those parts recommended by the manufacturer should be used.

■ Substitution can void warranty.

LEAK TEST:

Make a soap solution of one part liquid detergent, and one

part water. The soap solution can be applied with a spray

bottle, brush or rag. Soap bubbles will appear where a leak is

present.

Turn the gas supply “ON” check for leaks at leak points. If a

leak is present, turn off supply, tighten any leaking fittings,

turn gas on and recheck.

Note:

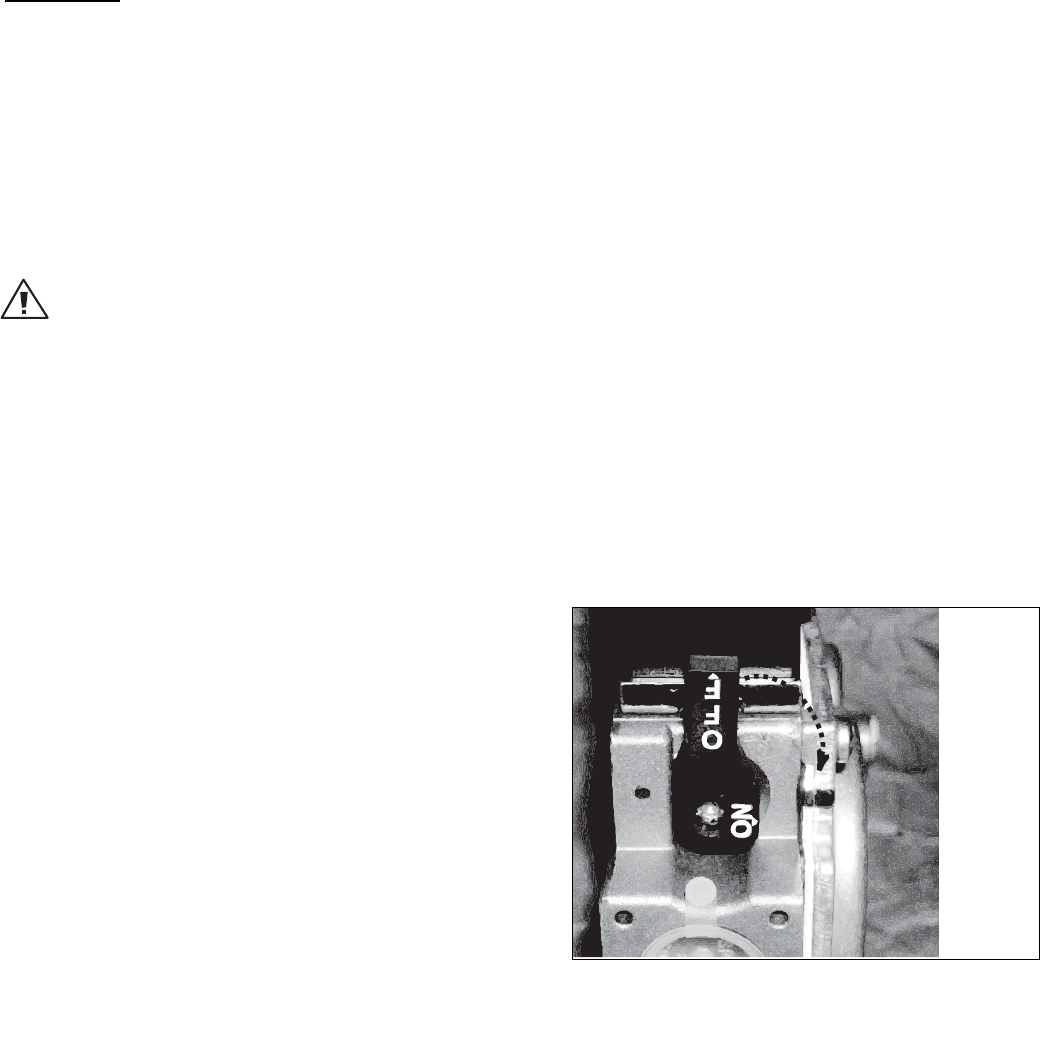

There is a manual shut-off lever on the internal heater control

valve/regulator. This lever is shipped in the “ON” position -

Fig. 02 (Default position).

"ON" POSITION

FACTORY DEFAULT

"OFF"

Fig. 02