14

Regular

Maintenance

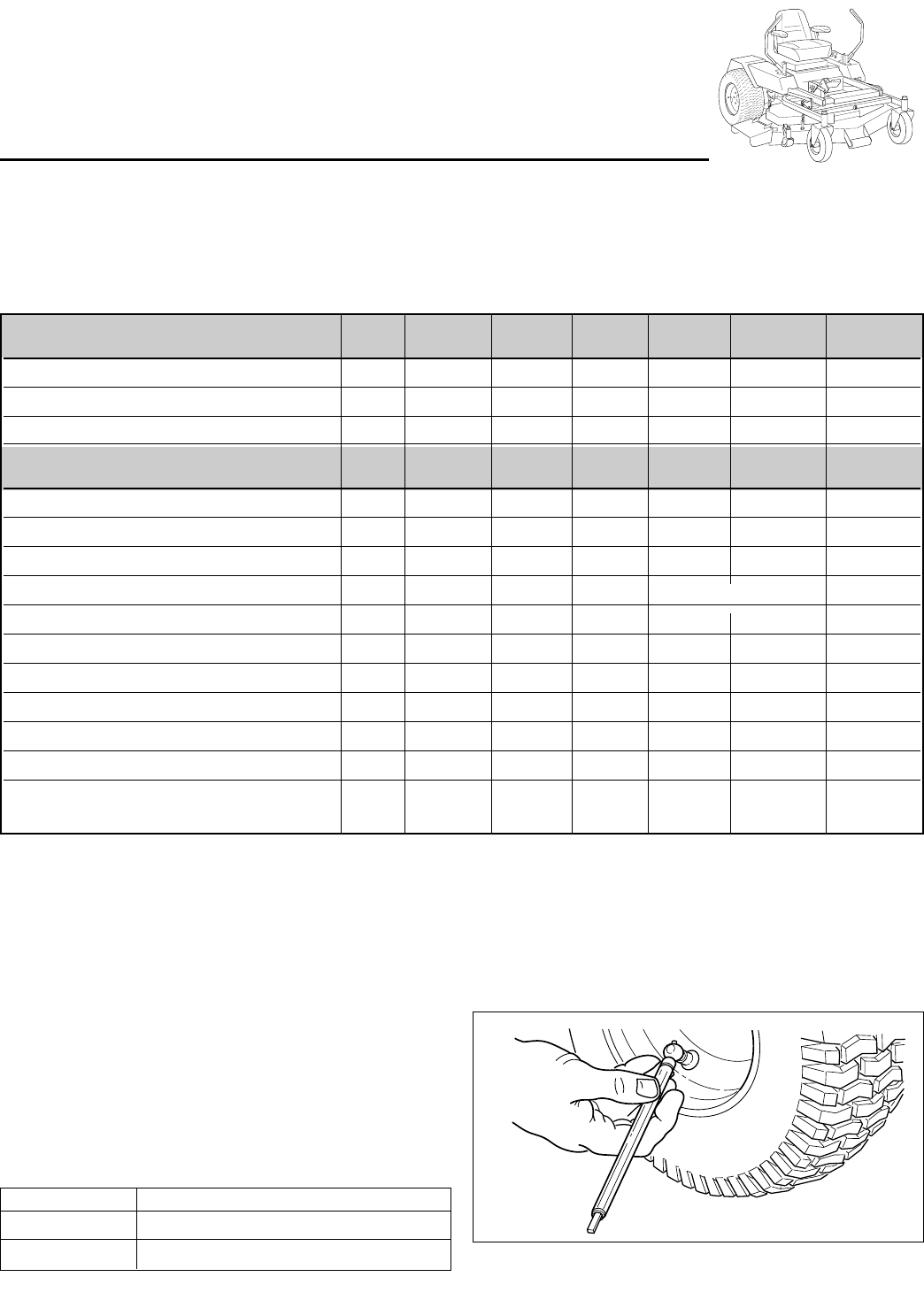

MAINTENANCE SCHEDULE & PROCEDURES

The following schedule should be followed for normal care of your rider and mower. You will need to keep a record

of your operating time. Determining operating time is easily accomplished by observing the hour meter.

SSeeee BBeeffoorree BBeeffoorree EEvveerryy EEvveerryy EEvveerryy SSpprriinngg

SSAAFFEETTYY IITTEEMMSS PPaaggee FFiirrsstt UUssee EEaacchh UUssee 55 HHoouurrss 2255 HHoouurrss 110000 HHoouurrss && FFaallll

Check Safety Interlock System 7 X X

Check Rider Brakes 22 X X

Check Mower Blade Stopping Time 23 X X

SSeeee BBeeffoorree BBeeffoorree EEvveerryy EEvveerryy EEvveerryy SSpprriinngg

NNOORRMMAALL CCAARREE IITTEEMMSS PPaaggee FFiirrsstt UUssee EEaacchh UUssee 55 HHoouurrss 2255 HHoouurrss 110000 HHoouurrss && FFaallll

Check Rider/Mower for loose hardware — X X

Check Engine Oil Level 15* X X X X

Check Engine Air Filter 15* X ***X

Change Engine Oil & Filter ** 15* ***X Every 50 Hours ***X

Lubricate Rider & Mower 16 ***X

Check Tire Pressure 14 X ***X

Check Hydraulic Fluid 15 X ***X

Check Fuel Filter 15 X

Clean Battery & Cables 17 X

Clean & Sharpen Mower Blades 18 X

Inspect Spark Plug 15* X

* See the engine manufacturer's owner's manual.

** Change original engine oil after first 5 hours of operation.

*** More often in hot (over 85° F: 30° C) weather or dusty operating conditions.

Tire Pressure

Front 20 psi (138 kPa)

Rear 15 psi (103 kPa)

Figure 9. Checking Tire Pressure

CHECK TIRE PRESSURES

Tire Pressure should be checked periodically, and main-

tained at the levels shown in the chart. Note that these

pressures may differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures

shown provide proper traction, improve cut quality, and

extend tire life.